Rare earth molten salt electrolysis device based on anode adjustment and stable polar distance

A molten salt electrolysis device and the technology of the electrolysis device are applied in the field of rare earth molten salt electrolysis devices, which can solve the problems of unsteady electrolysis efficiency and quality of rare earth molten salts, and achieve the effect of ensuring electrolysis efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

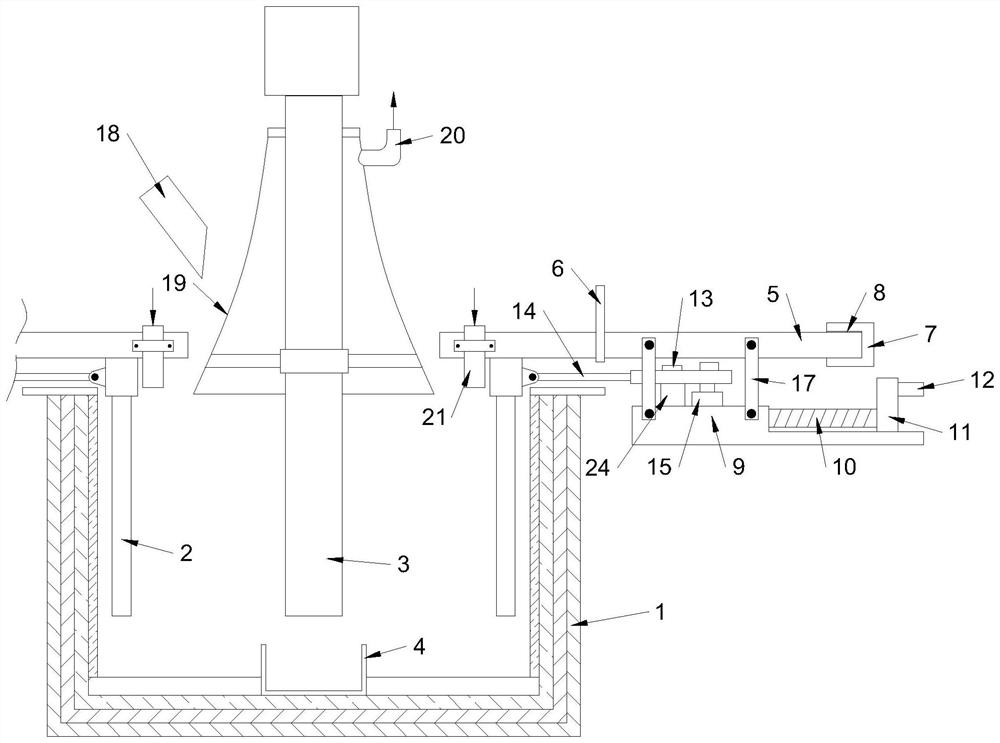

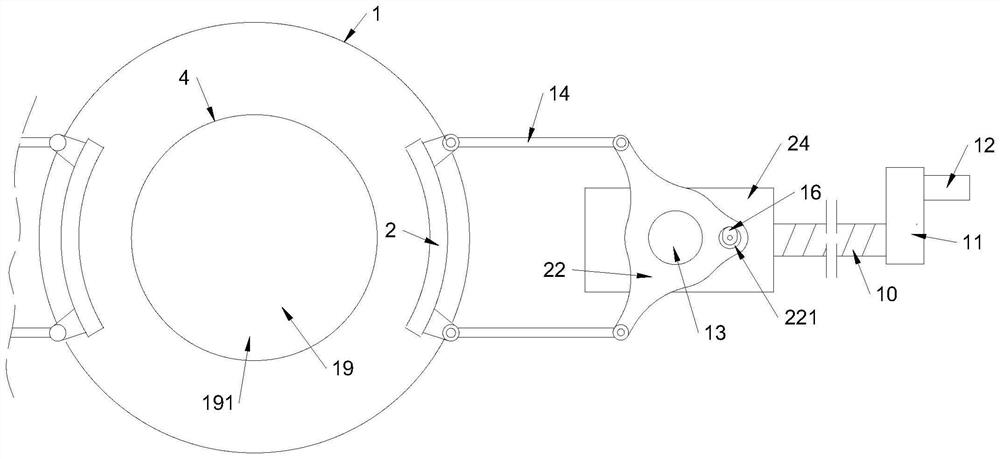

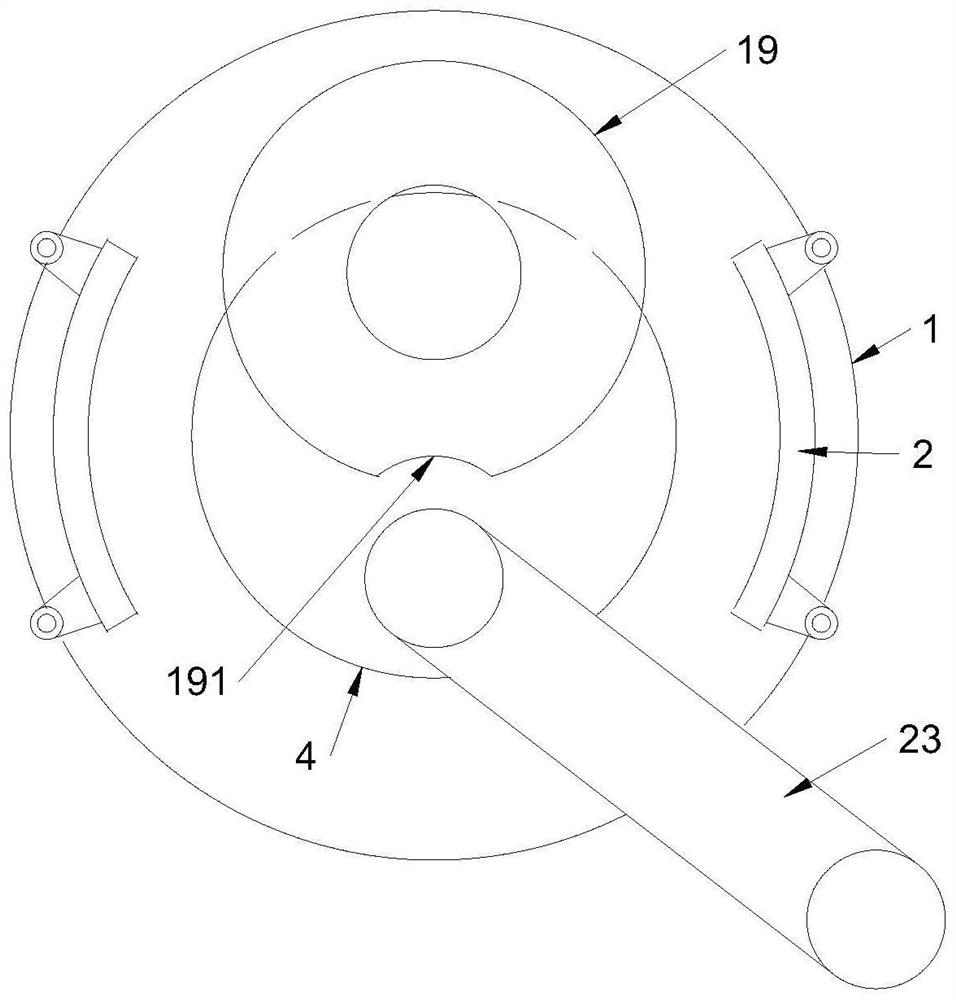

[0036] Next, combine Figure 1-3 A specific embodiment of the present invention is described in detail.

[0037] Reference attached Figure 1-2 , a rare earth molten salt electrolysis device based on anode adjustment and stable pole distance, including an electrolysis furnace 1 as a structural main body, the electrolysis furnace 1 has a built-in anode 2 and a cathode 3, the cathode 3 is suspended in the middle of the electrolysis furnace, and the cathode 3 is connected to the negative electrode of the power supply device, the cathode 3 is preferably made of high temperature resistant tungsten, molybdenum and other metal materials, the anode 2 is symmetrically arranged with respect to the cathode 3, the anode 2 is connected to the positive electrode of the power supply device, the anode 2 is made of graphite material, and the anode 2 , An electric field is formed between the cathodes 3, and the distance between them is the pole distance. The molten salt undergoes redox reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com