Vehicle bumper structure

A technology for bumpers and vehicles, applied in bumpers, vehicle parts, vehicle safety arrangements, etc., can solve problems such as waste of design space and complex interval management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be described in detail based on the illustrated embodiments.

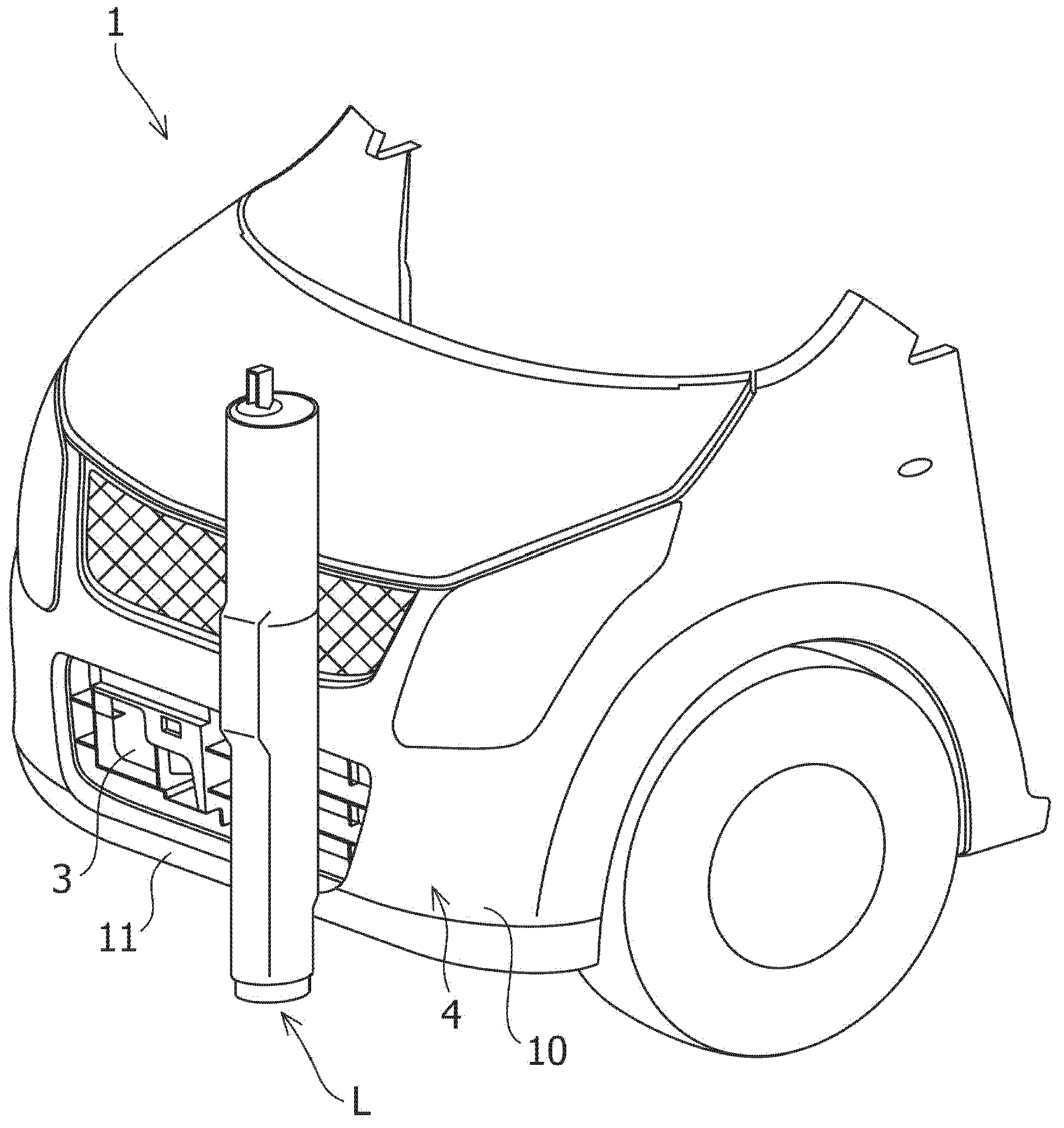

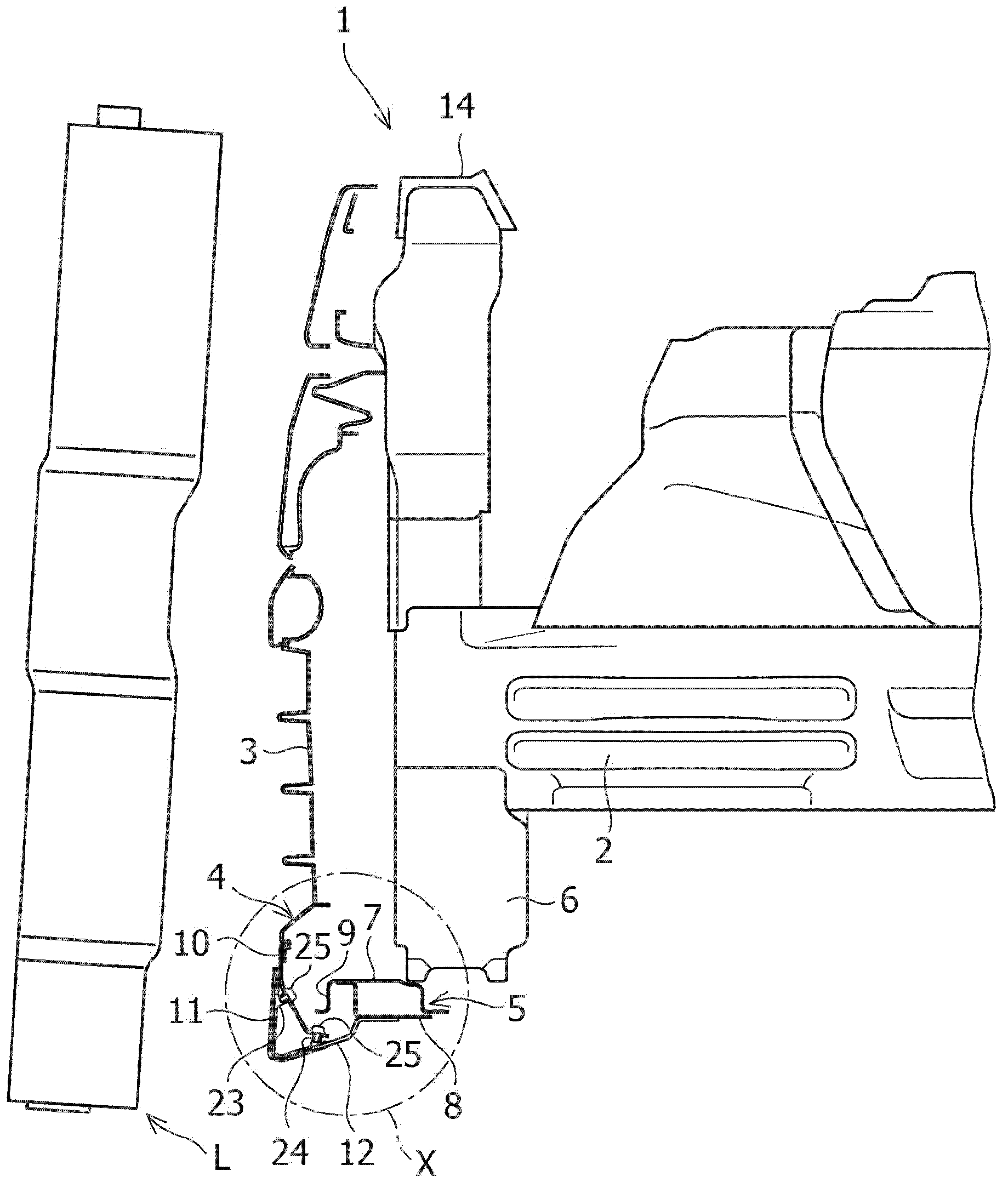

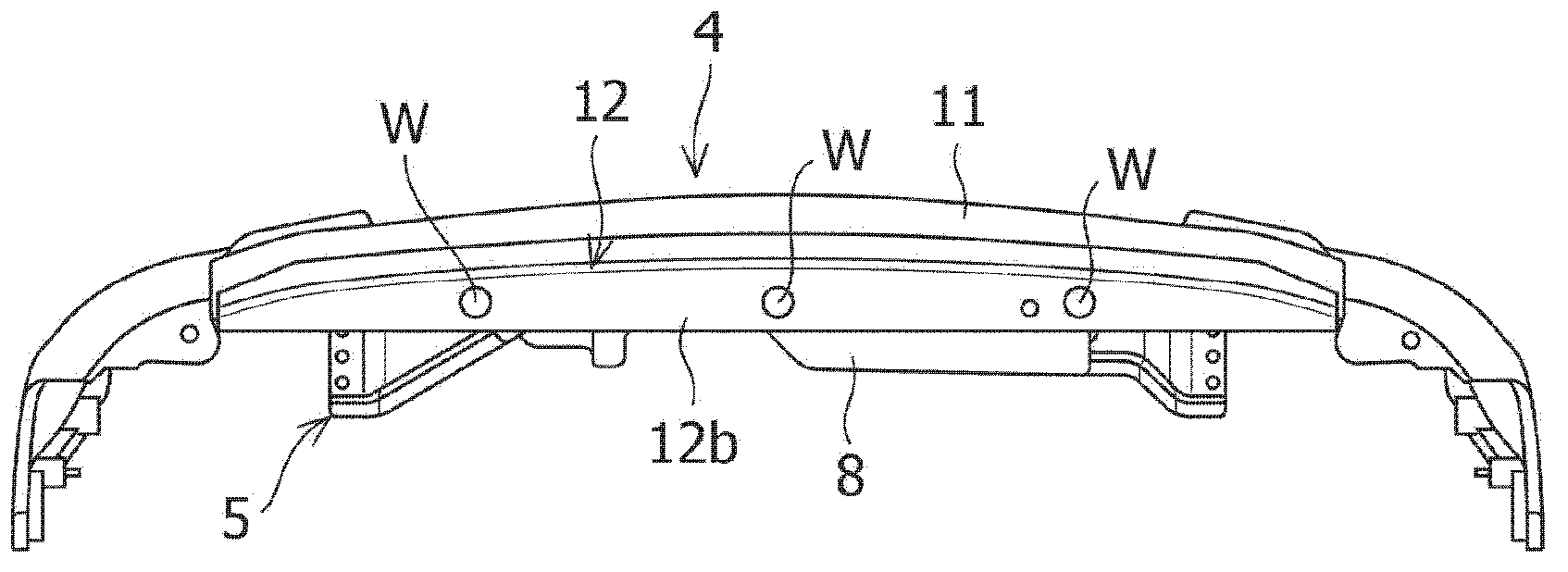

[0036] Figure 1 to Figure 5 A bumper structure of a vehicle according to an embodiment of the present invention is shown.

[0037] Such as figure 1 and figure 2 As shown, the vehicle front 1 to which the bumper structure according to the embodiment of the present invention is applied mainly includes: a pair of left and right apron side members (apron side members) 2 extending along the front-rear direction of the vehicle with an intervening The left and right sides in the vehicle width direction are arranged with gaps; and the resin bumper grille 3 and the front bumper 4 located in front of the vehicle of these skirt side members 2, the bumper grille 3 is arranged on the back side of the front bumper 4 .

[0038] In the vehicle front portion 1 of the present embodiment, the pedestrian's leg L extending in the vehicle up-down direction is located on the vehicle l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com