Steel dam gate convenient to install

A technology that is easy to install and steel dams, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of difficult accurate positioning, difficult sealing, difficult operation, etc., to reduce the installation workload, easy to seal, reliable use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

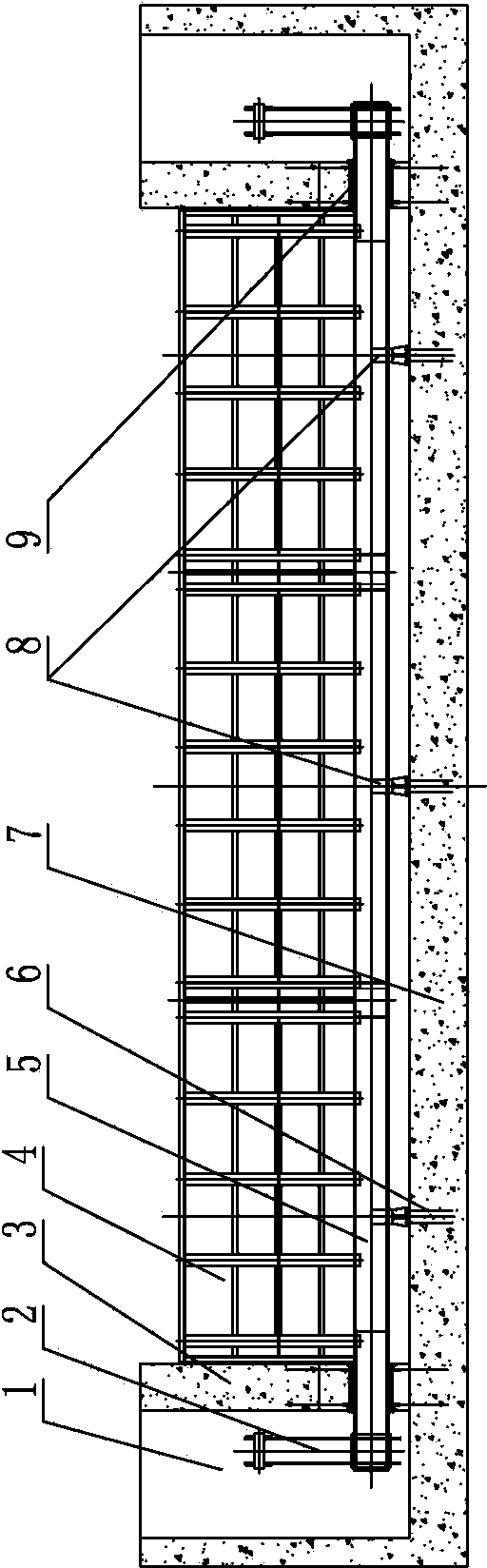

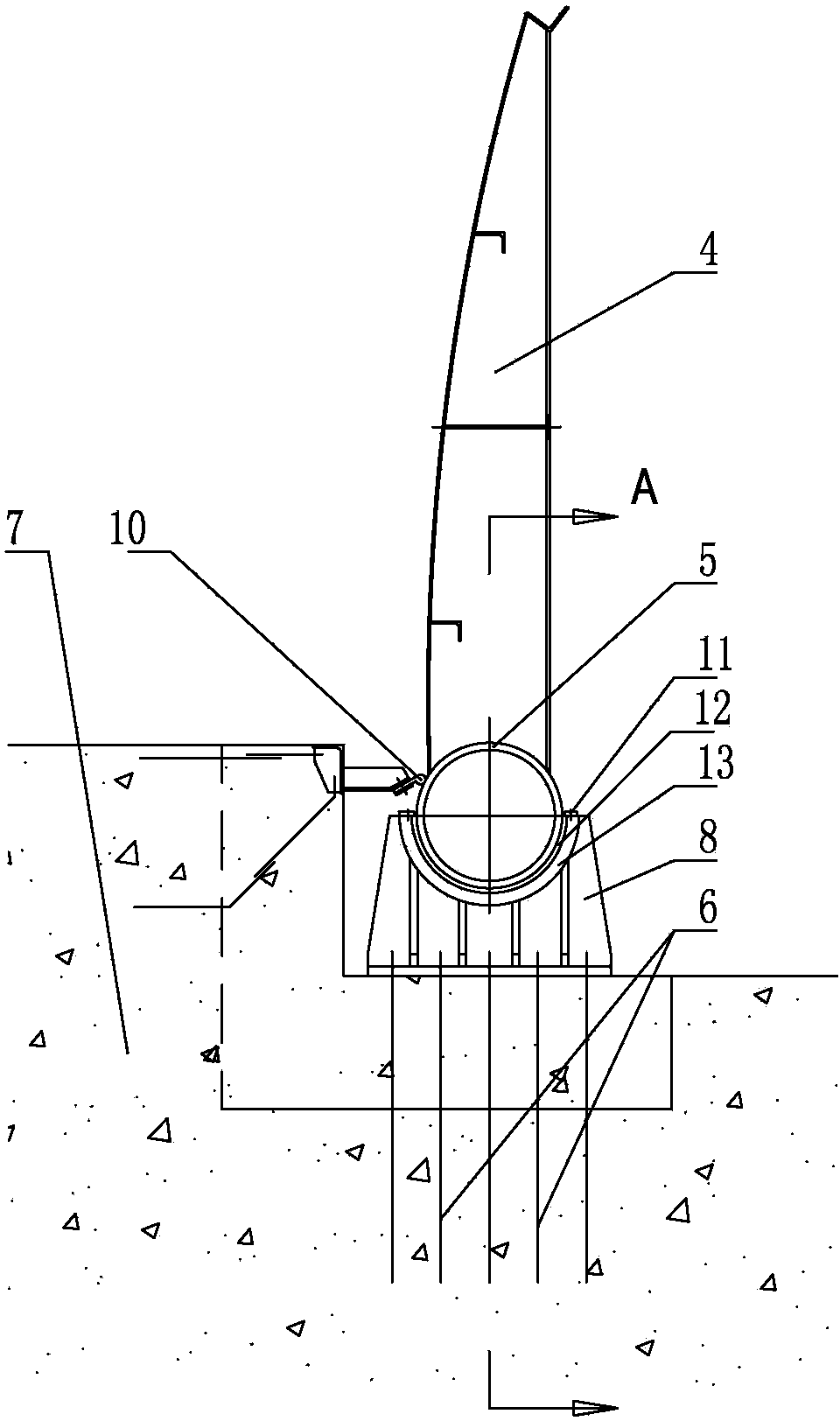

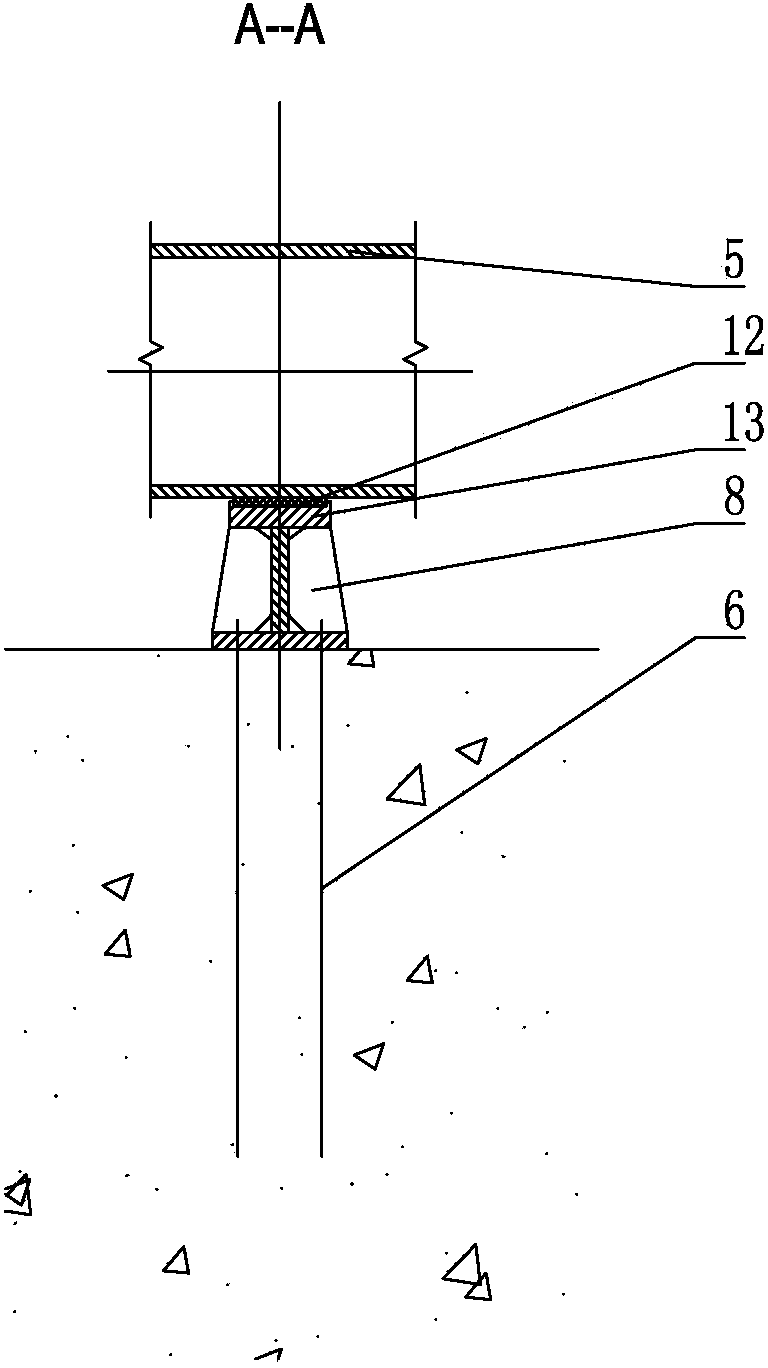

[0017] Such as Figure 1-3 As shown, it is a steel dam gate that is easy to install, including a bottom shaft 5, which is arranged across the river, walls 3 are arranged on both sides of the river, and a concrete foundation 7 is arranged at the bottom of the river. When the concrete foundation 7 is constructed, Embedded parts 6 are embedded in the corresponding positions, and the embedded parts 6 are used to install fixed hinge seats 8; the bottom shaft 5 is supported on multiple hinge seats 8 fixedly arranged at the bottom of the river, and the two ends of the bottom shaft 5 pass through the wall 3 It extends into the hoist room 1, where a hoist is installed, the end of the bottom shaft 5 is connected to the hoist through the crank arm 2, and the door leaf 4 for water blocking is connected to the bottom shaft 5; the bottom shaft 5 and the wall 3 are connected through a sealing support 9; each hinge seat 8 has an arc section 13, and the arc section 13 is equipped with a wear-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com