Plastic tray buckle locating device of full-automatic carton lifting handle eyeleting machine

A technology of plastic buckles and carton handles, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as the inability to guarantee high-efficiency and high-quality production operations, low production efficiency, and affecting the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

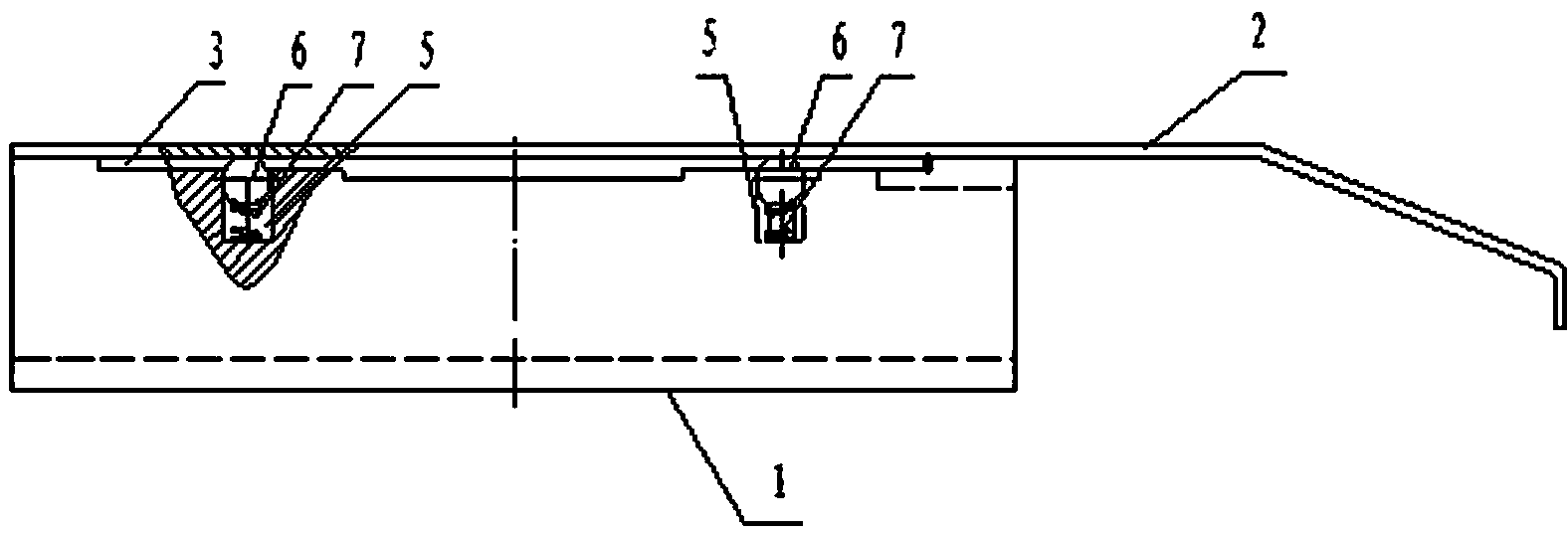

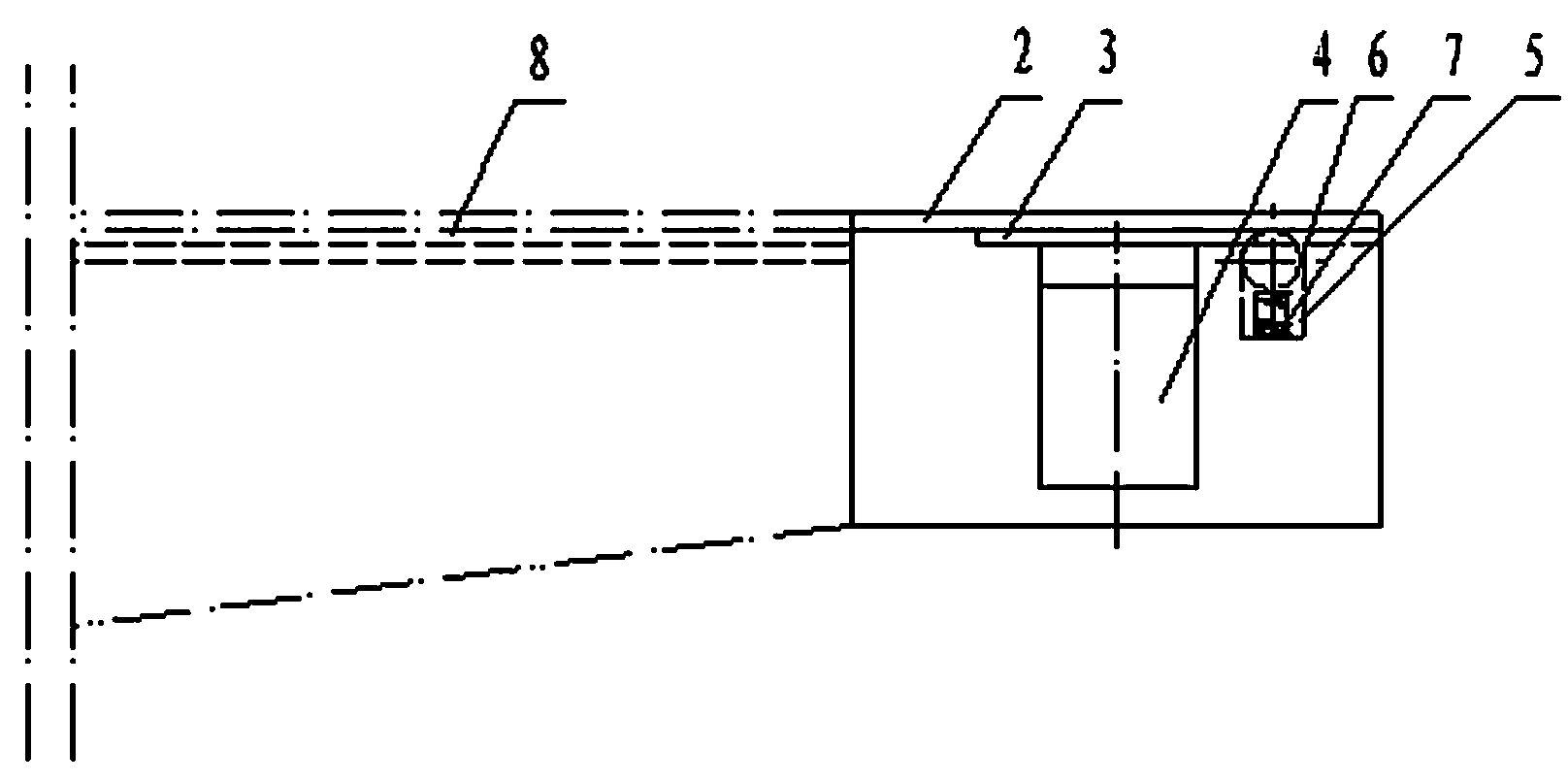

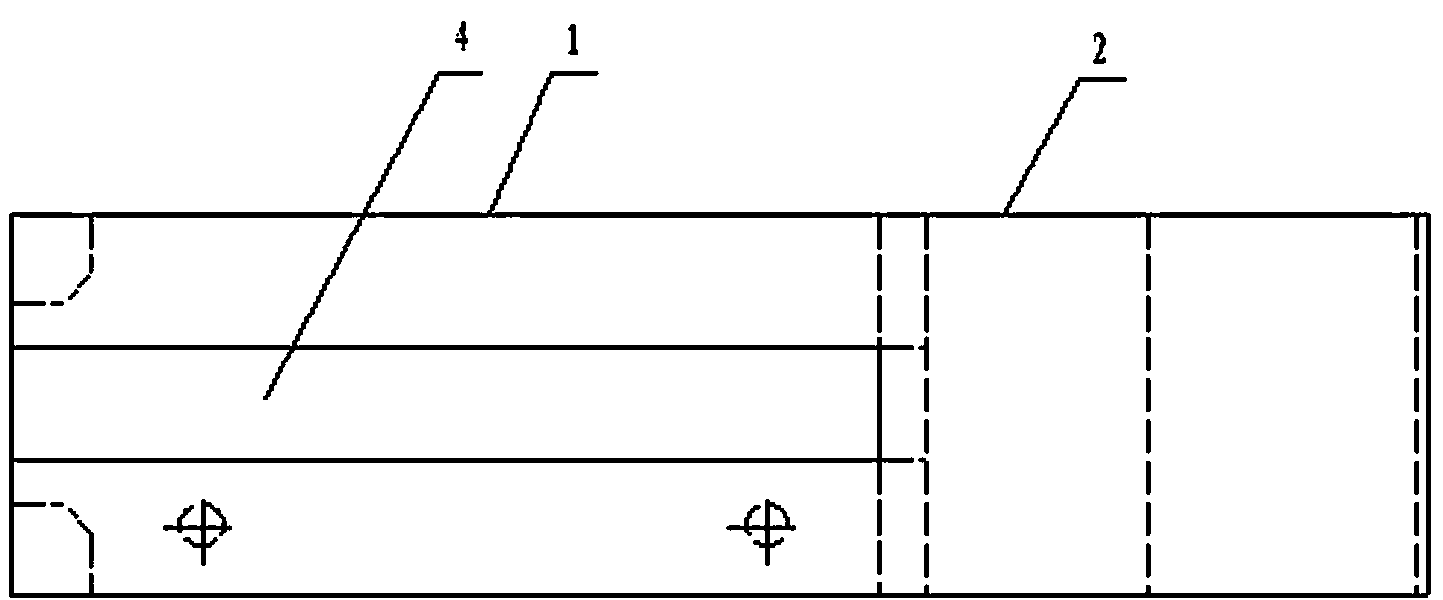

[0011] The plastic buckle positioning device of a fully automatic carton handle threading machine of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0012] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the plastic buckle positioning device of a fully automatic carton handle threading machine in this embodiment is composed of a positioning track block 1, a track groove cover plate 2 and a buckle positioning assembly. The upper surface of the positioning track block 1 is provided with a buckle track groove 3, and the depth of the buckle track groove 3 matches the thickness of the plastic buckle, the purpose is to ensure that the plastic buckle will not overlap when the buckle track groove 3 moves Phenomenon, in this embodiment, a track slot cover plate 2 is provided on the buckle track slot 3, a handle threading slot 4 is provided in the positioning track block 1, and a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com