Deformation prediction method of cold stamping head based on deformation-induced martensitic transformation

A martensitic phase and prediction method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that it is difficult to reflect the deformation of the head and the large difference in results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment the present invention is described in further detail:

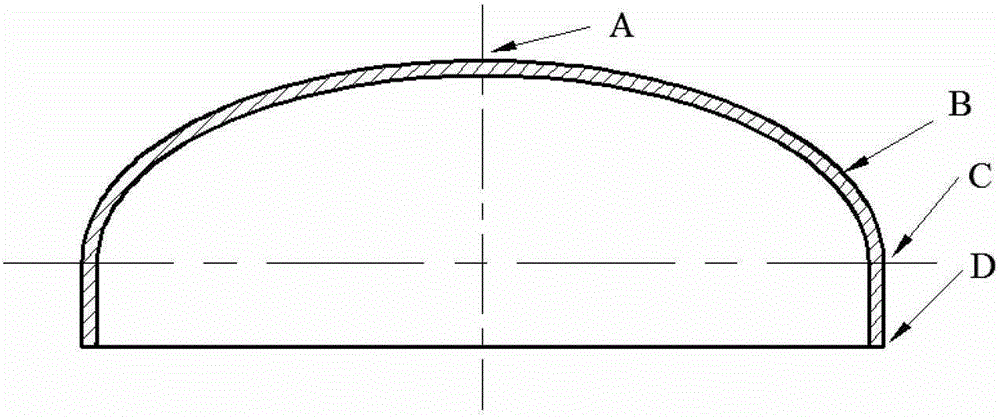

[0024] like figure 1 As shown, according to the different stress conditions of different areas of the cold stamping head during the stamping forming process, the cold stamping head is divided into two parts: the shell part of the A-B section, the transition of the B-D section and the straight edge section; among them, B-C Segments are transitional segments and segments C-D are straight edge segments.

[0025] The deformation prediction method based on the deformation-induced martensitic transformation of the cold stamping head includes the following specific steps:

[0026] Step A: Carry out the cold stamping forming test of the head and the finite element simulation of the cold stamping process.

[0027] The method of the cold stamping forming test of the head is as follows: firstly, on the steel plate for making the cold stamped head, the measuring points are drawn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com