Device and method for sterilization and pH adjustment of circulating cooling water

A technology of circulating cooling water and driving devices, applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, water/sewage treatment, etc., can solve the problem of reducing conductivity and electrolysis efficiency, reducing use costs, and ineffective Good and other problems, to achieve the effect of high scraping efficiency, lower use cost, and good scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

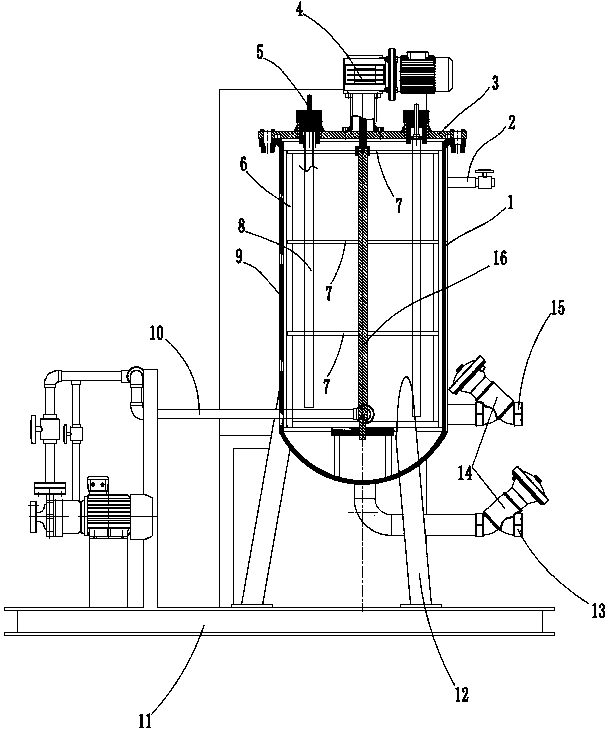

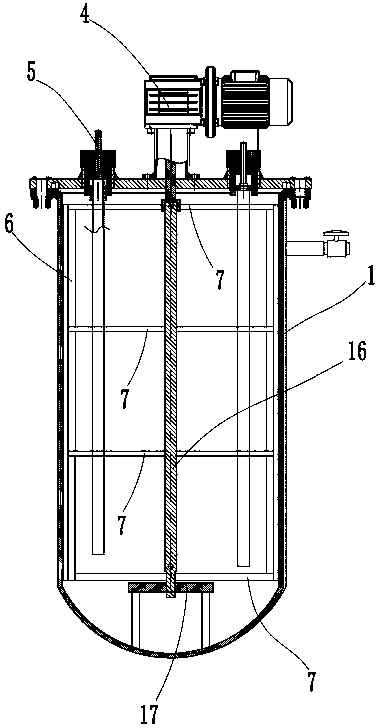

[0035] Such as figure 1 and figure 2 As shown, the device for circulating cooling water sterilization and pH adjustment in this embodiment includes an electrolytic reaction cylinder 1, and an electrode 5 is arranged in the electrolytic reaction cylinder 1. In this embodiment, an electrode 5 is connected to the electrolytic reaction cylinder Electrode rods in body 1, such as figure 1 As shown, two electrode rods are symmetrically arranged in the electrolytic reaction cylinder 1; the electrodes and the electrolytic reaction cylinder wall form an anode 8 and a cathode 9, and a scraper mechanism is also provided in the electrolytic reaction cylinder 1, and the scraper The scraper assembly of the mechanism is arranged corresponding to the wall of the electrolytic reaction cylinder, and when descaling is required, the scraper mechanism drives the scraper assembly to move on the wall of the electrolytic reaction cylinder.

[0036] In this embodiment, there is also a driving device...

Embodiment 2

[0039] Such as figure 1 and figure 2 As shown, the device for circulating cooling water sterilization and pH adjustment in this embodiment includes an electrolytic reaction cylinder 1, and an electrode 5 is arranged in the electrolytic reaction cylinder 1. In this embodiment, an electrode 5 is connected to the electrolytic reaction cylinder Electrode rods in body 1, such as figure 1 As shown, two electrode rods are symmetrically arranged in the electrolytic reaction cylinder 1; the electrodes and the electrolytic reaction cylinder wall form an anode 8 and a cathode 9, and a scraper mechanism is also provided in the electrolytic reaction cylinder 1, and the scraper The scraper assembly of the mechanism is arranged corresponding to the wall of the electrolytic reaction cylinder, and when descaling is required, the scraper mechanism drives the scraper assembly to move on the wall of the electrolytic reaction cylinder.

[0040] In this embodiment, a drive motor 4 is provided to...

Embodiment 3

[0042] Such as figure 1 and figure 2 As shown, according to the device for circulating cooling water sterilization and pH adjustment described in Embodiment 1 or Embodiment 2, the scraper mechanism of this embodiment includes a scraper drive shaft 16, and the scraper drive shaft 16 is connected to the driving device, and the scraper drives The other end of the shaft 16 extends into the electrolytic reaction cylinder 1 , and the scraper assembly is connected to the scraping drive shaft 16 . The driving device drives the scraper drive shaft to rotate, and then drives the scraper assembly to move to realize the scraping operation.

[0043] In this embodiment, the scraper assembly is a cylindrical structure compatible with the electrolytic reaction cylinder 1 , and a support rib 7 for connecting with the scraper drive shaft is provided inside the scraper assembly. The scraper assembly with a cylindrical structure is conducive to the rapid scraping operation of the electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com