Method and device for detecting radial drift of rotating body based on electrostatic sensor array

An electrostatic sensor and detection device technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of sensitivity to magnetic interference, high price, harsh environmental requirements, etc., and achieve reliable drift, simple structure, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention provides an automatic detection method and device for radial drift of a rotating body based on an electrostatic sensor array. Below in conjunction with accompanying drawing and embodiment the present invention is described as follows:

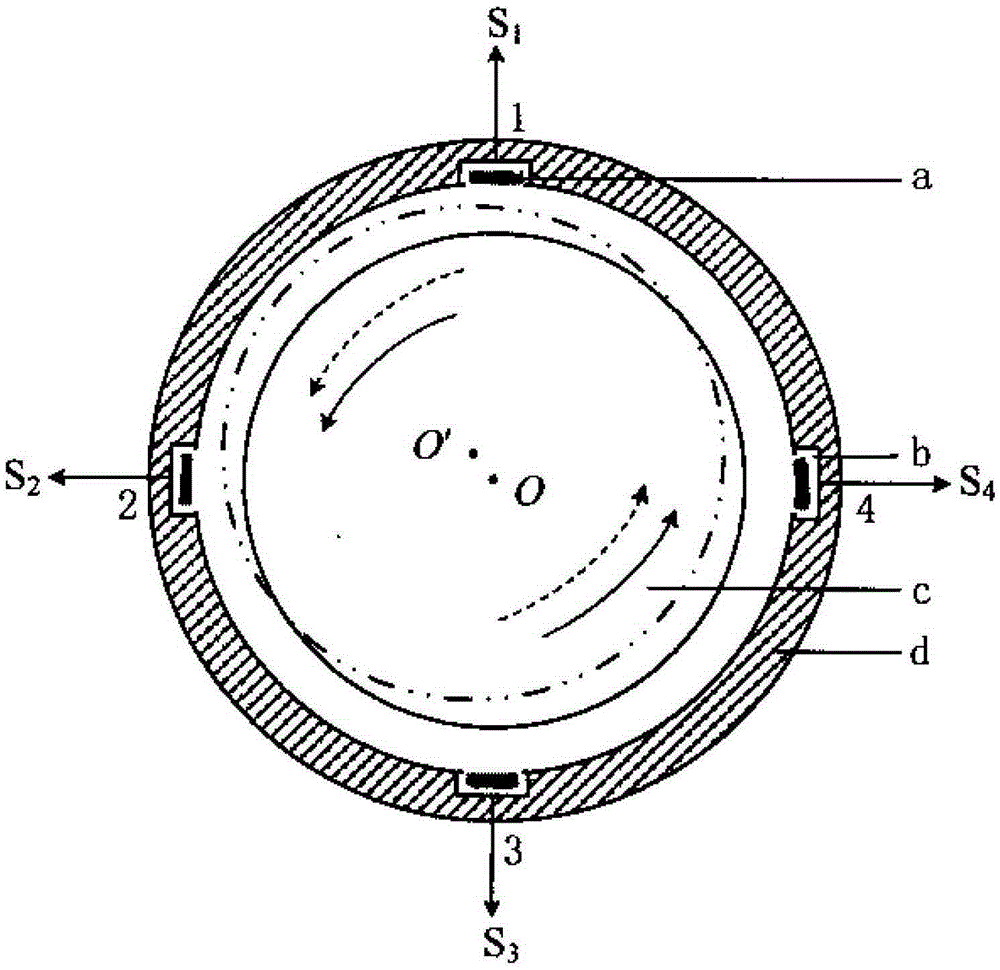

[0026] figure 1 Shown is a schematic structural diagram of the electrostatic sensor array in the automatic detection device for the radial drift of the rotating body based on the electrostatic sensor array. In the figure, the composition of the automatic detection device for the radial drift of the rotating body of the electrostatic sensor array: the electrostatic sensor a is evenly distributed on the periphery of the measured rotating body c and is equidistant from the axis O of the rotating shaft, and is installed on the inner wall of the metal shielding shell d on, such as figure 1 Electrodes 1, 2, 3, and 4 in the electrode form an electrostatic sensor array; the surface of each electrostatic sensor a is coated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com