Automatic ignition linear type combustor

An ignition wire and burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of low mixed gas injection flow rate, inconsistent flame height, low burner power, etc., to ensure rigidity and stability The effect of ensuring the uniformity of mixing and strengthening the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

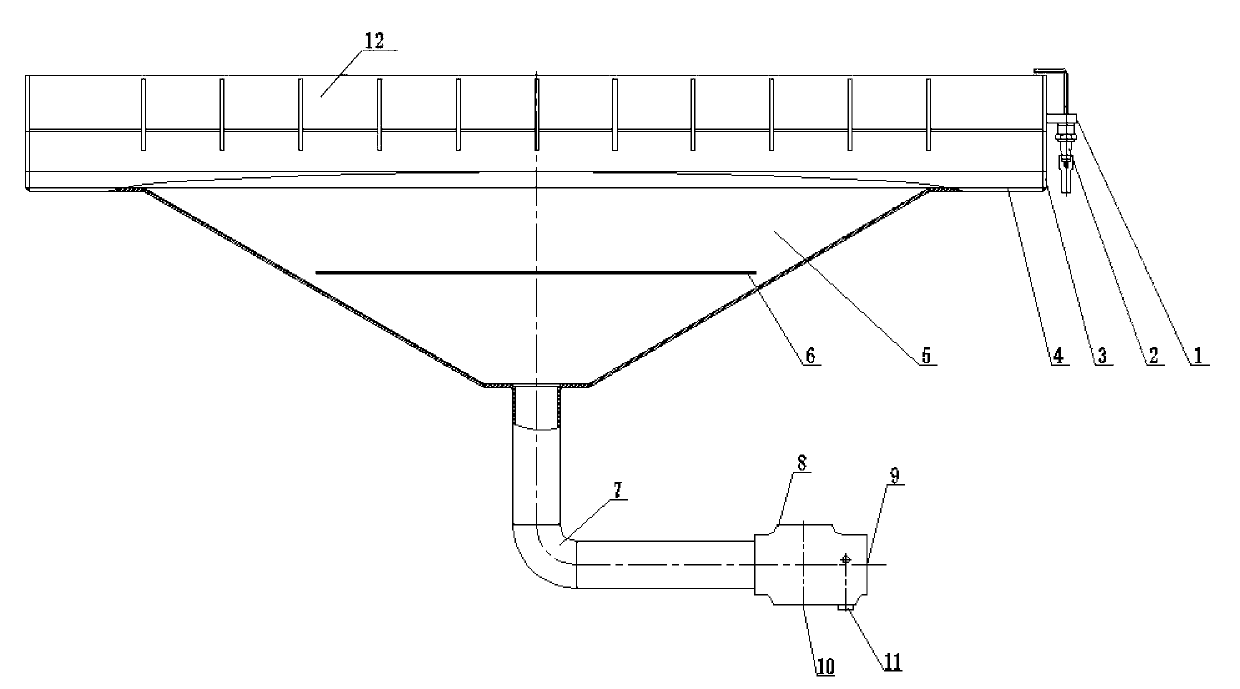

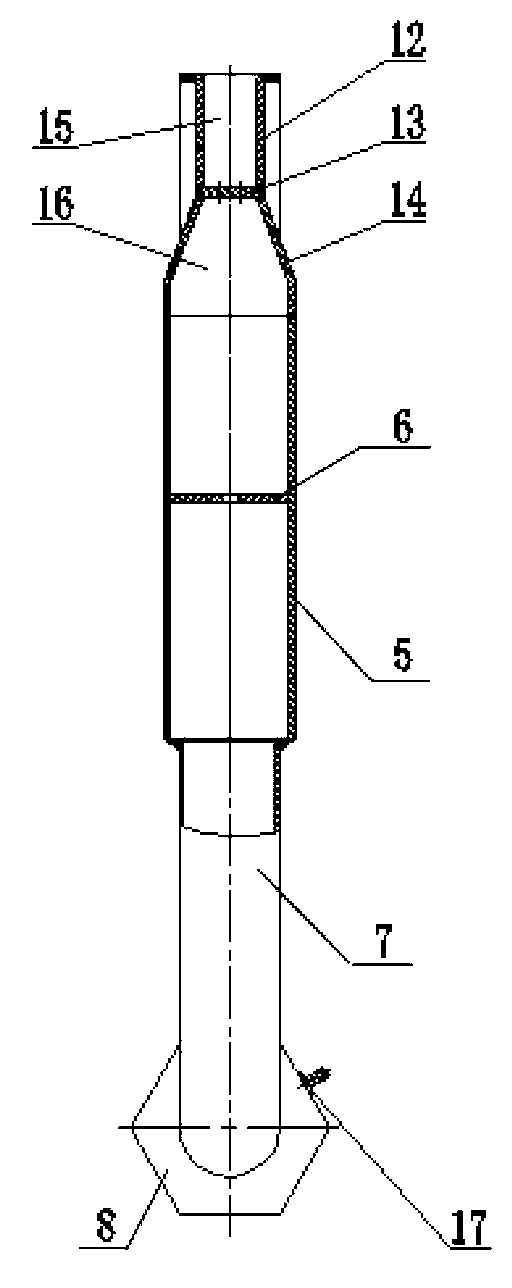

[0025] Such as Figure 1-Figure 3 As shown, the autoignition wire burner of the present invention includes an ignition electrode 2 , a nozzle plate 13 , an open gas collecting box 5 , a gas distribution plate 6 , a gas mixture pipeline 7 and a mixer 8 .

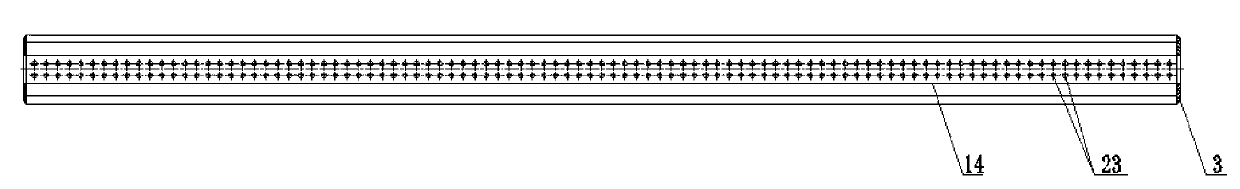

[0026] The nozzle plate 13 is provided with a plurality of nozzle holes 23 . The nozzle plate 13 is formed by heat-resistant steel, and its length and width are determined according to the technological requirements of the heated parts. The size and number of nozzle holes 23 are determined by calculation according to the flame characteristics required by the actual situation of the application and the type of fuel used. In general, the faster the combustion speed of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap