Device and method for processing chemical wastewater with salinity higher than 10%

A chemical wastewater and salinity technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve enhanced treatment effect, mild reaction, and guaranteed electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

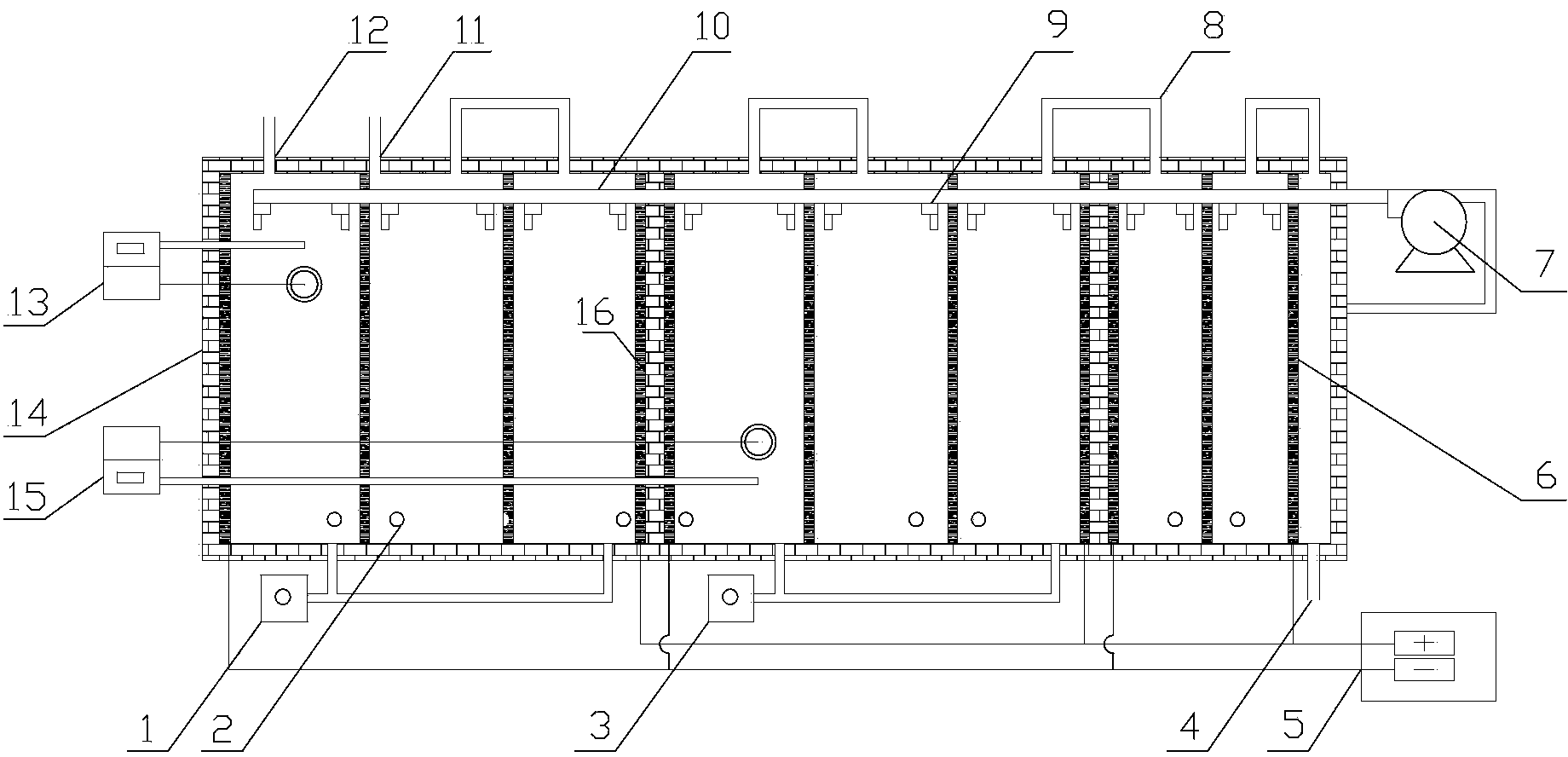

Method used

Image

Examples

Embodiment 1

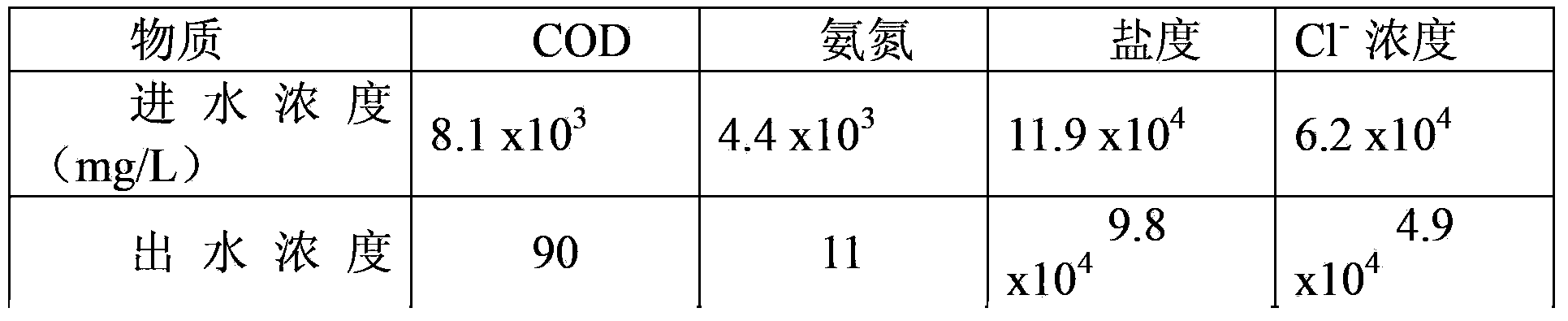

[0059] The treated water sample is high-salt, high-nitrogen, and high-organic medical wastewater, using the device and process flow of the present invention, wherein the current density in the first module is controlled to be 200A / m 2 , pH value is 7, hydrogen peroxide drop acceleration rate is 0.5ml·(h·L) -1 / g COD; the current density in the second module is 250A / m 2 , pH value is 5, hydrogen peroxide drop acceleration rate is 0.3ml·(h·L) -1 / g COD; the current density in the third module is 400A / m 2 . The raw water sample pollutants and the wastewater pollutants treated by this device are shown in Table 1.

[0060] Table 1 Salinity, ammonia nitrogen, COD indicators in water samples

[0061]

[0062]

Embodiment 2

[0064] The treated water sample is high-salt, high-nitrogen, and high-organic medical wastewater, using the device and process flow of the present invention, wherein the current density in the first module is controlled to be 250A / m 2 , pH value is 7, hydrogen peroxide drop acceleration rate is 1.0ml·(h·L) -1 / g COD; the current density in the second module is 300A / m 2 , pH value is 6, hydrogen peroxide drop acceleration rate is 0.2ml·(h·L) -1 / g COD; the current density in the third module is 500A / m 2 . The raw water sample pollutants and the waste water pollutants treated by this device are shown in Table 2.

[0065] Table 2 Salinity, ammonia nitrogen, COD indicators in water samples

[0066]

Embodiment 3

[0068] The treated water sample is high-salt, high-nitrogen, and high-organic medical wastewater, using the device and process flow of the present invention, wherein the current density in the first module is controlled to be 300A / m 2 , pH value is 6.5, hydrogen peroxide drop acceleration rate is 0.8ml·(h·L) -1 / g COD; the current density in the second module is 200A / m 2 , pH value is 5, hydrogen peroxide drop acceleration rate is 0.1ml·(h·L) -1 / g COD; the current density in the third module is 300A / m 2 . The raw water sample pollutants and the wastewater pollutants treated by this device are shown in Table 3.

[0069] Table 3 Salinity, ammonia nitrogen, COD indicators in water samples

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com