Display device and manufacturing method thereof

A technology for display devices and light guide plates, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc. It can solve the problems of widening the frame and achieve the effects of reducing width, improving utilization rate, and shortening the light mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

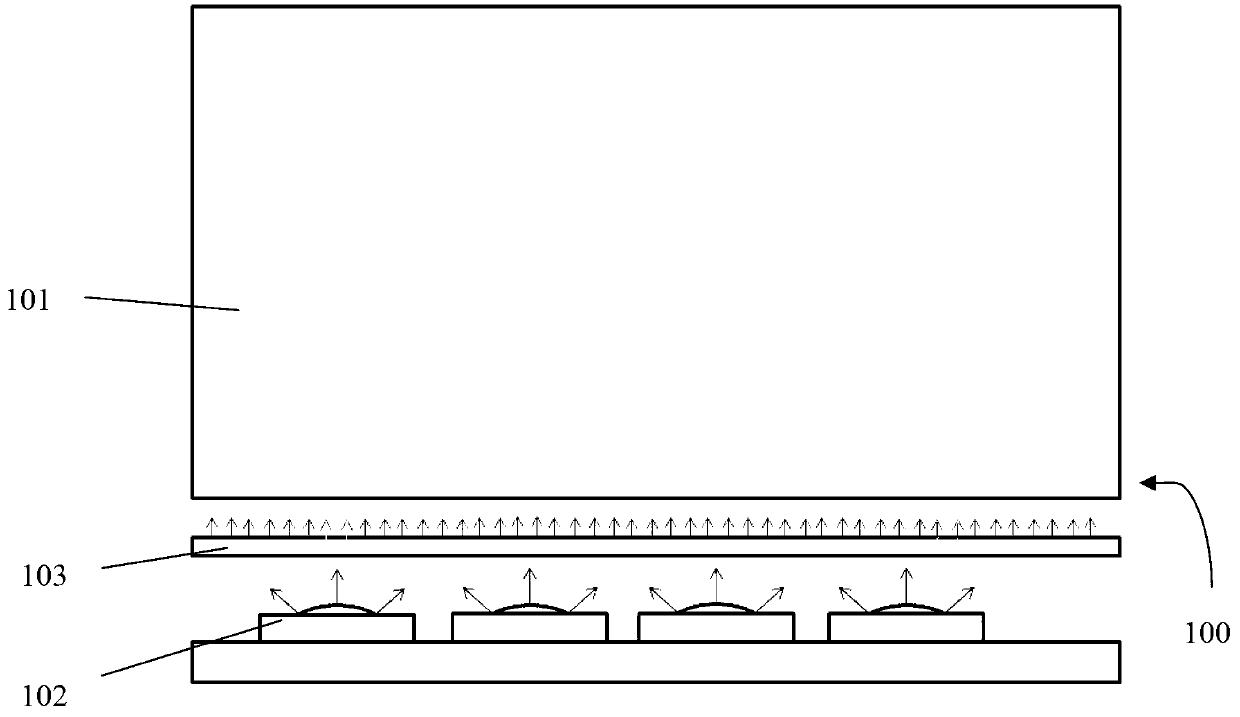

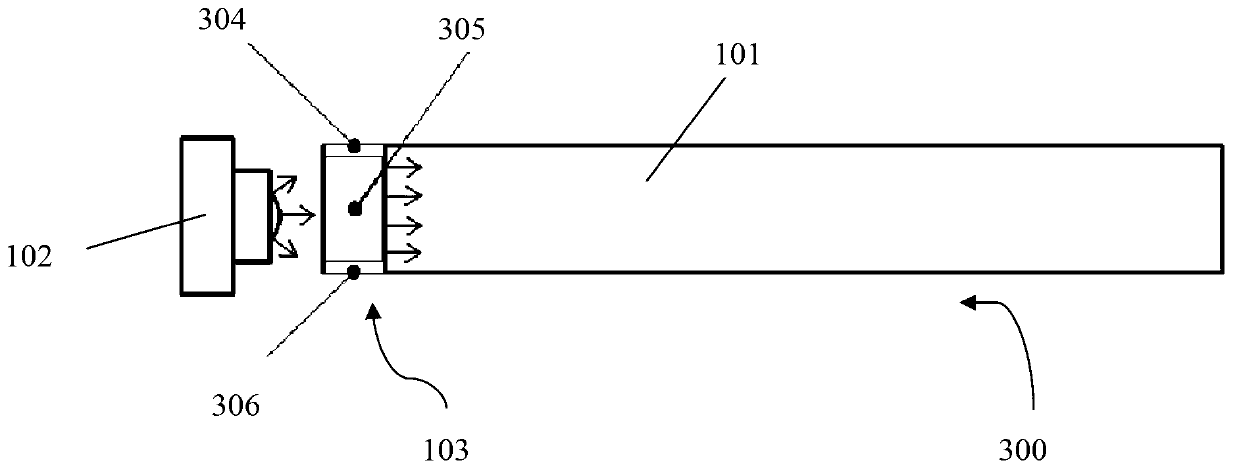

[0027] figure 1 The main structure of the display device 100 according to the present invention is schematically shown.

[0028] The display device 100 includes a light guide plate 101 for guiding the light path, a light emitting element 102 located on one side of the light guide plate 101 , and a light mixing unit 103 located between the light guide plate 101 and the light emitting element 102 .

[0029] The light mixing unit 103 can make the light from the light emitting element 102 take place in one or more of scattering, refraction and diffusion (see figure 2 ), thereby greatly changing the propagation path of the light emitted by the light emitting element 102, and finally reducing the light mixing distance of the light emitting element 102 (that is, the distance at which the uneven light source of the light emitting element 102 is mixed into a uniform su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com