Powder metallurgy gear front and back automatic recognition device

A technology of powder metallurgy and automatic identification, which is applied in the direction of measuring devices, metal processing, metal processing equipment, etc., can solve problems such as chipping and misoperation, and achieve the effect of avoiding quality problems, eliminating chipping phenomena, and eliminating quality hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

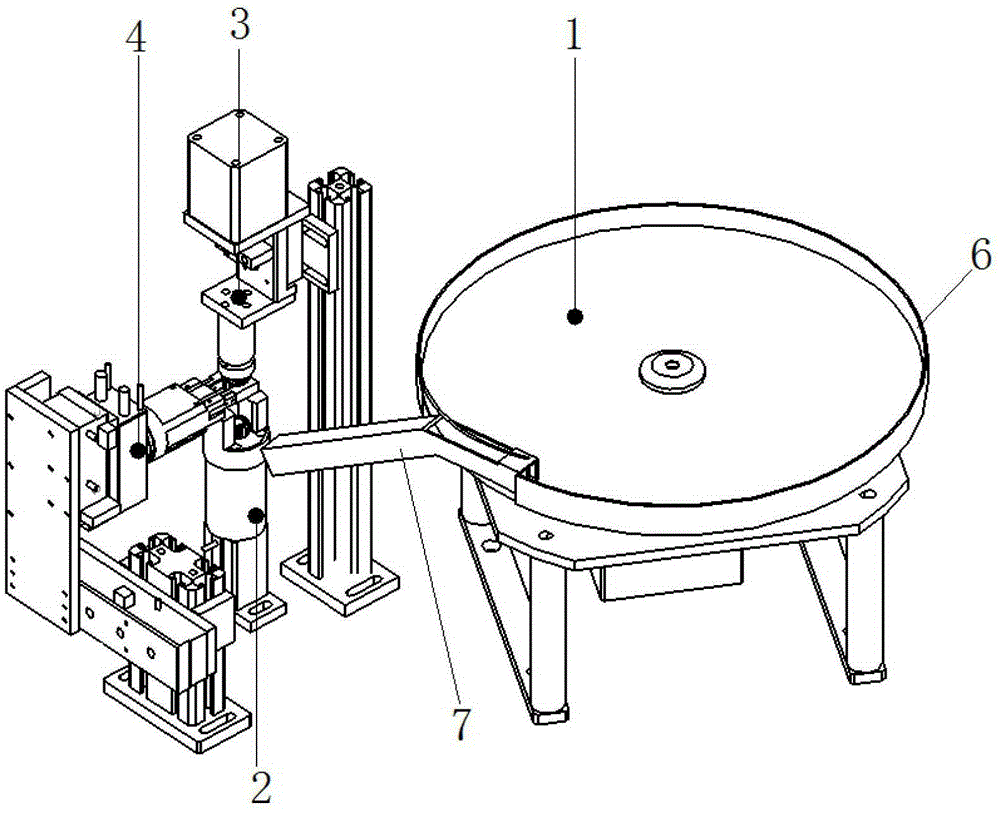

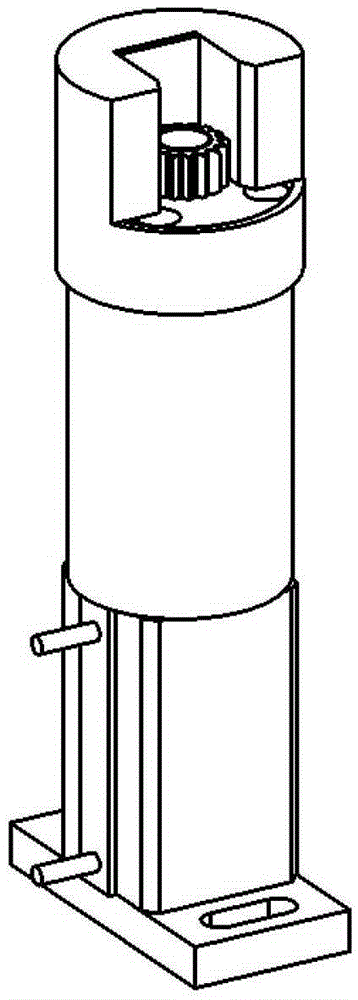

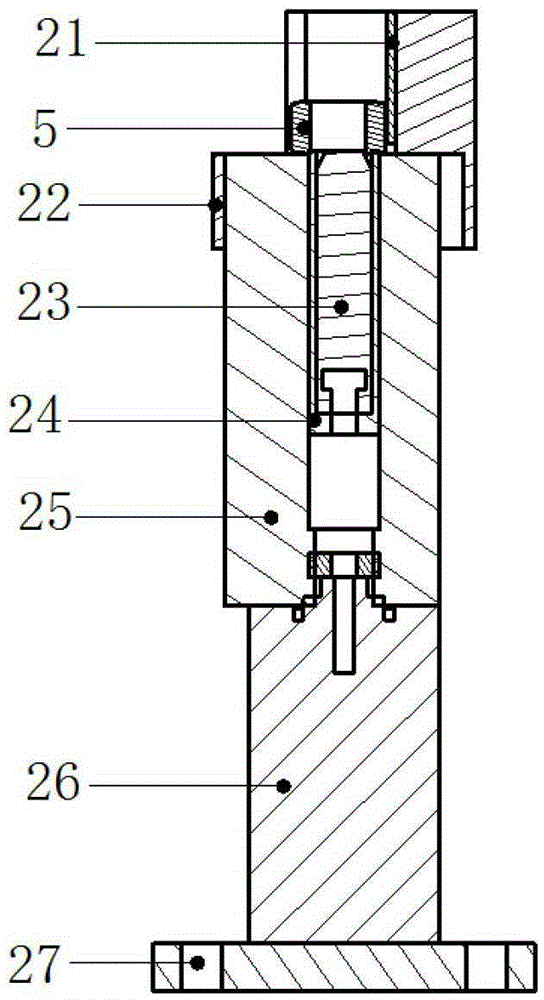

[0031] Such as figure 1 As shown, the powder metallurgy gear front and back automatic recognition device of the present invention includes a feeding system 1, a lifting system 2, a recognition system 3 and a correction system 4, and a powder metallurgy gear 5 ( image 3 As shown) sequentially passes through the feeding system 1, the lifting system 2, through the identification system 3 to identify the front and back, and finally enters the correction system 4, and finally the action of identifying and correcting the front and back of the powder metallurgy gear 5.

[0032] Such as figure 1 As shown, the feeding system 1 includes a turntable 6 and a track 7 , and the powder metallurgy gear 5 is fed into the track 7 by the turntable 6 .

[0033] For the convenience of feeding, the identification system 3 is located below the rail 7 of the feeding system 1, and the rail 7 of the feeding system 1 is arranged on the edge of the turntable 6 and is inclined downward, so that the powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com