Axle testbed for axle assembly running-in test

A technology for test benches and axles, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as unsatisfactory, time-consuming and labor-intensive, and low work efficiency, and achieve simple structure and improved work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

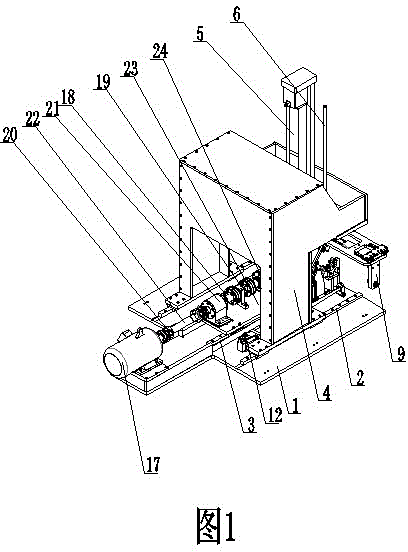

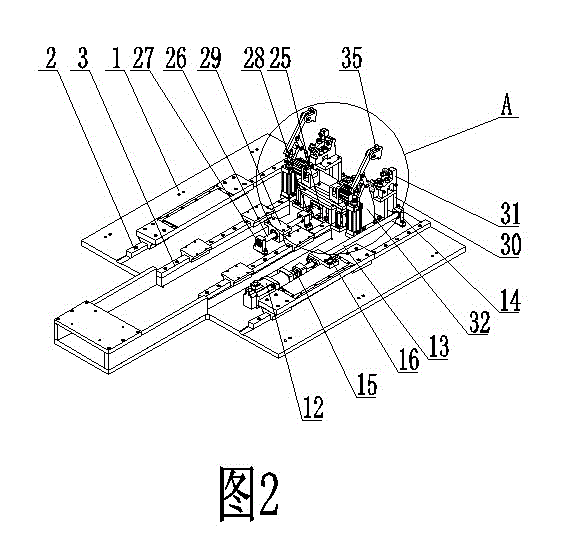

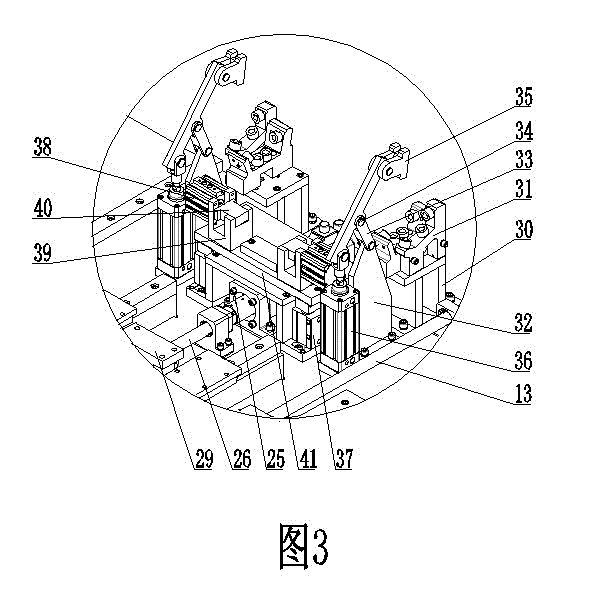

[0020] The axle test bench for the running-in test of the axle assembly consists of a mounting base 1, a grabbing device, an automatic centering running-in device, a sliding screw drive device, a translation screw drive device, a lifting clamping device, a program control device, The linear guide rail 2 and the sliding track 3 are formed, and the grabbing device is movably installed on the mounting base 1 through the symmetrical linear guide rail 2 . The grabbing device is composed of a grabbing slide bracket 4, a servo electric cylinder 5, a guide rod 6, a locking cylinder 7, a wide air claw 8, a clamping head 9 and a mounting plate 10. A servo electric cylinder 5 is fixedly installed on the front end of the top of the grasping sliding bracket 4, and the end of the piston rod of the servo electric cylinder 5 is fixedly equipped with a mounting plate 10. Both sides of the servo electric cylinder 5 are equipped with guide rods 6 through linear bearings, and the guide rods 6 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com