Efficient activated crushing stirrer

A kind of mixer, high-efficiency technology, applied in the direction of cement mixing device, chemical instrument and method, clay preparation device, etc., can solve the problems such as poor crushing effect, achieve the effect of good fluidity, enhanced strength, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

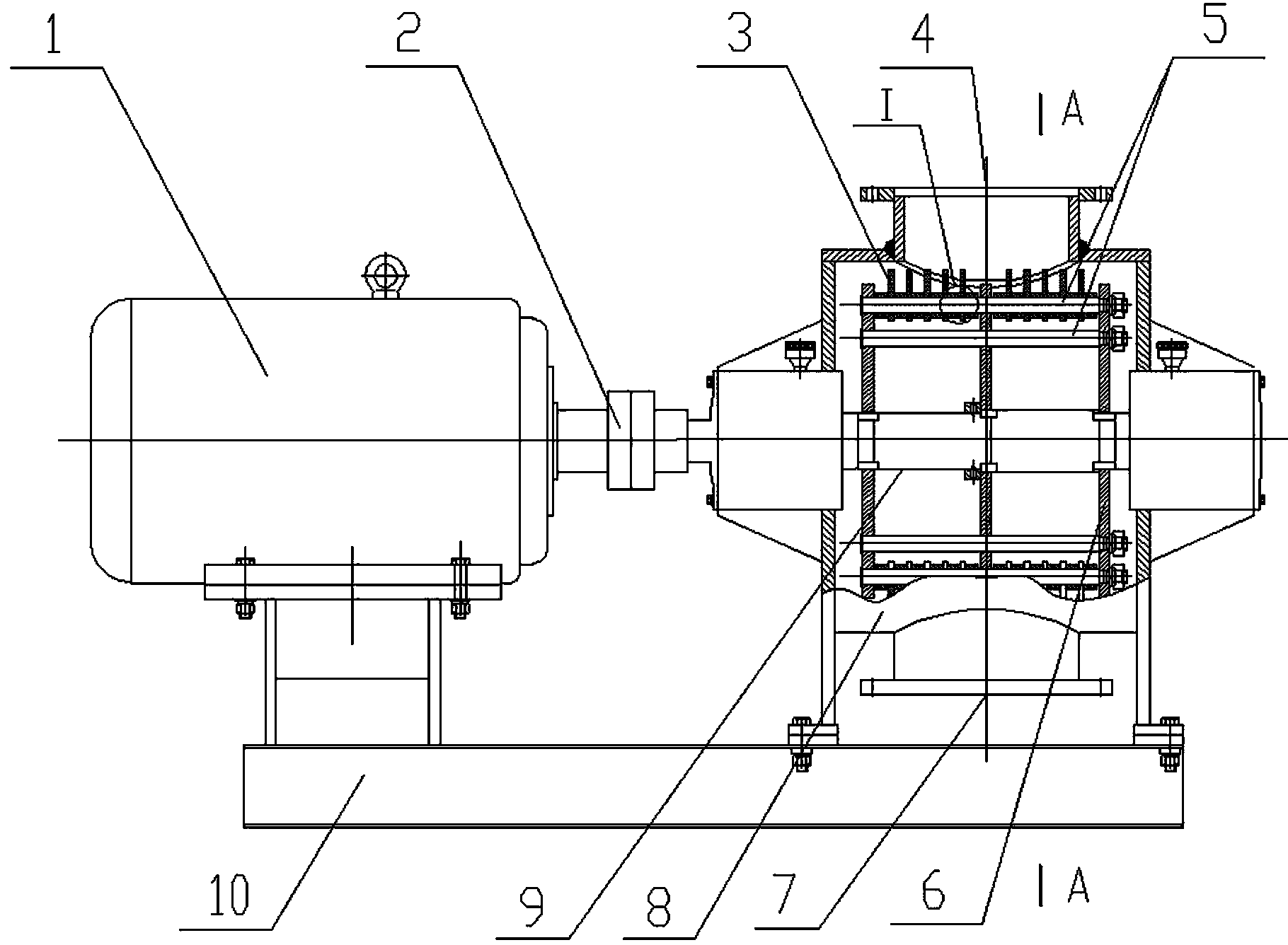

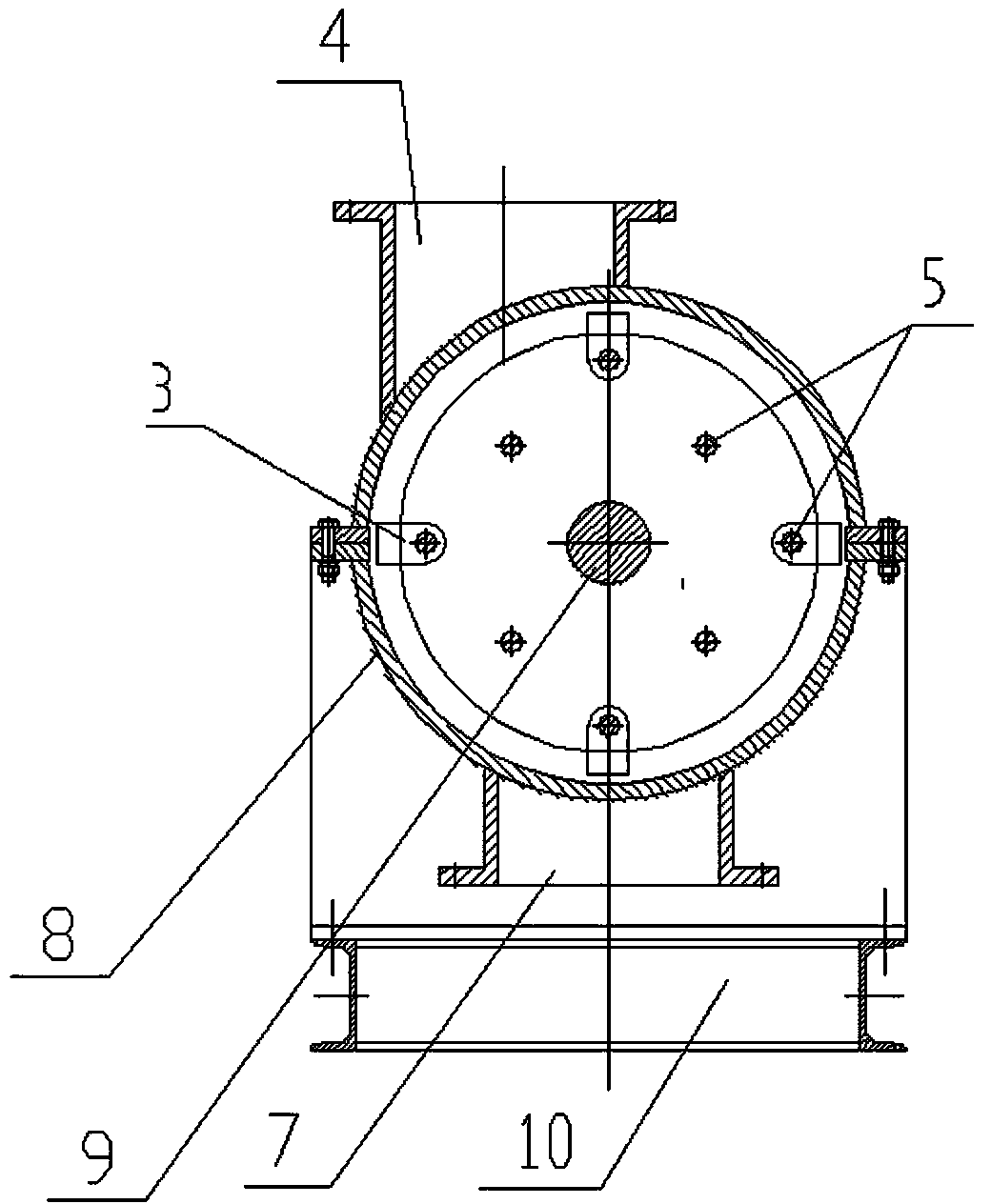

[0021] like figure 1 The high-efficiency activated crushing mixer shown includes a stirring chamber 8, a stirring main shaft 9, an agitating body arranged on the stirring main shaft 9, and a motor 1 that drives the stirring main shaft 9 to rotate. The top of the stirring chamber 8 is provided with a feed port 4, The bottom of the stirring chamber 8 is provided with a discharge port 7, and the feed port 4 and the discharge port 7 are located on the upper and lower sides of the stirring body.

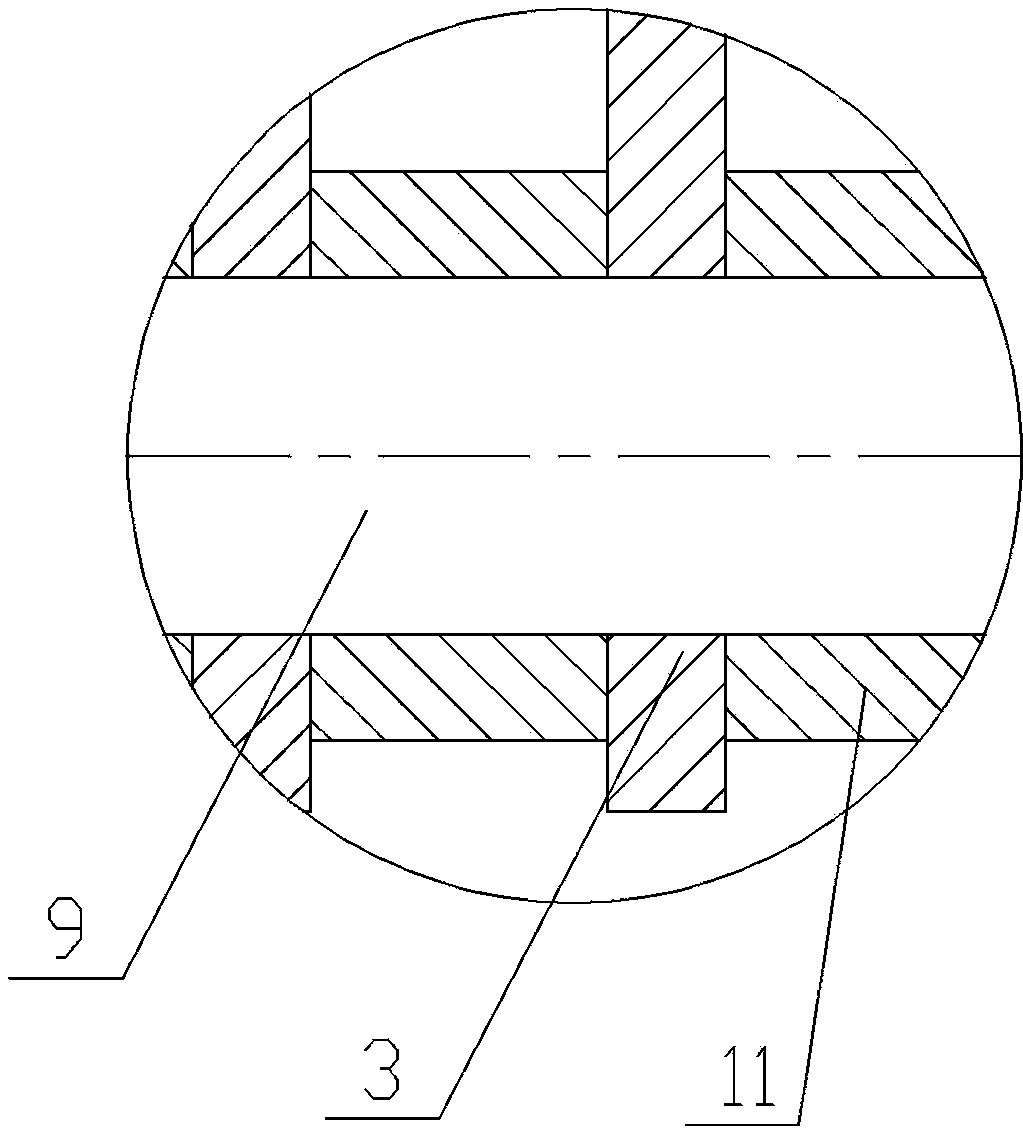

[0022] The agitating body includes eight stirring rods 5 parallel to the stirring main shaft 9 and fixed to the stirring main shaft 9. The eight stirring rods 5 are arranged in two circles around the outside of the stirring main shaft 9. There are four stirring rods in each circle. stagger. A plurality of breaking hammers 3 are rotatably connected to the stirring rod body 5 of the outer ring. Adjacent breaking hammers 3 are separated by spacers 11, and the spacers 11 are set on the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com