Patents

Literature

33results about How to "Quickly and accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

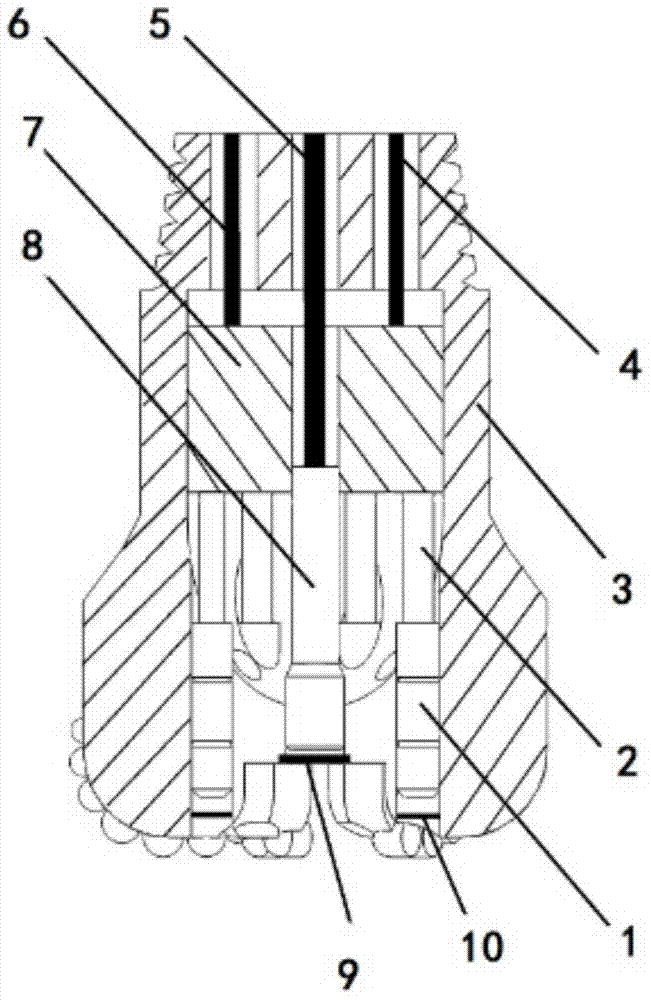

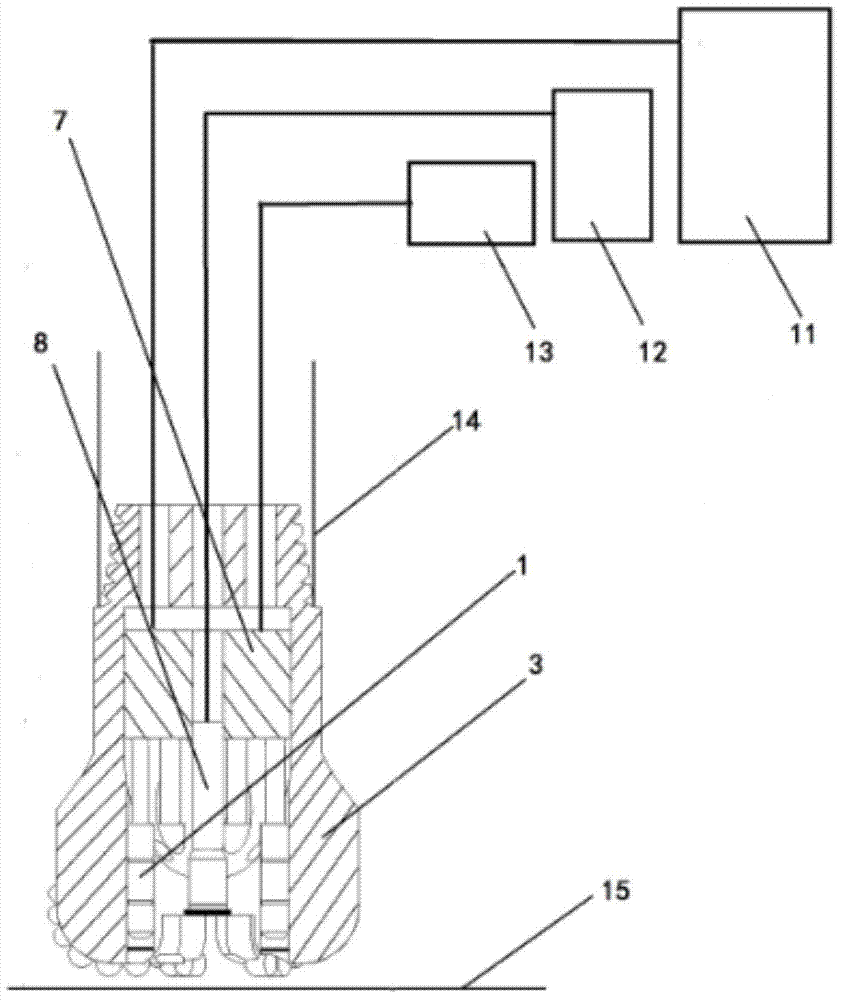

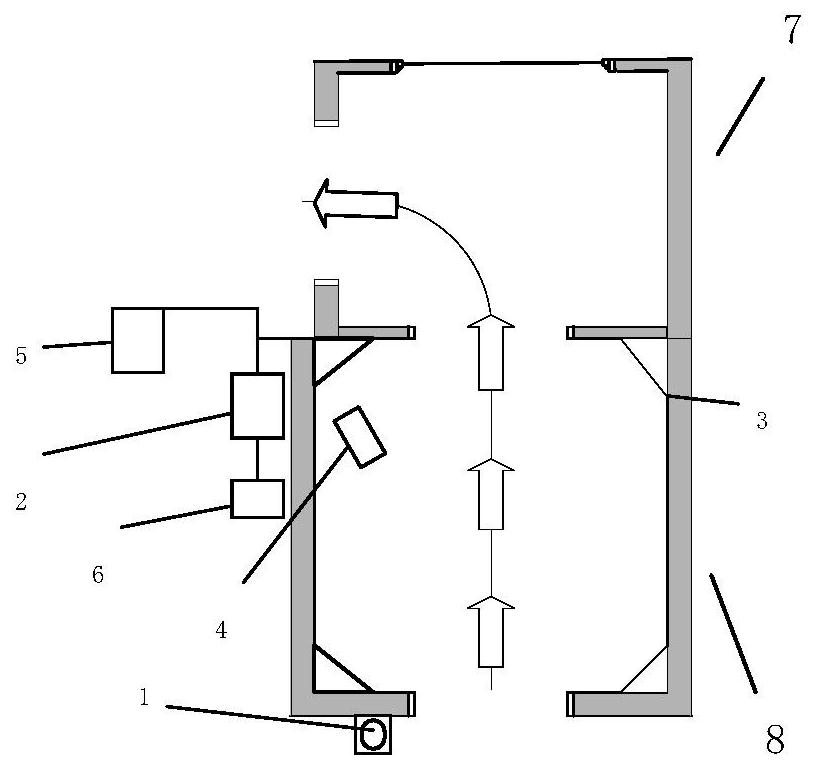

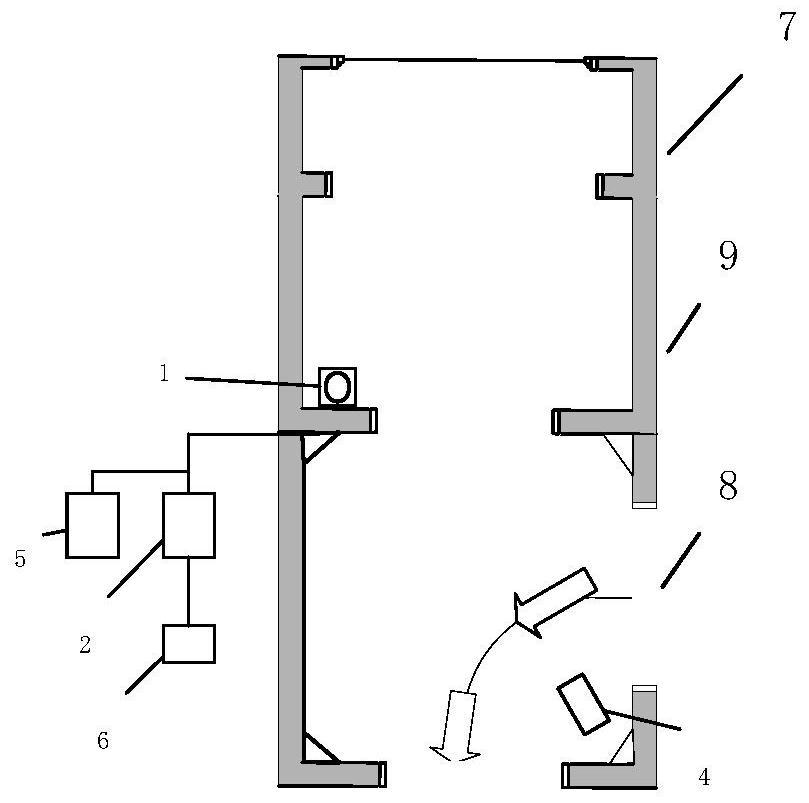

Laser drill, laser drilling tool and well drilling rock breaking method

The invention provides a laser drill, a laser drilling tool and a well drilling rock breaking method. The laser drill comprises a drill body (3); a camera (8) and a plurality of laser heads (1) are contained in the drill body (3); an adjusting bracket (7) capable of moving the camera (8) and / or the laser heads (1) is also contained in the drill body (3); through holes corresponding to the camera (8) and the laser heads (1) are formed in the head part of the drill body (3). The laser drilling tool containing the laser drill is provided with an underground night vision system and an aboveground control system; by the drilling rock breaking method, the problems that the hard rock stratum drilling and production efficiency is low, real-time observation cannot be performed underground, and the like are solved, the rock breaking efficiency is greatly increased, the loss of the drilling tool is reduced, and the cost is reduced.

Owner:PETROCHINA CO LTD

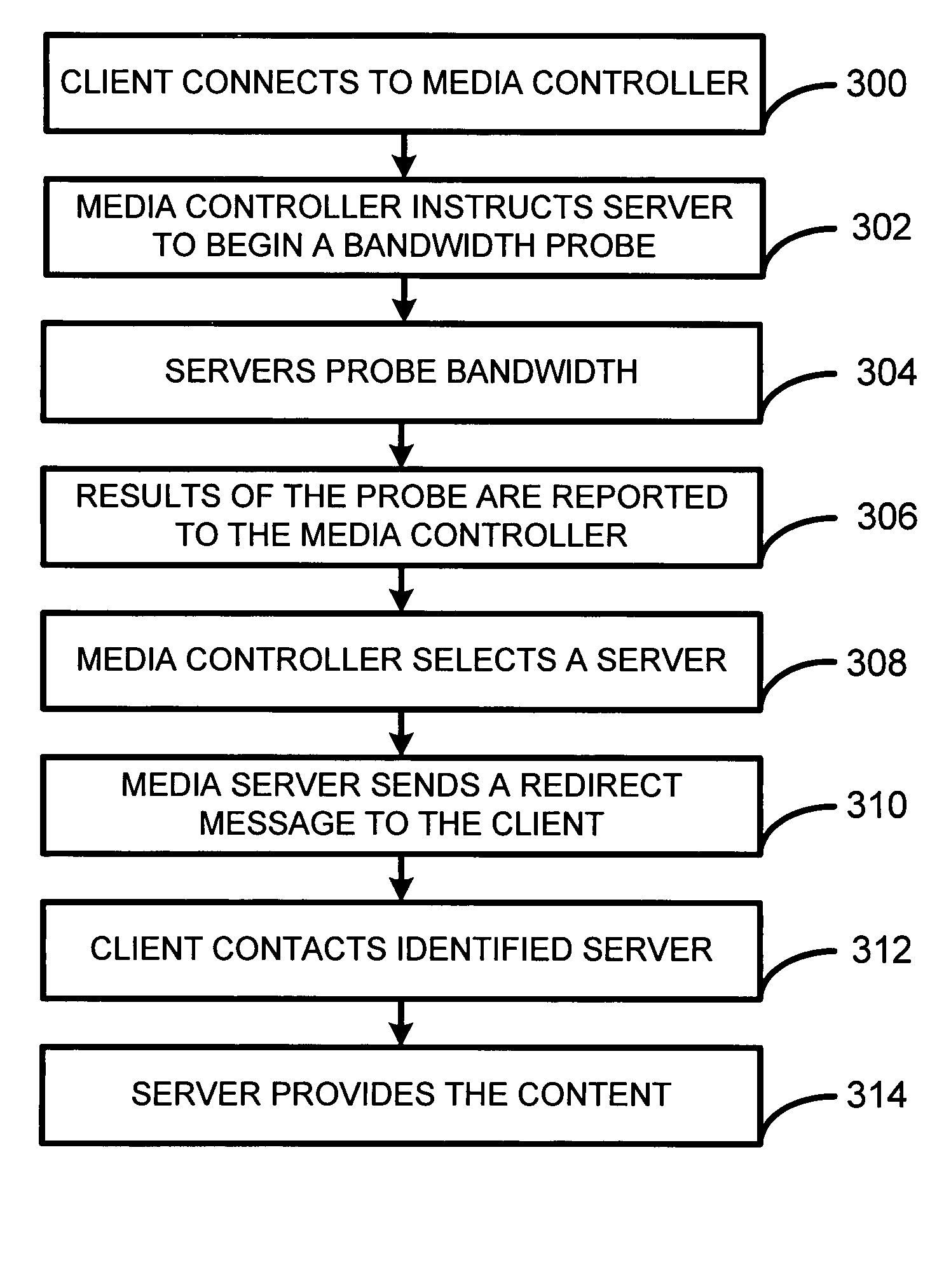

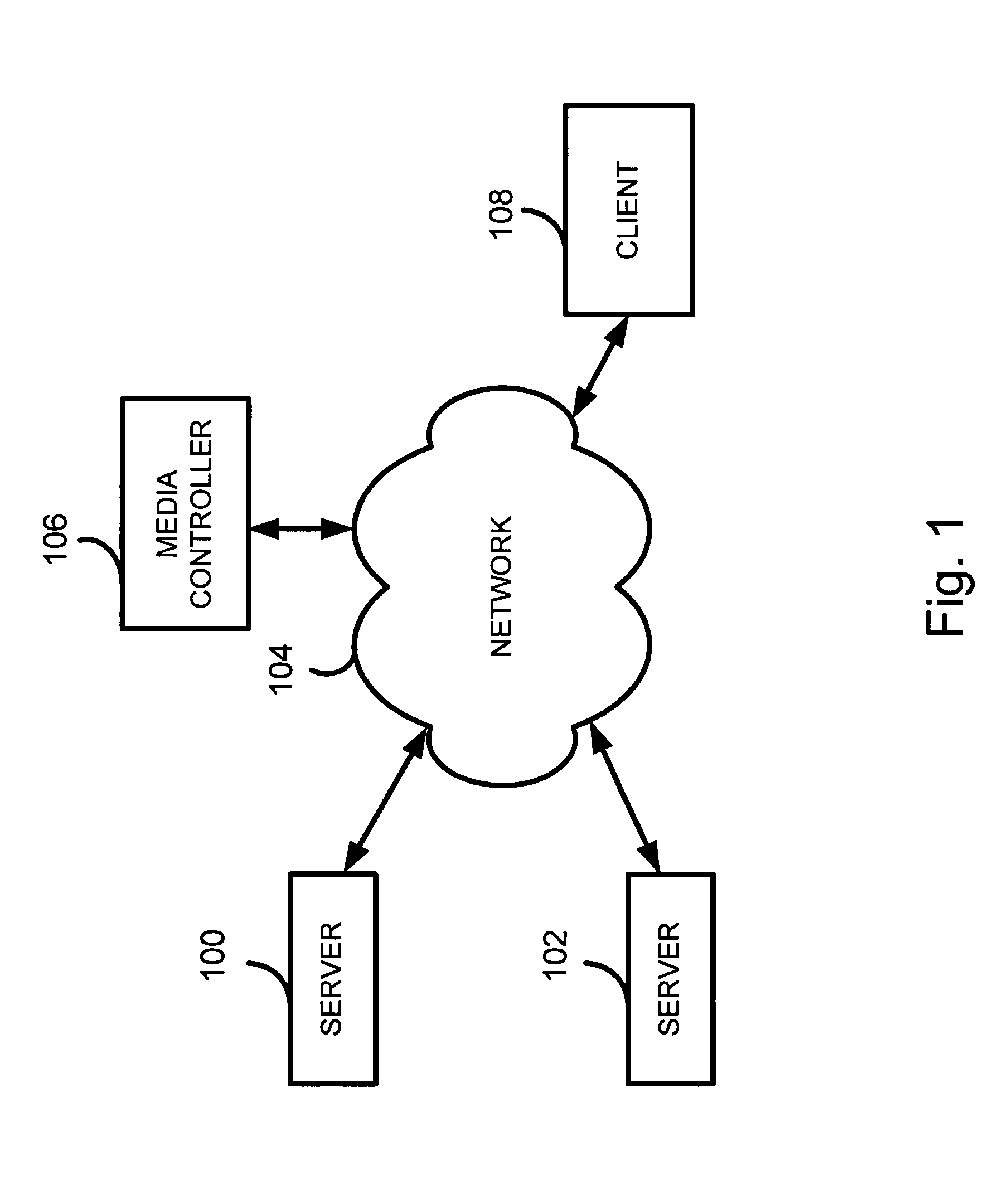

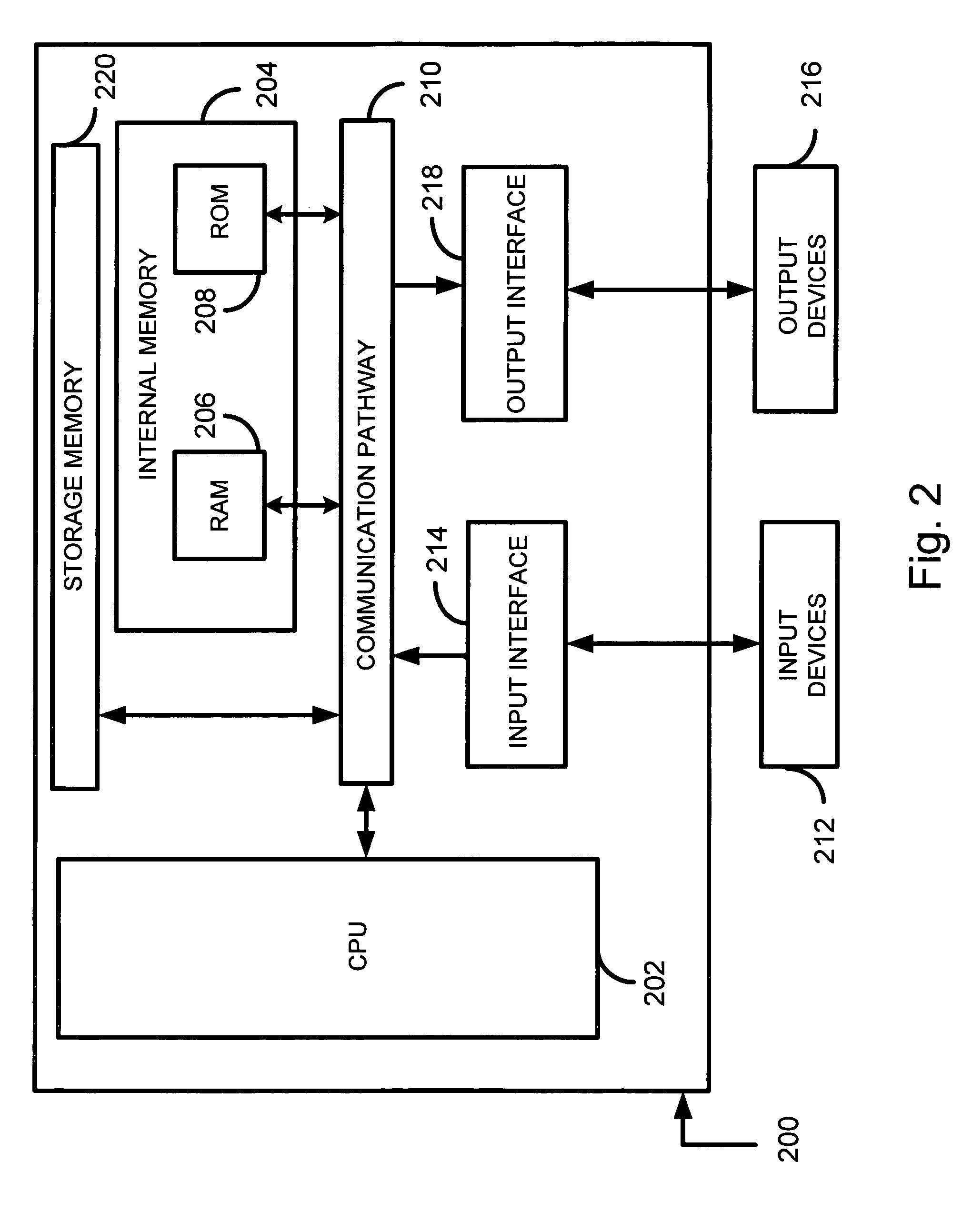

Method for redirection of web streaming clients using lightweight available bandwidth measurement

ActiveUS20050165931A1Quickly and accuratelyThe process is fast and accurateMultiple digital computer combinationsSecuring communicationClient-sideDistributed computing

In accordance with the teachings of the present invention, a method for selecting a server to provide content to a client is presented. A media controller receives a request from a client for content. The media controller instructs a plurality of servers each storing the content required by the client to perform a bandwidth measurement referred to in the disclosure as a bandwidth probe. The result of the bandwidth probe is communicated to the media controller. The media controller selects a server (i.e., an identified server) for communication with the client based on the result and communicates the selection in the form of a redirect command to the client. The client then communicates directly with the identified server.

Owner:AT&T INTPROP I L P

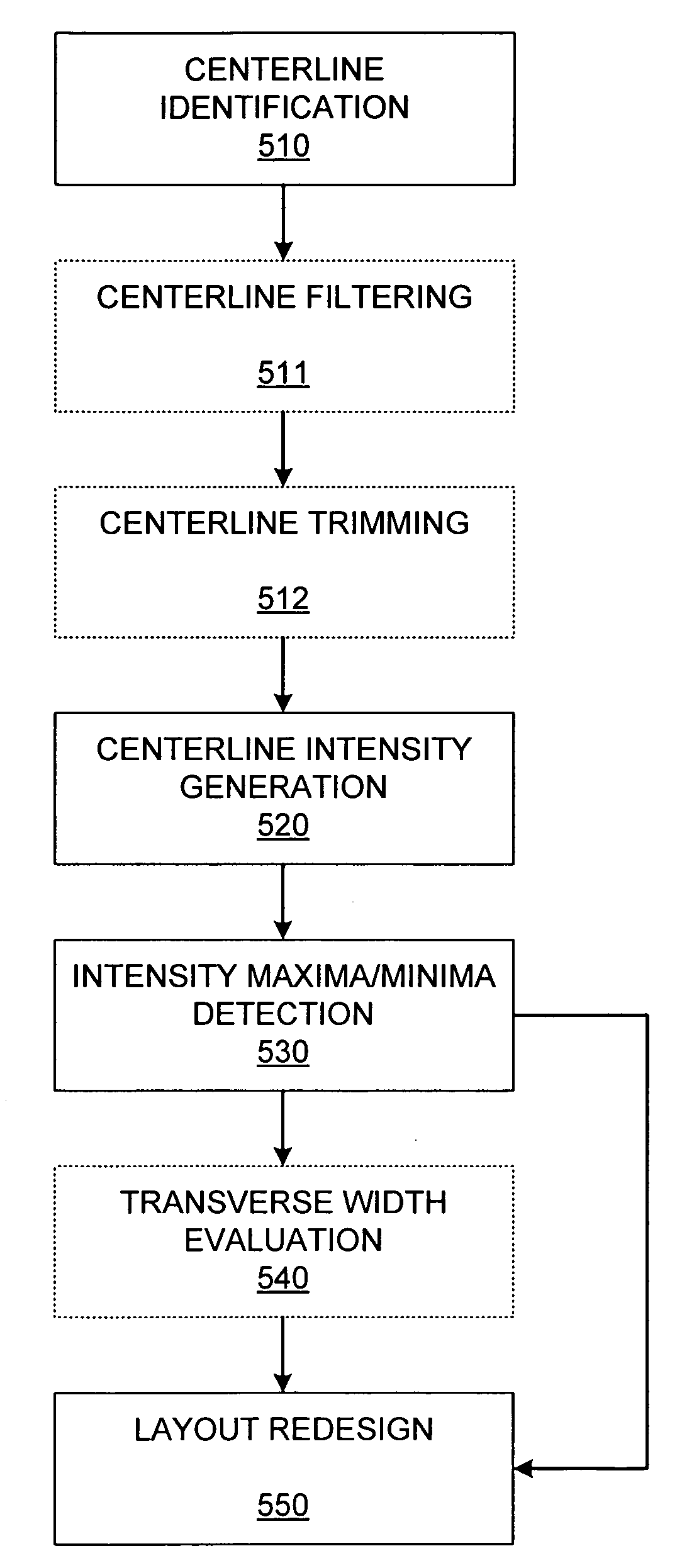

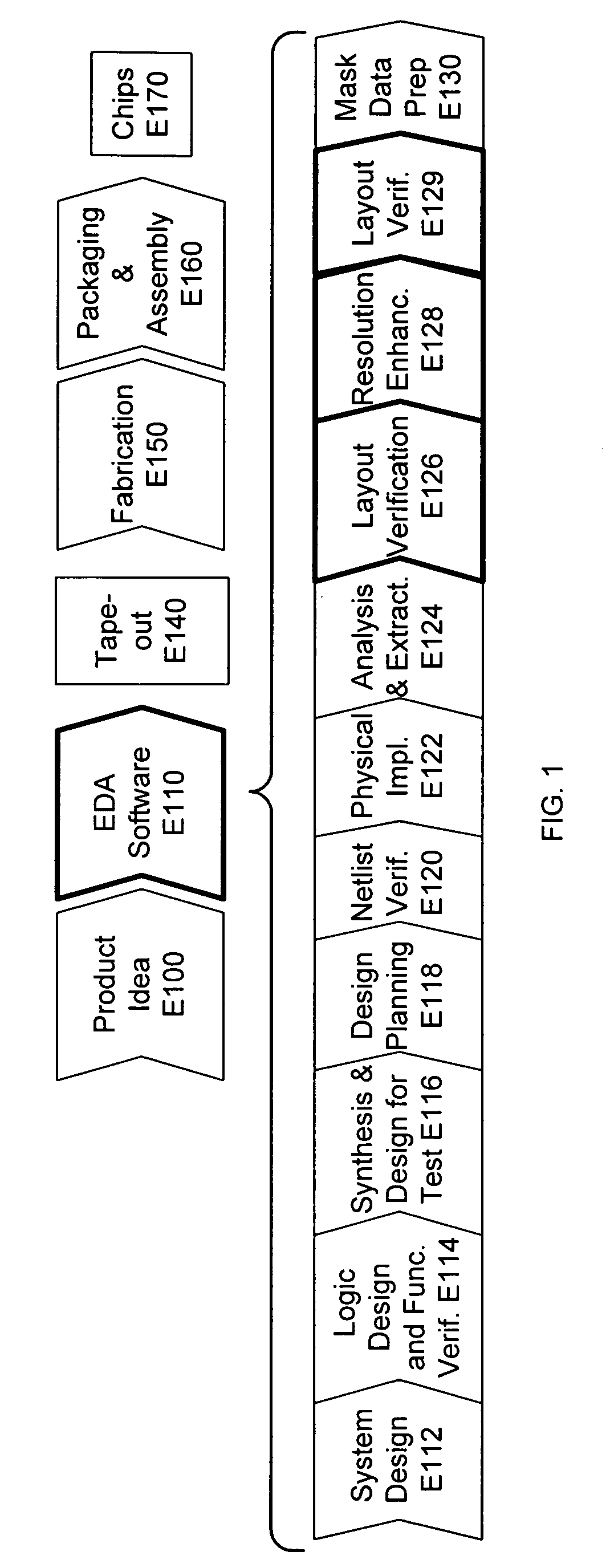

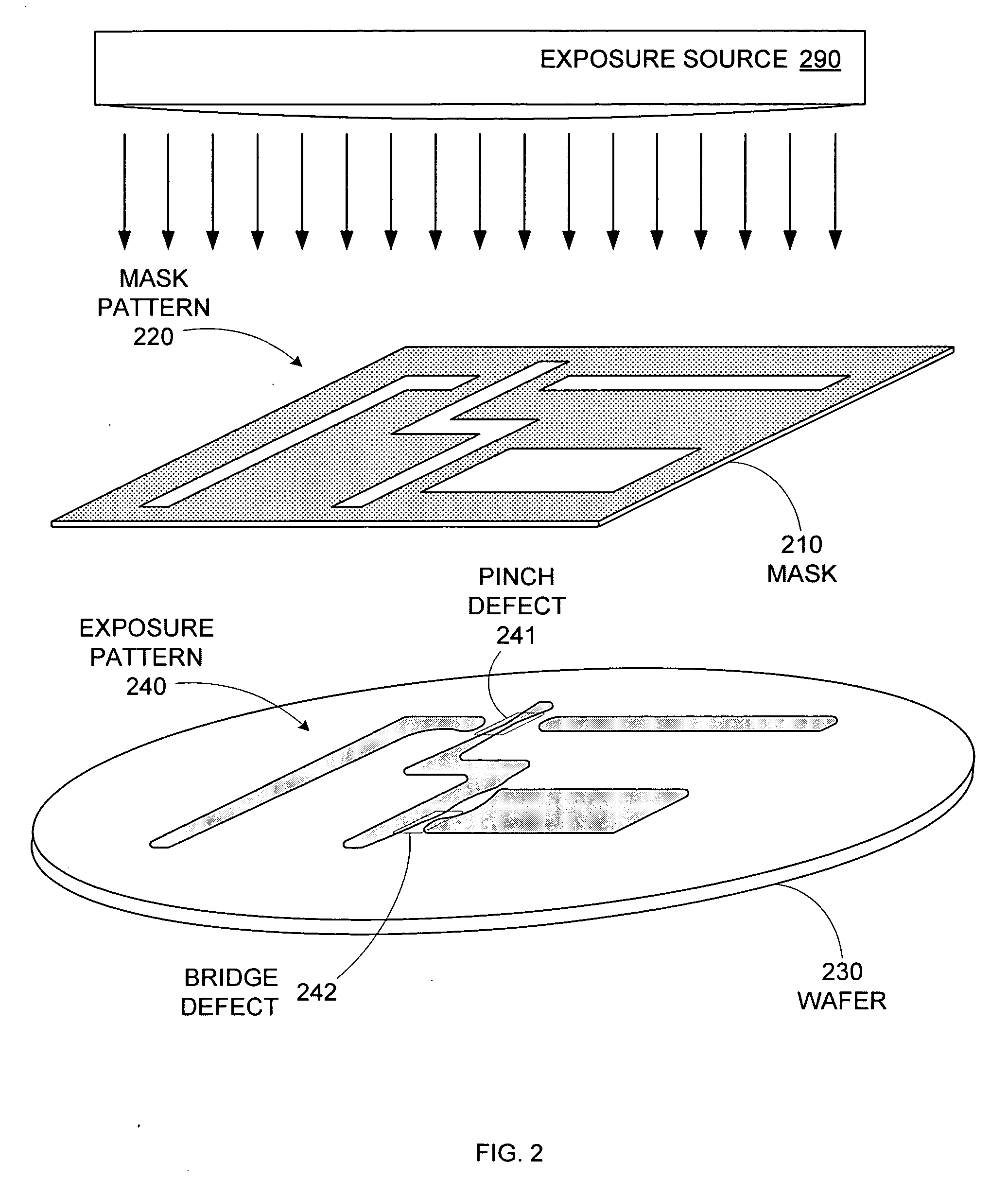

Centerline-based pinch/bridge detection

ActiveUS20060271906A1Low computational costQuickly and accuratelyOriginals for photomechanical treatmentSpecial data processing applicationsEngineeringLithography

A method for performing layout verification involves identifying feature centerlines in a mask layout, and then performing lithography simulation along the centerlines to generate a set of intensity distributions. At each local maxima or minima in the intensity distributions, further lithography simulation can be performed to determine an exposure pattern width at those local maxima / minima (check positions). The exposure pattern widths can then be evaluated to determine whether an actual pinch or bridge defect will be generated at those locations. If defect generation is likely (based on the lithographical simulation) at a particular location, the corresponding portion of the mask layout can be redesigned to avoid defect generation during actual production. In this method, accurate layout verification can be performed with a minimum of time-consuming lithography modeling.

Owner:SYNOPSYS INC

Systems and Methods of Using Labels for Evaluation of Produce and Other Foods

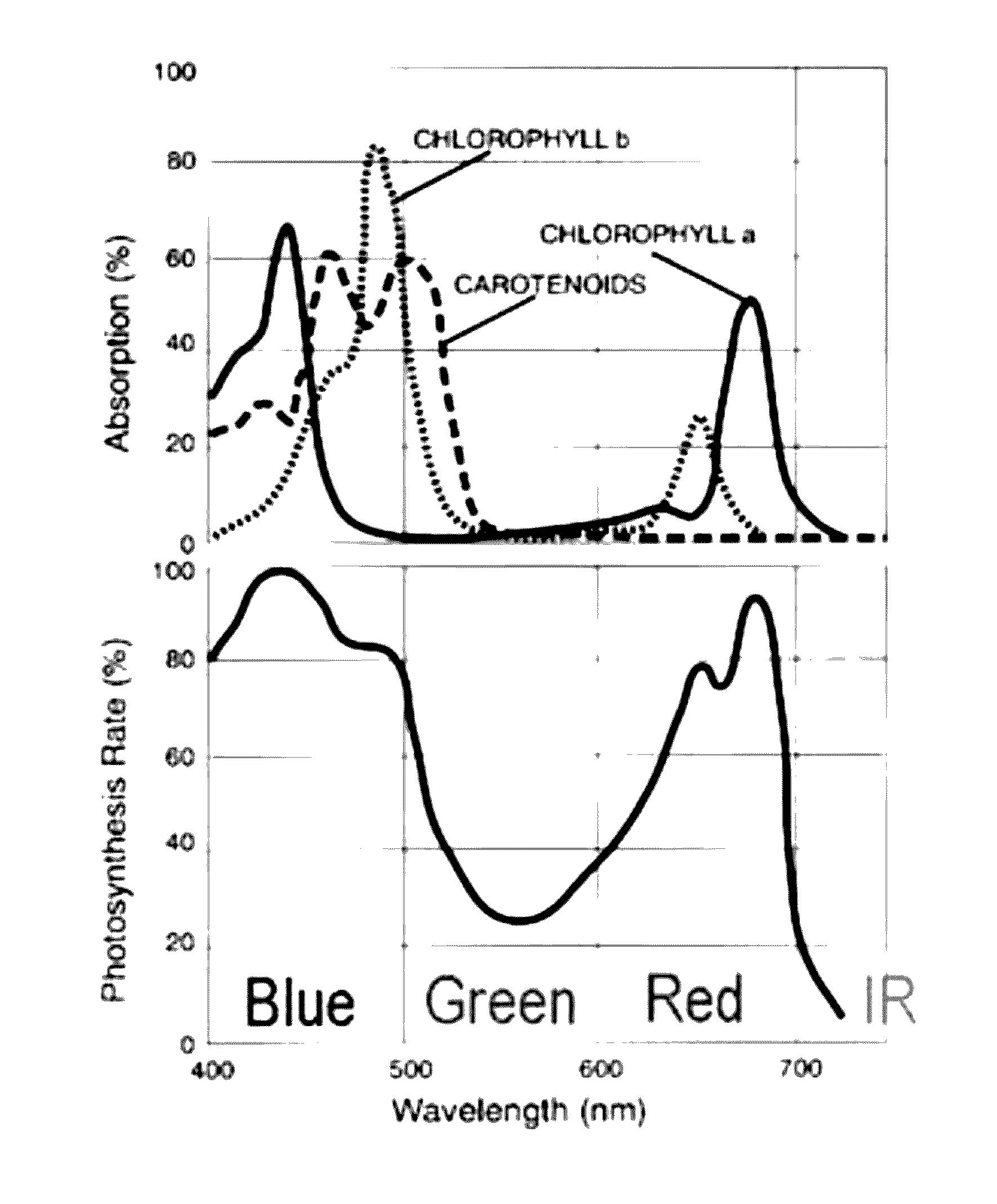

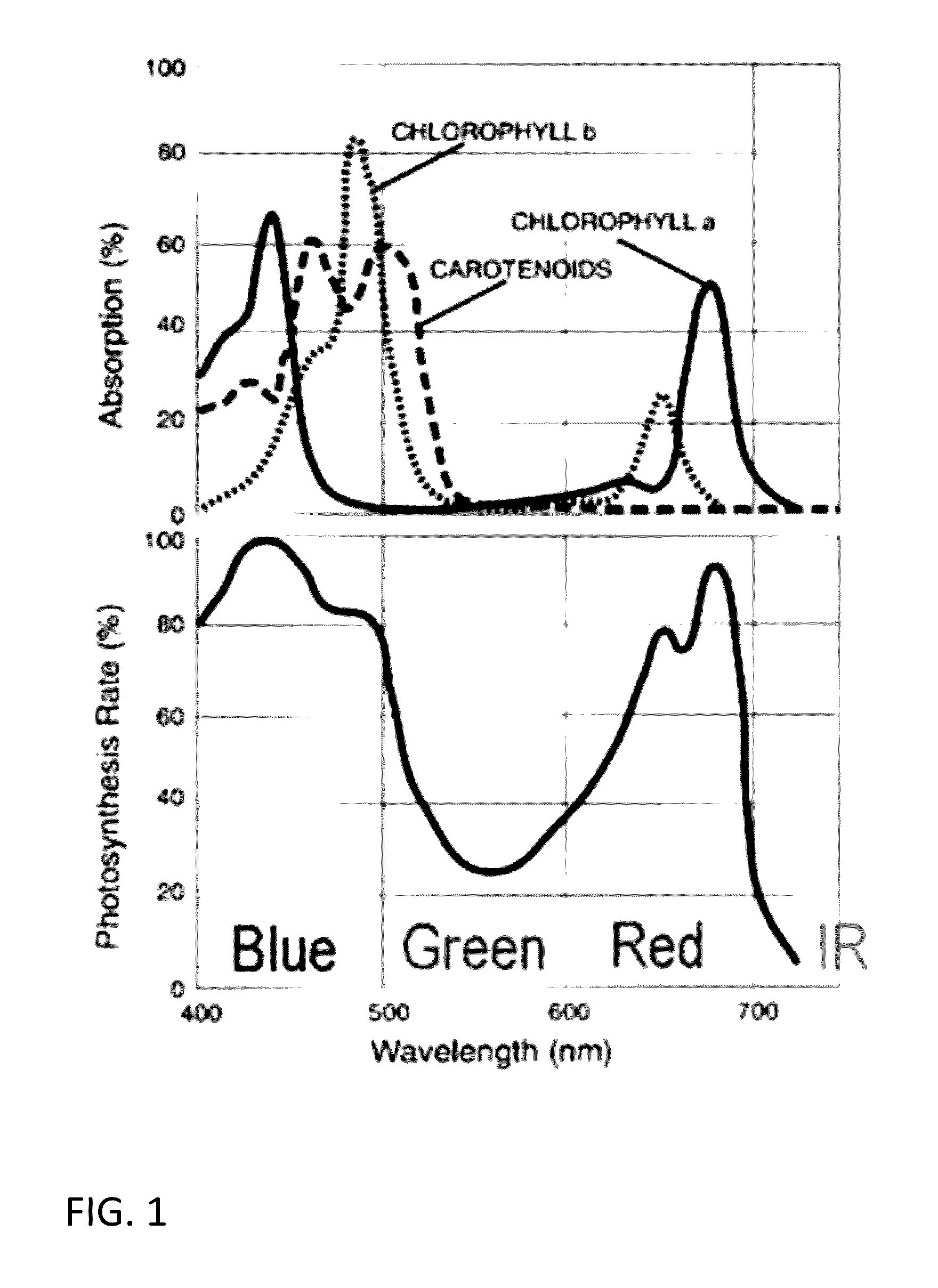

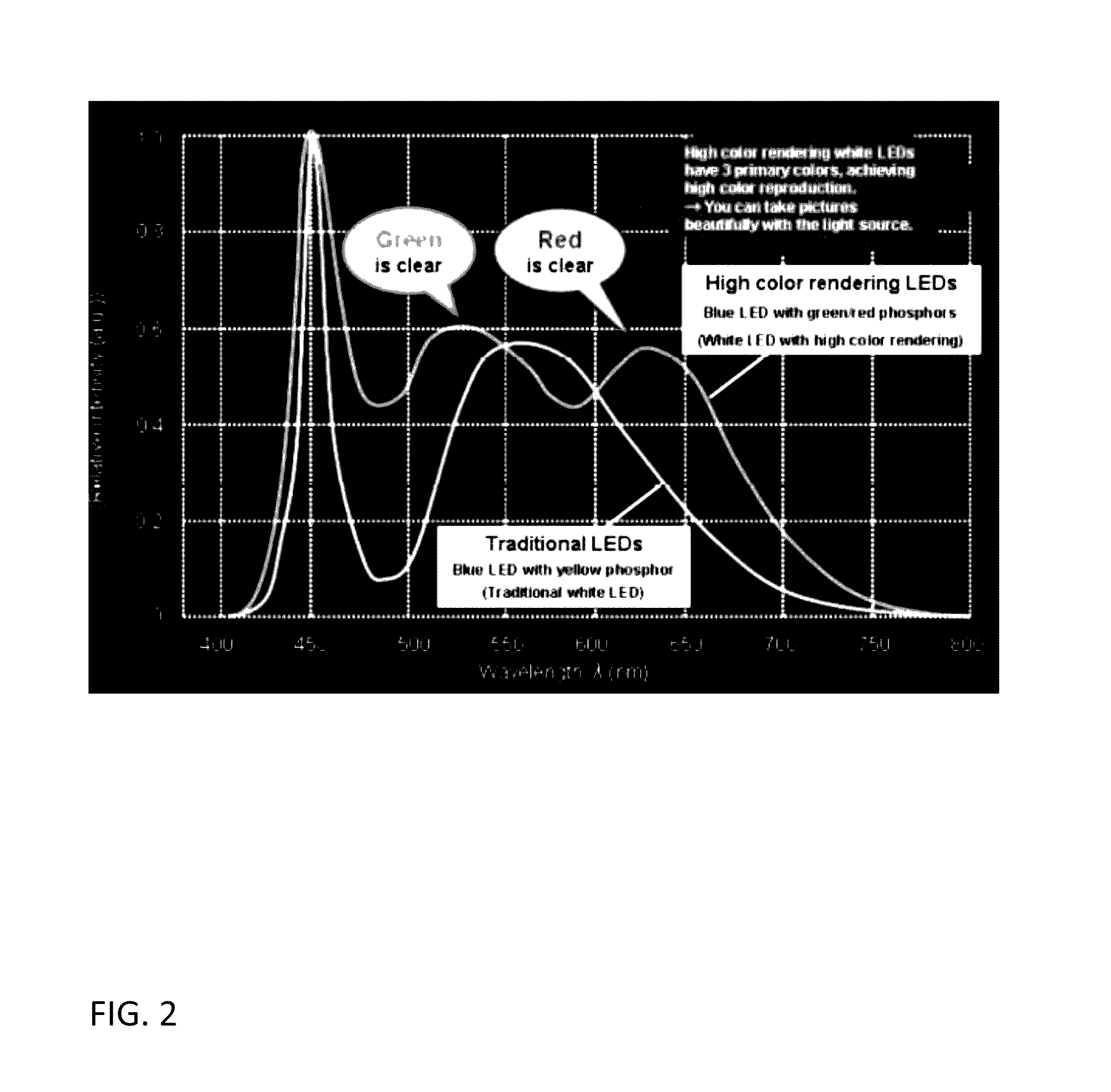

InactiveUS20160307040A1Quickly and accuratelyOvercomes shortfallImage enhancementImage analysisBiological productWideband

Attributes of vegetables or biologics are derived by use of color imaging sensors and relative spectral band analysis. Enabled smart phones or dedicated single pixel or focal plane instruments for crop applications to quickly report the biological condition of vegetables or other organics by providing an augmented view or relative quantification of RGB ratios of the inspected items. The RGB ratios are compared to RGB ratios of preprinted labels. The comparison yields information regarding the freshness and other attributes of the inspected item. Disclosed embodiments are well suited for analyzing the health and needs of living plants or crops. Ratios of observed wide band red, green and blue are compared on a relative basis. While food shopping, an enabled smart phone may view an agricultural product and use a preprinted RGB ratio label as a reference guide.

Owner:APPLICOLOR INC

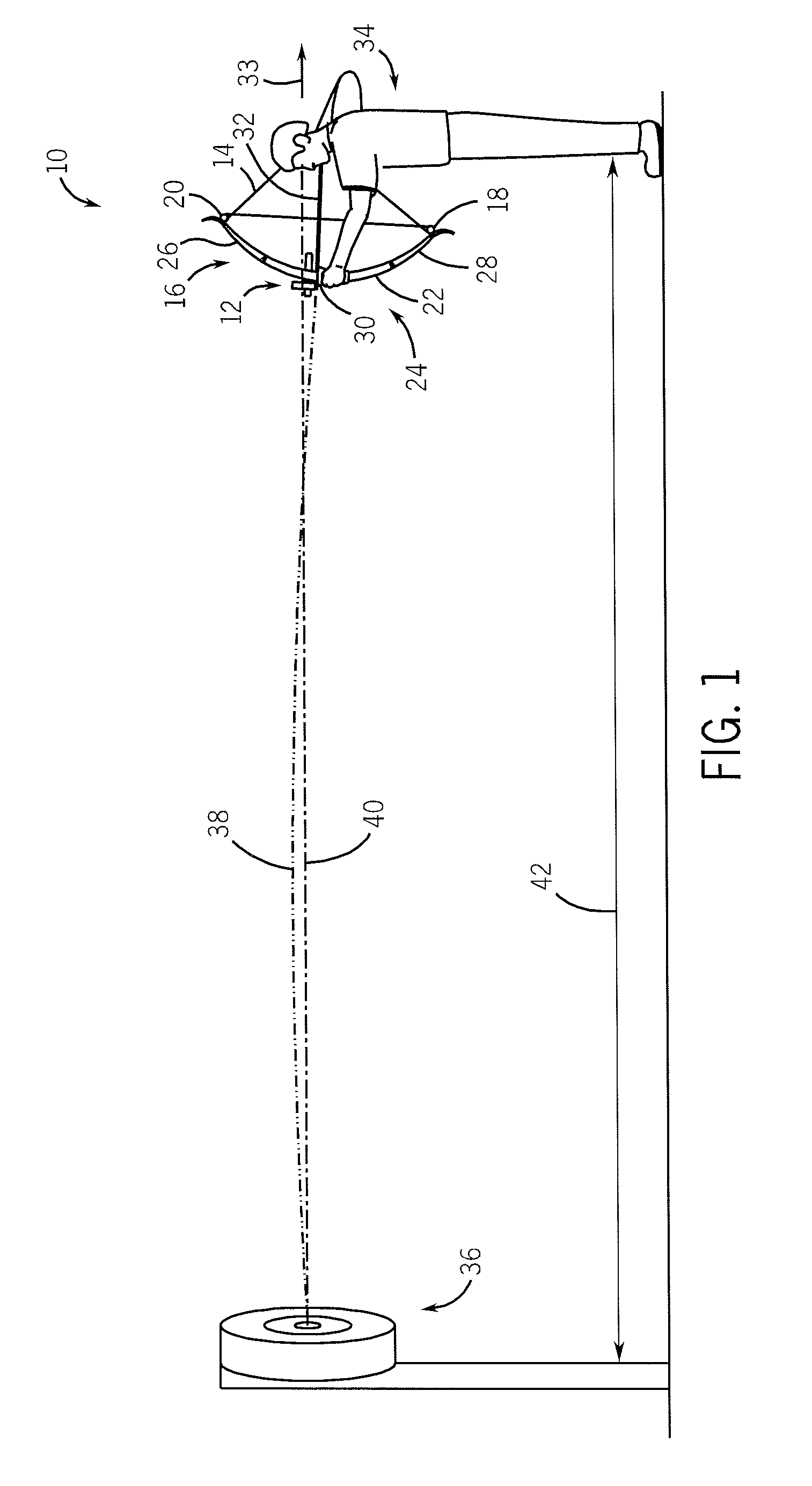

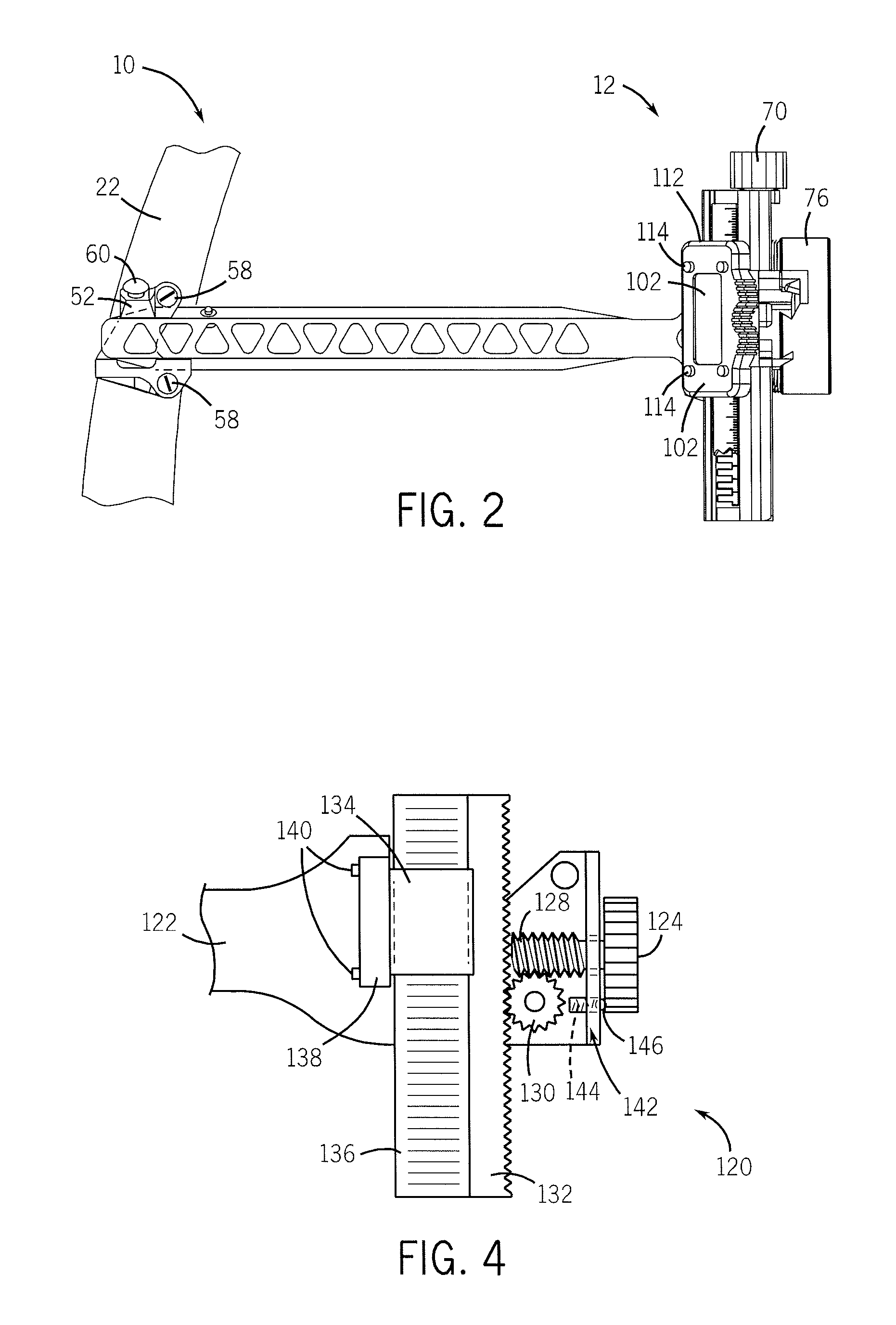

Digital archery sight

InactiveUS20080289201A1Quickly and accuratelyAccurate and repeatableBows/crossbowsSighting devicesStatorEngineering

A bow sight that includes a body, a stator, a slide, and an electronic sight position indicator. The body is constructed to secure the sight to a bow and the stator and slide are attached to the body such as to allow relative motion between the stator and the slide. The position indicator is attached to the bow sight and electronically determines the relative position of the stator and the slide and thereby provides an indication of an orientation of an eyepiece relative to the bow.

Owner:SUPERIOR DESIGN

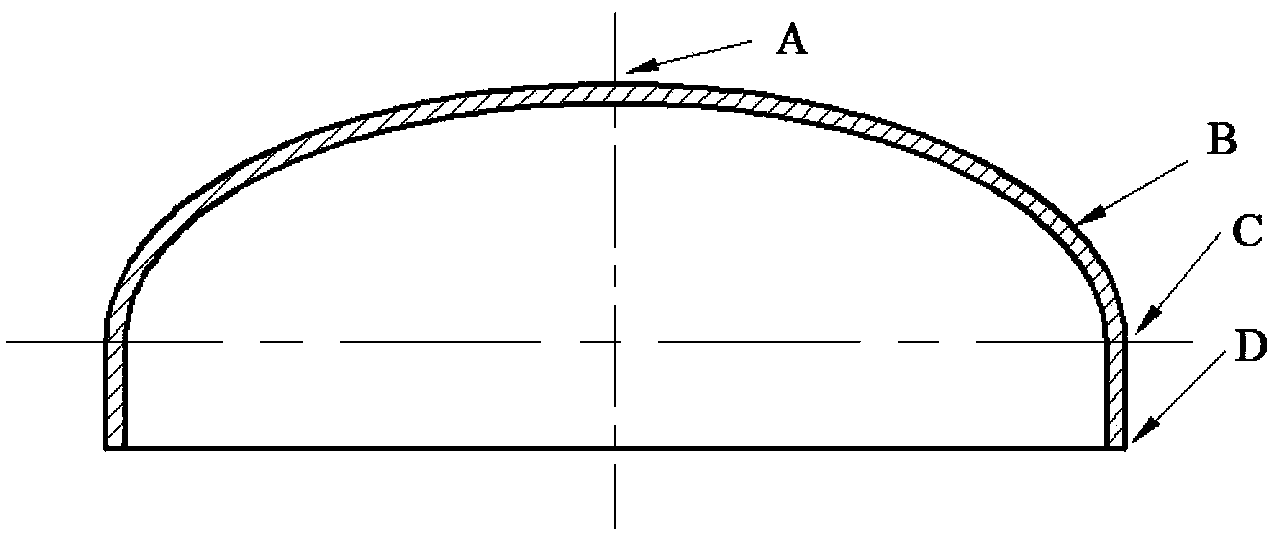

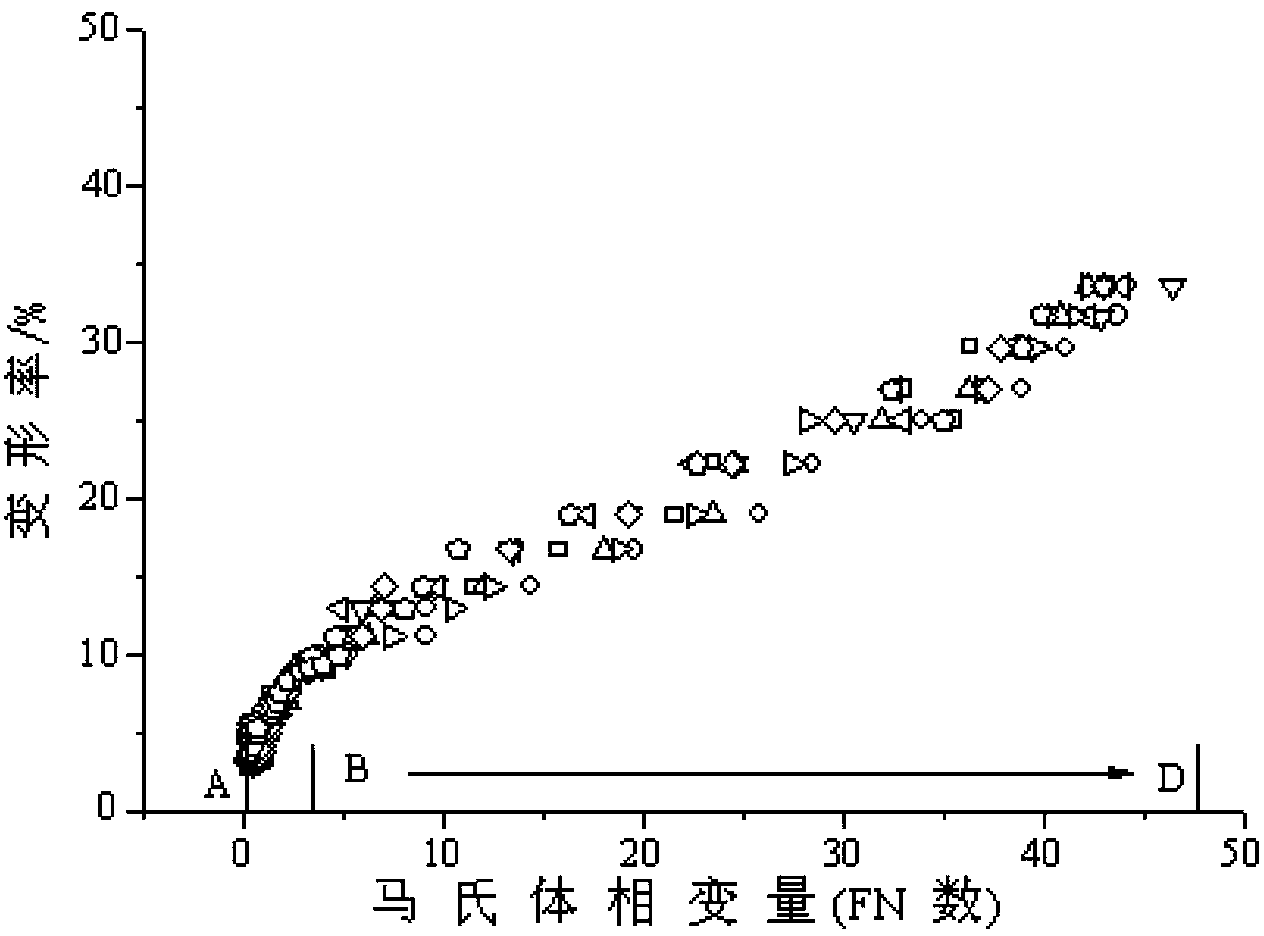

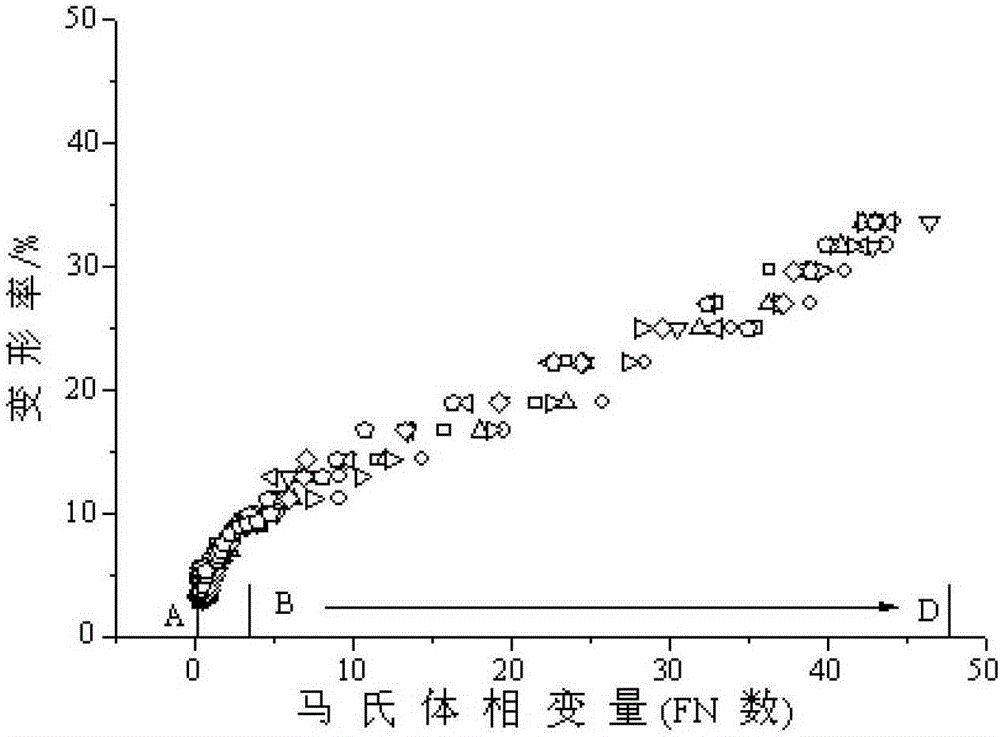

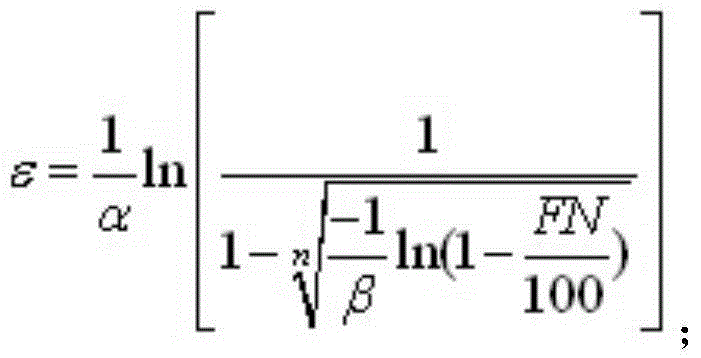

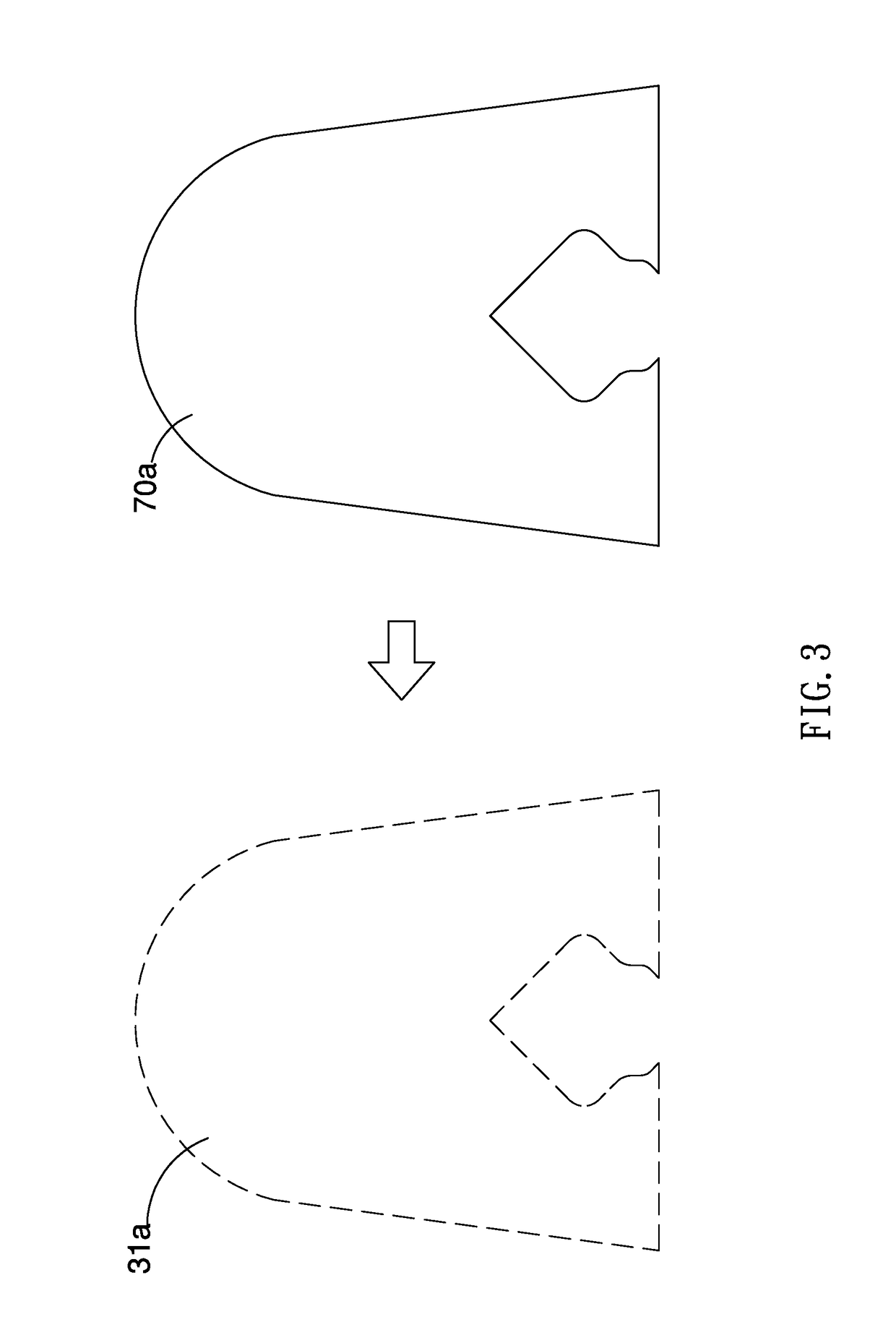

Cold pressing head deformation quantity predicating method based on deformation-induced martensite phase transformation

ActiveCN103353296AEasy to knowQuickly and accuratelyMeasurement devicesMartensite transformationMeasuring instrument

The invention relates to quality detection techniques used for heads molded through cold pressing and aims to provide a cold pressing head deformation quantity predicating method based on deformation-induced martensite phase transformation. The deformation quantity predicating method includes specific steps of conducting a head cold pressing molding test, performing finite element simulation in a cold pressing process and creating a relation curve of the deformation quantities and the martensite phase transformation quantities of the cold pressing head; using a ferrite measuring instrument for measuring martensite phase transformation quantities of areas of the cold pressing head requiring predication respectively; and substituting the measured martensite phase transformation quantities of the different areas of the cold pressing head into the obtained relation curve of the deformation quantities and the martensite phase transformation quantities of the corresponding areas respectively, so that the deformation quantities of the areas of the cold pressing head are obtained. By adopting the deformation quantity predicating method provided by the invention, curves of the deformation quantities of transition segments, straight sections and shell parts of different austenitic stainless steel heads can be determined and the plastic deformation quantities of the heads can be obtained conveniently, quickly and accurately by using the ferrite measuring instrument. The deformation quantity predicating method is very suitable for applying to the field of engineering.

Owner:ZHEJIANG UNIV

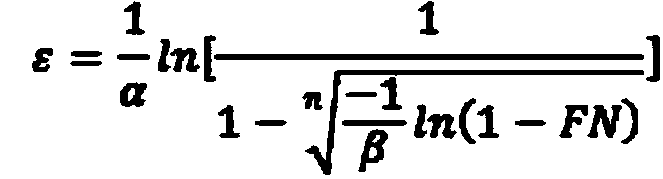

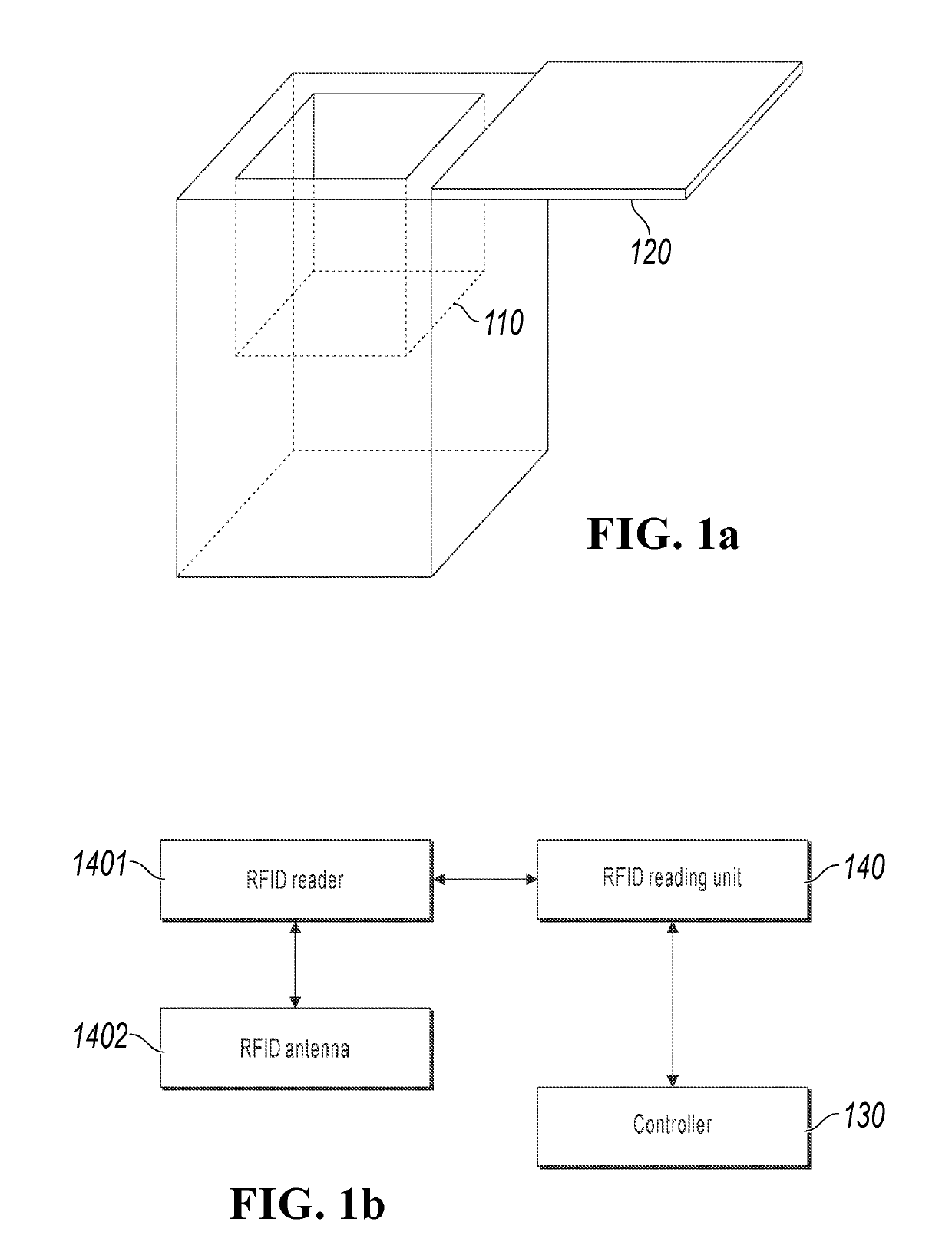

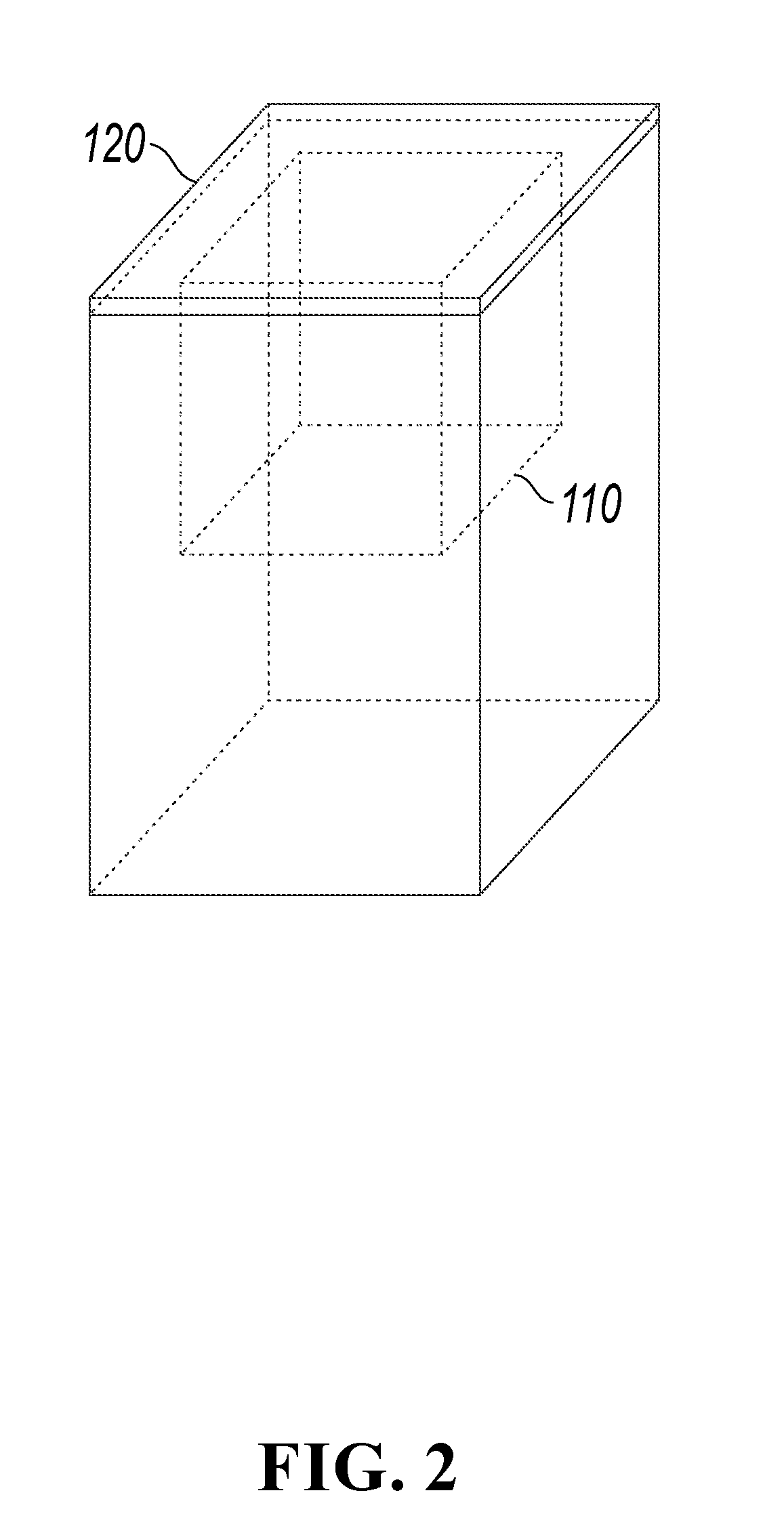

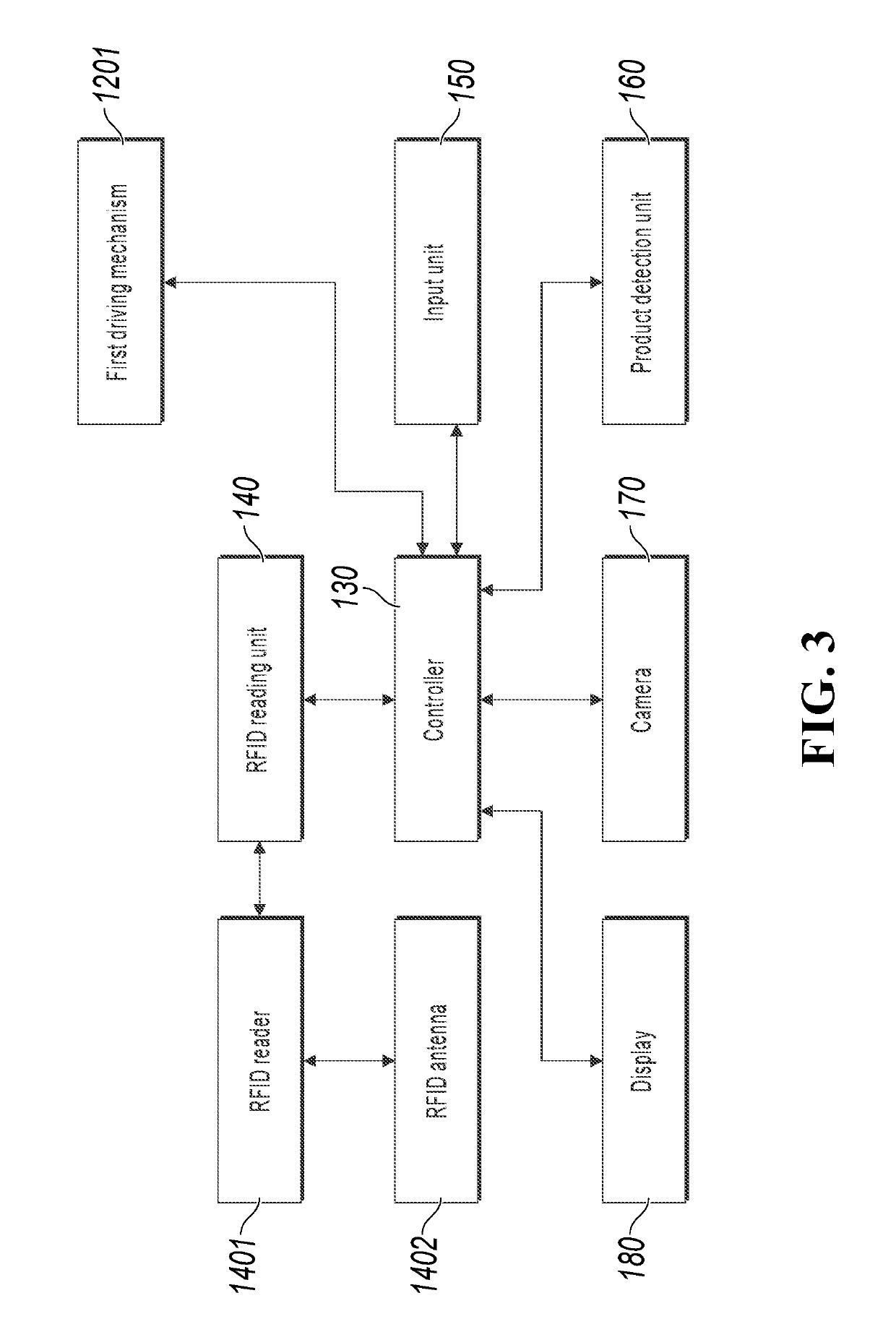

Self-service payment device and control method thereof

ActiveUS20190172296A1Quickly and accuratelyQuickly and accurately obtain payment informationRegistering coin as creditCoin-freed apparatus detailsRadio frequencyEngineering management

The present specification describes to a self-service payment device and a control method thereof. One example method includes determining that a removable cover plate is in a first state, wherein the removable cover plate and a payment box form an enclosed space when the removable cover plate is in the first state, and the top of the payment box is open when the removable cover plate is in a second state; reading, using at least one radio frequency identification (RFID) antenna fastened to at least one inner wall of the payment box, at least one RFID tag, wherein each RFID tag is associated with a merchandise to be paid inside the payment box; and providing payment information based on the at least one RFID tag.

Owner:ADVANCED NEW TECH CO LTD

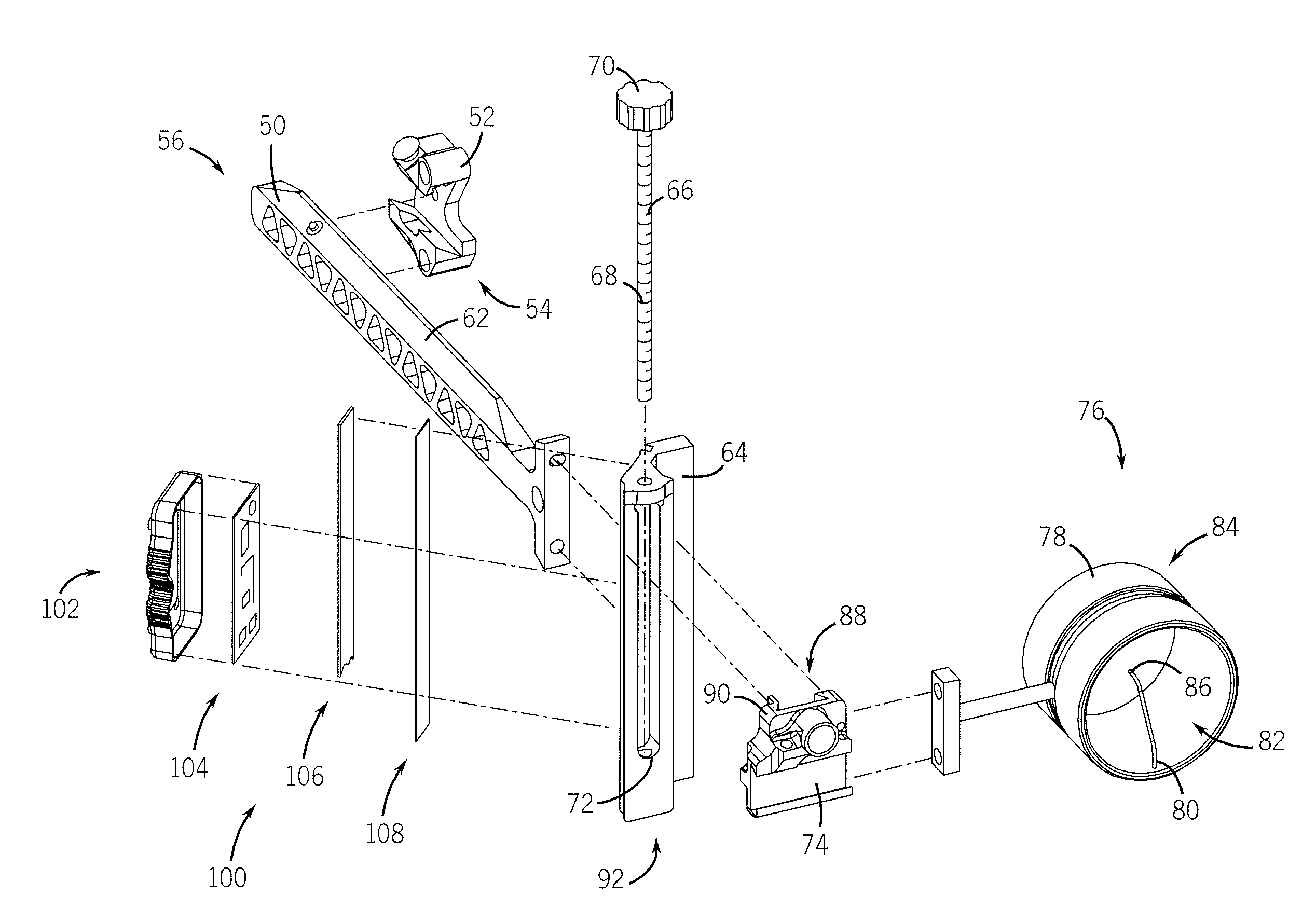

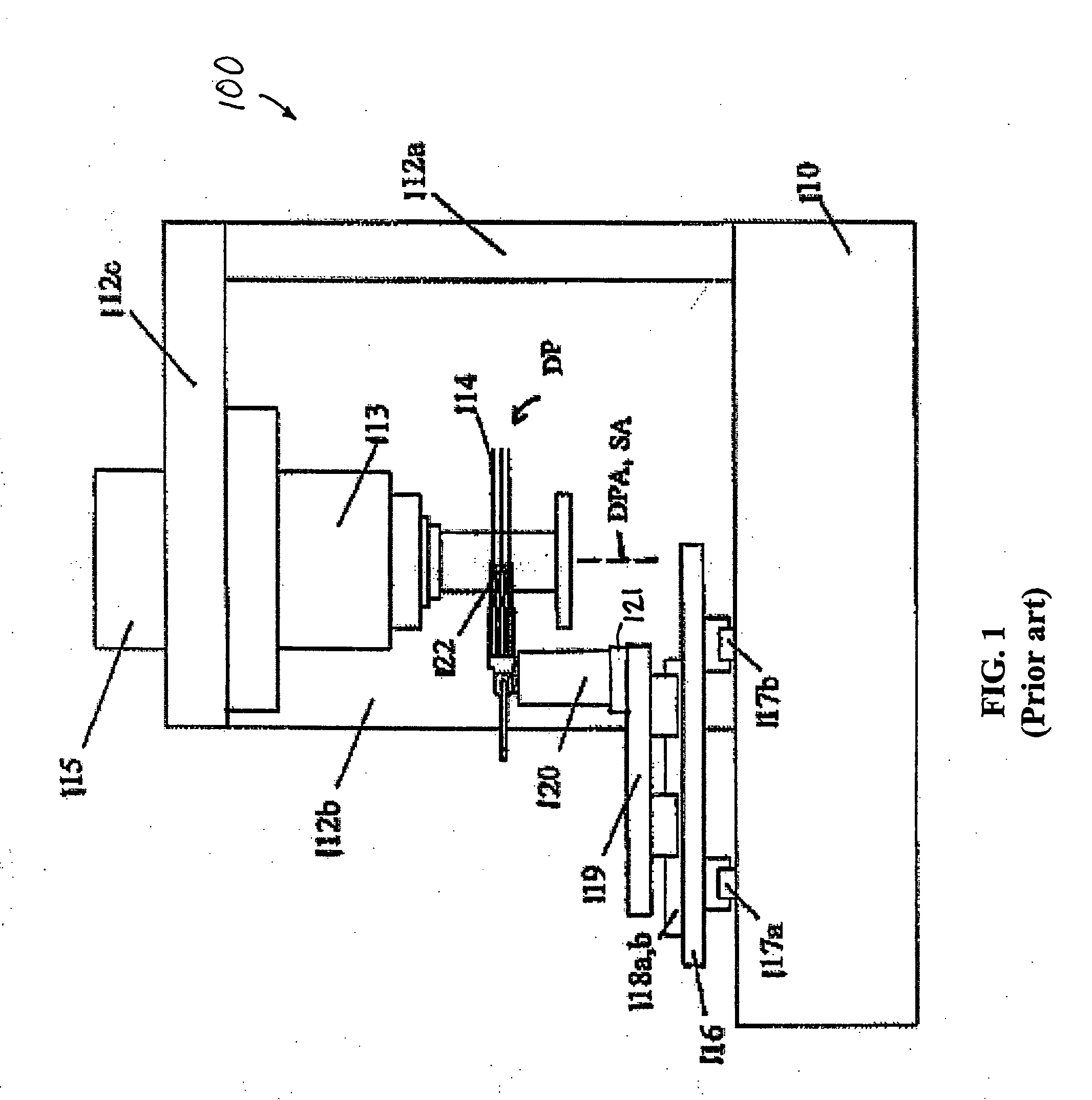

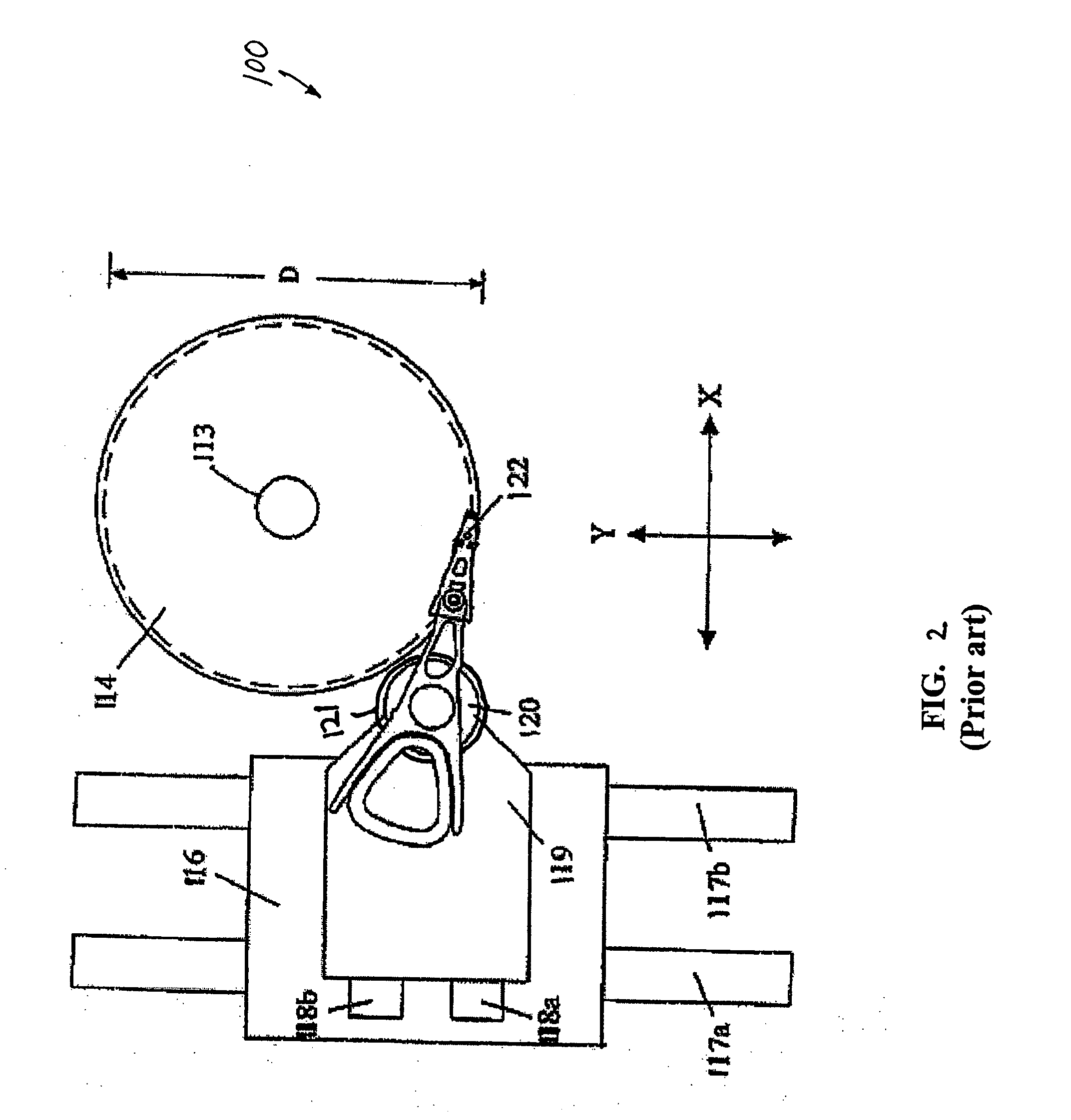

Headstack locator assembly for testing magnetic heads

InactiveUS20070017109A1Quickly and accuratelyMinimal wearMeasurement devicesRecord information storageEngineeringHead parts

A headstack locator assembly for locating and fixing a headstack on a spinstand and which mitigates the aforementioned prior art limitations. The headstack locator assembly includes a headstack locator received on a fixed locator. The headstack locator connects to a headstack, while the fixed locator is permanently secured to a spinstand. A vacuum is used to clamp the headstack locator to the fixed locator for testing of the headstack. Upon test completion, the headstack locator is released from the fixed locator by applying positive air pressure to the assembly.

Owner:GUZIK TECHN ENTERPRISES

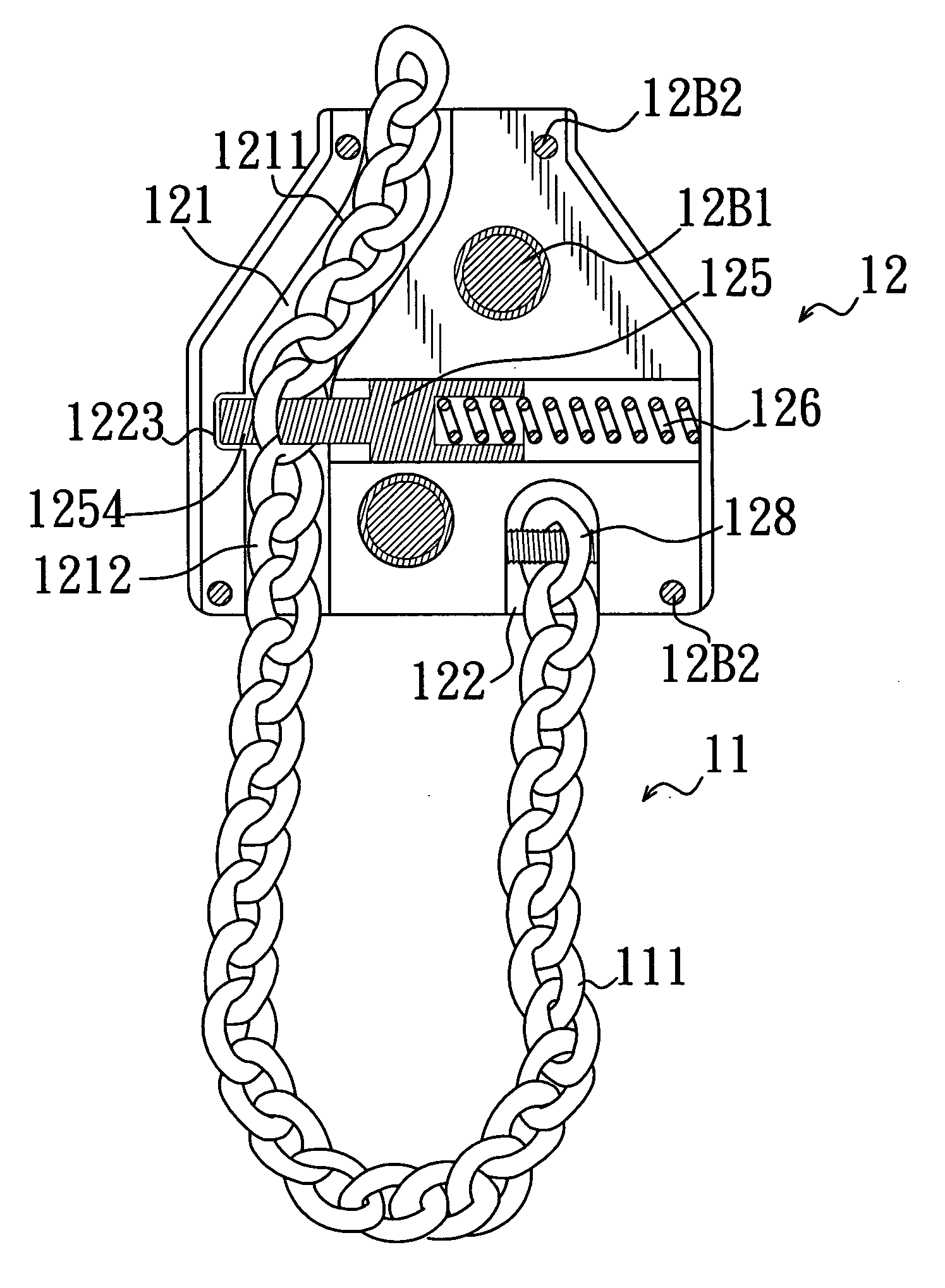

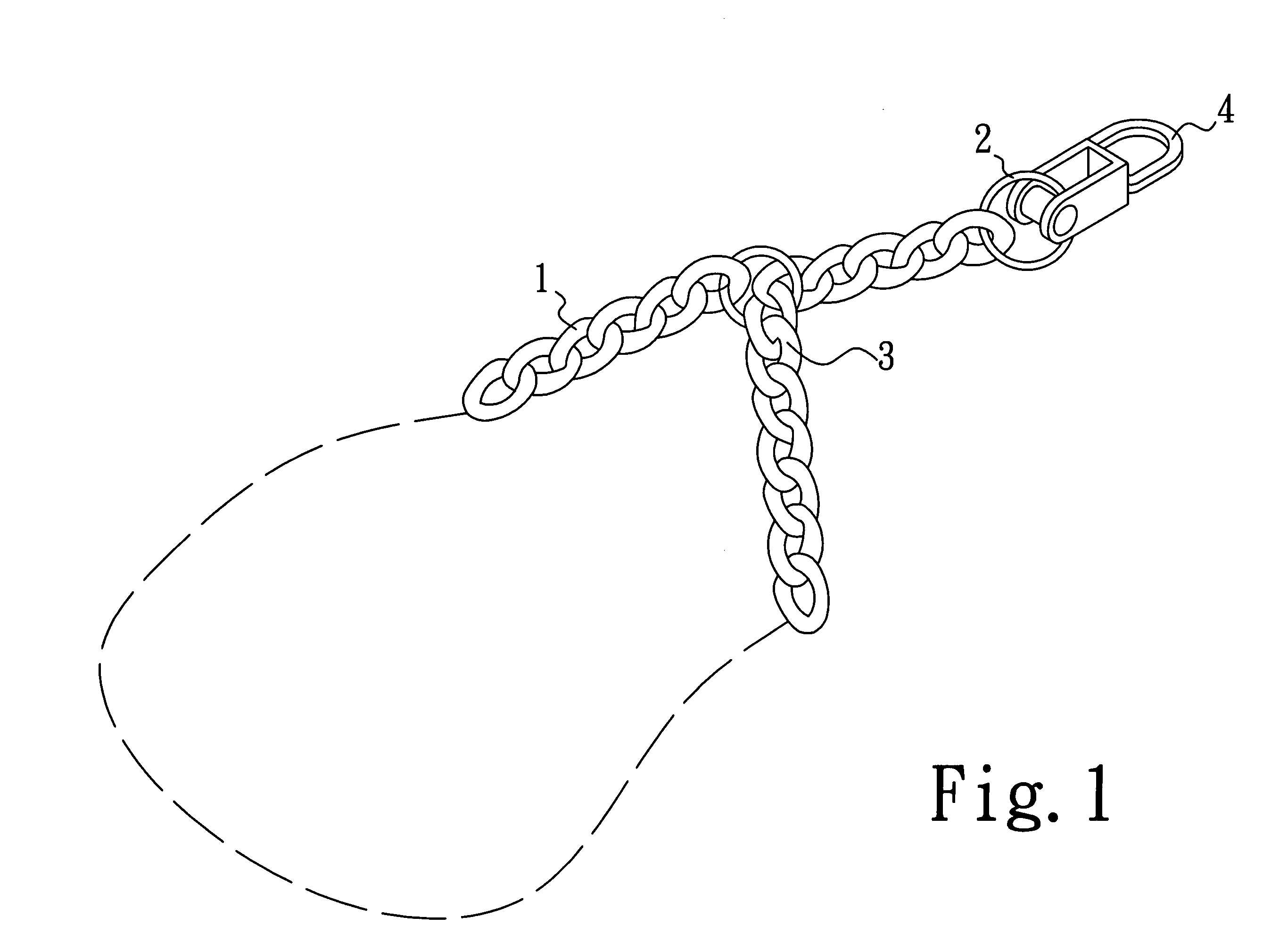

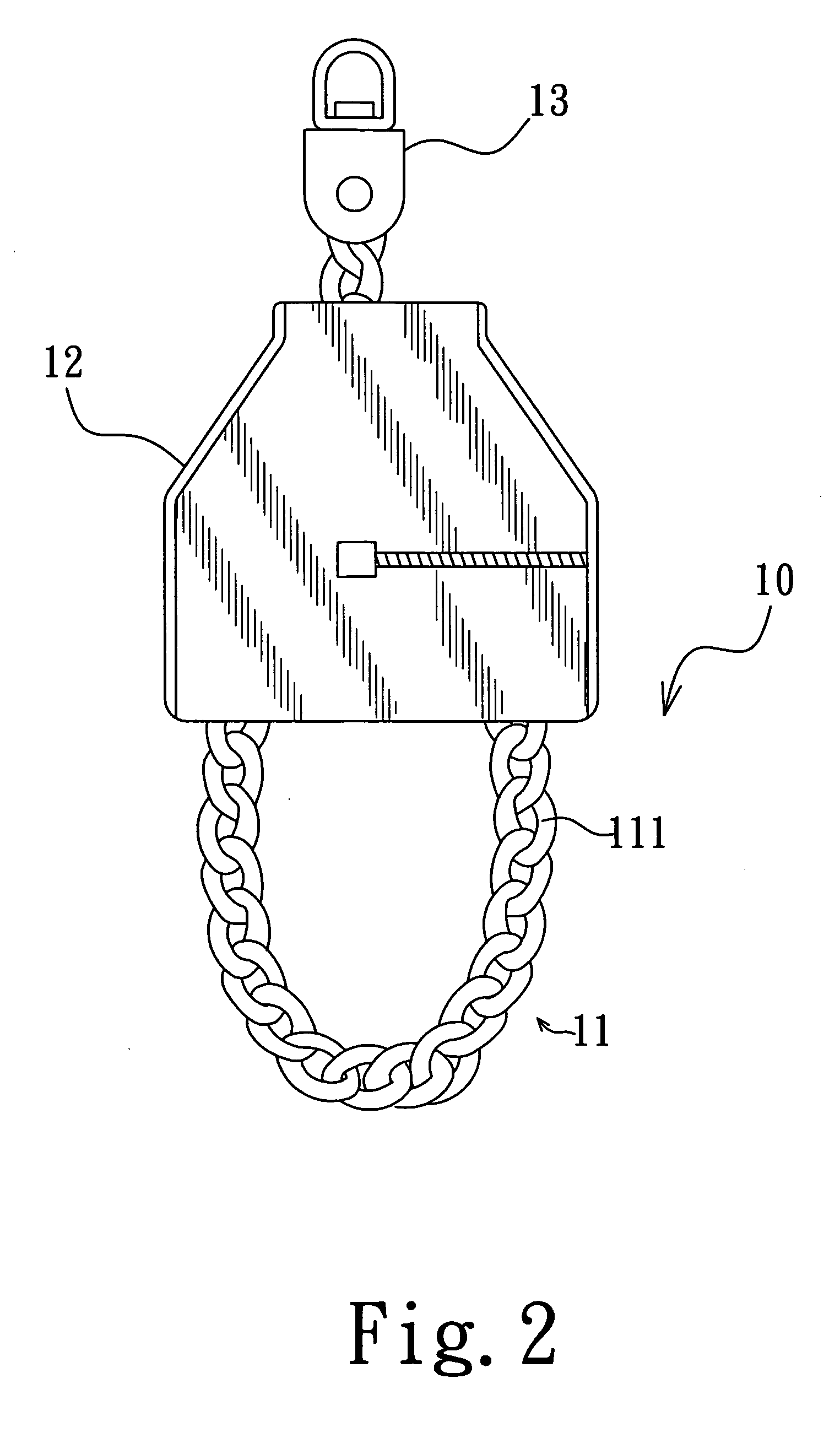

Adjustable pet collar

InactiveUS20060150924A1Quickly and accuratelyThe process is fast and accurateSafety beltsShoulder strapEngineeringMechanical engineering

An adjustable pet collar comprises a long chain and an adjuster. The adjuster is constructed by a upper cover and seat body, in which slit is opened on the upper cover and a slanting channel is disposed on the seat body. The chain is placed in said channel, and a sliding groove in which one end thereof is closed perpendicular to the channel is disposed at one side of the channel, and a recess groove is disposed at another end thereof. An inserting pin seat is installed in the sliding groove, and an elastic element is installed between the inserting pin seat and the closed end of the sliding groove. Whereby, the size of the collar formed by the chain is adjusted by the inserting pin seat.

Owner:LEE CHENG KAI

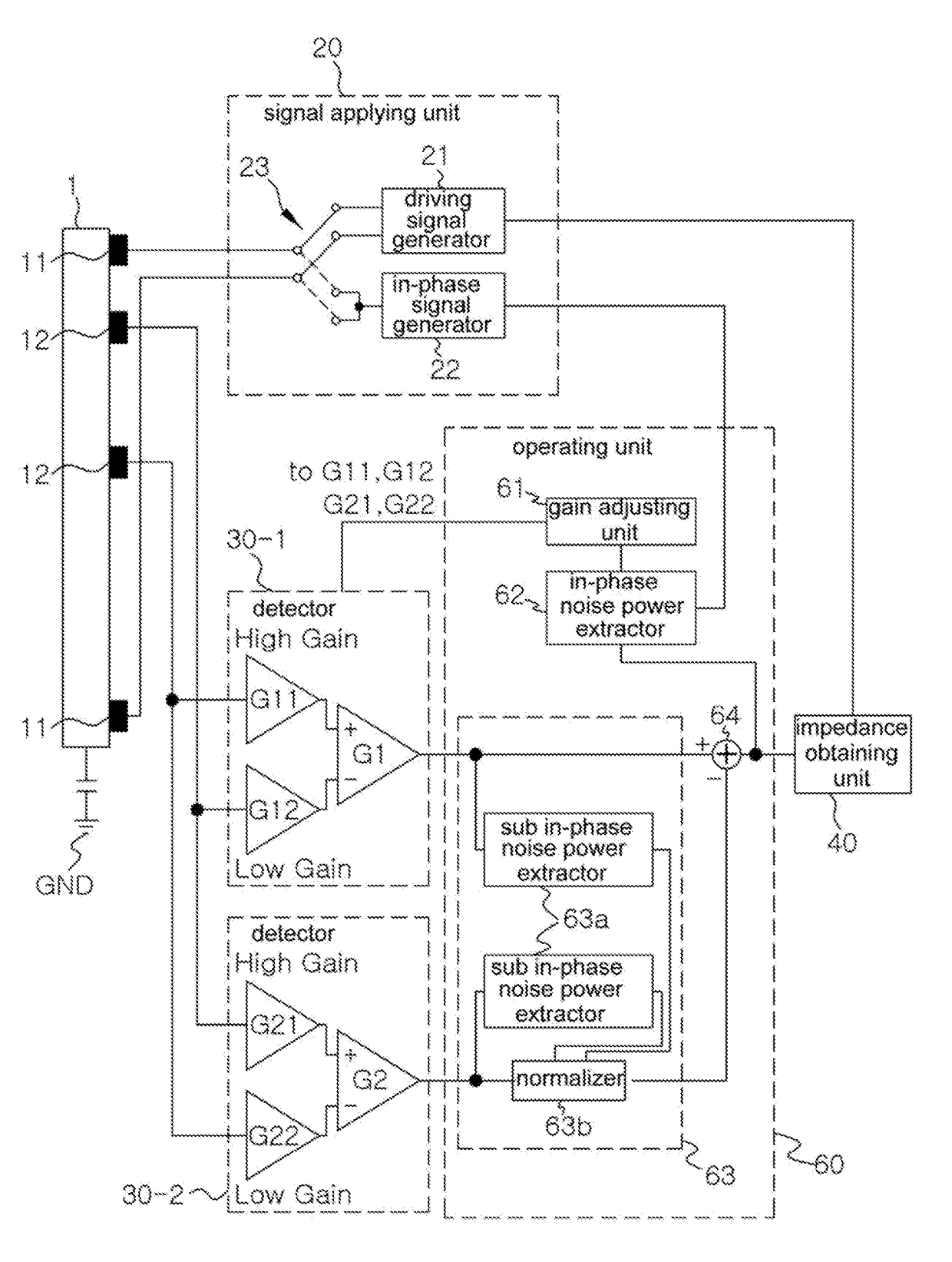

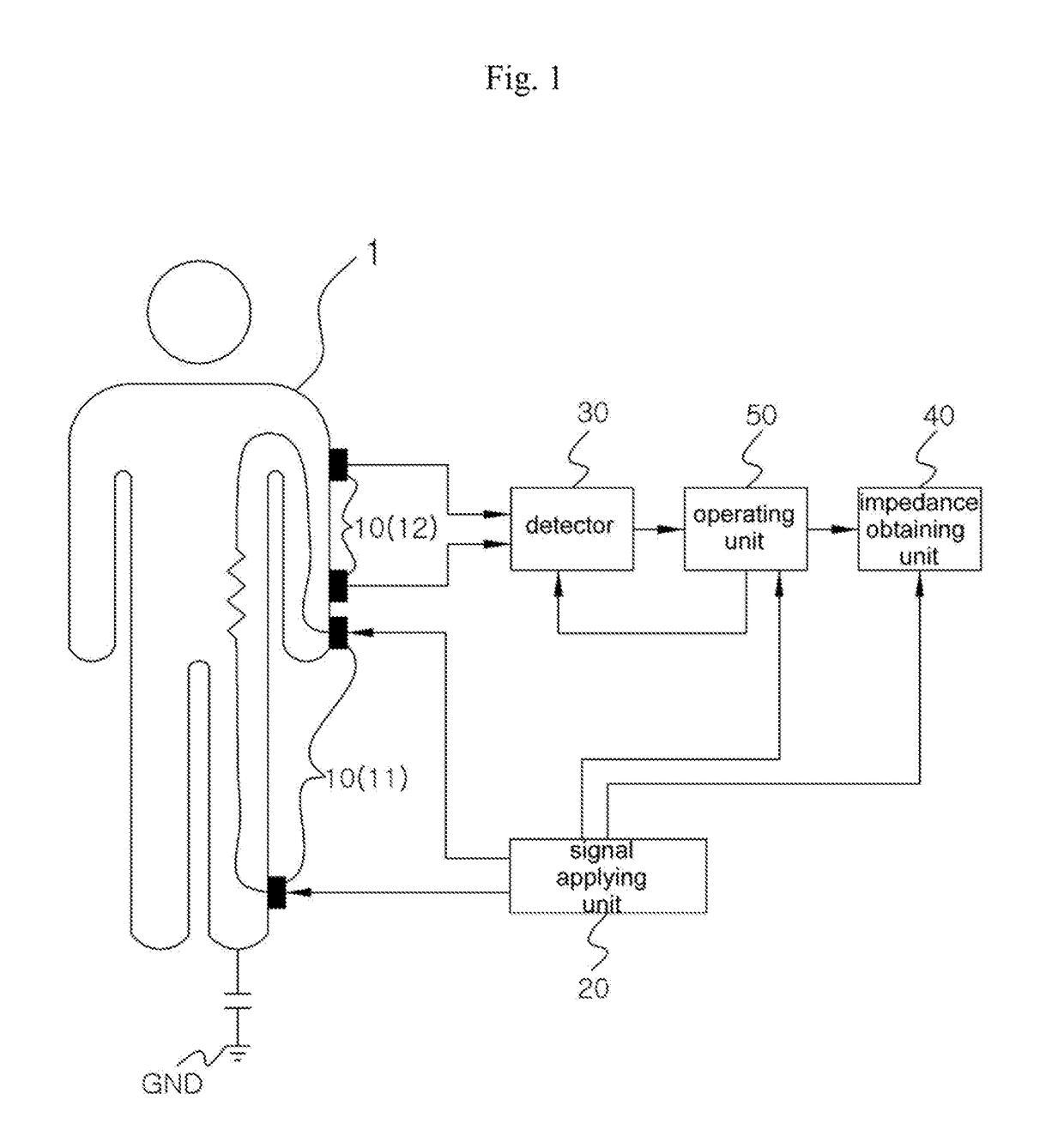

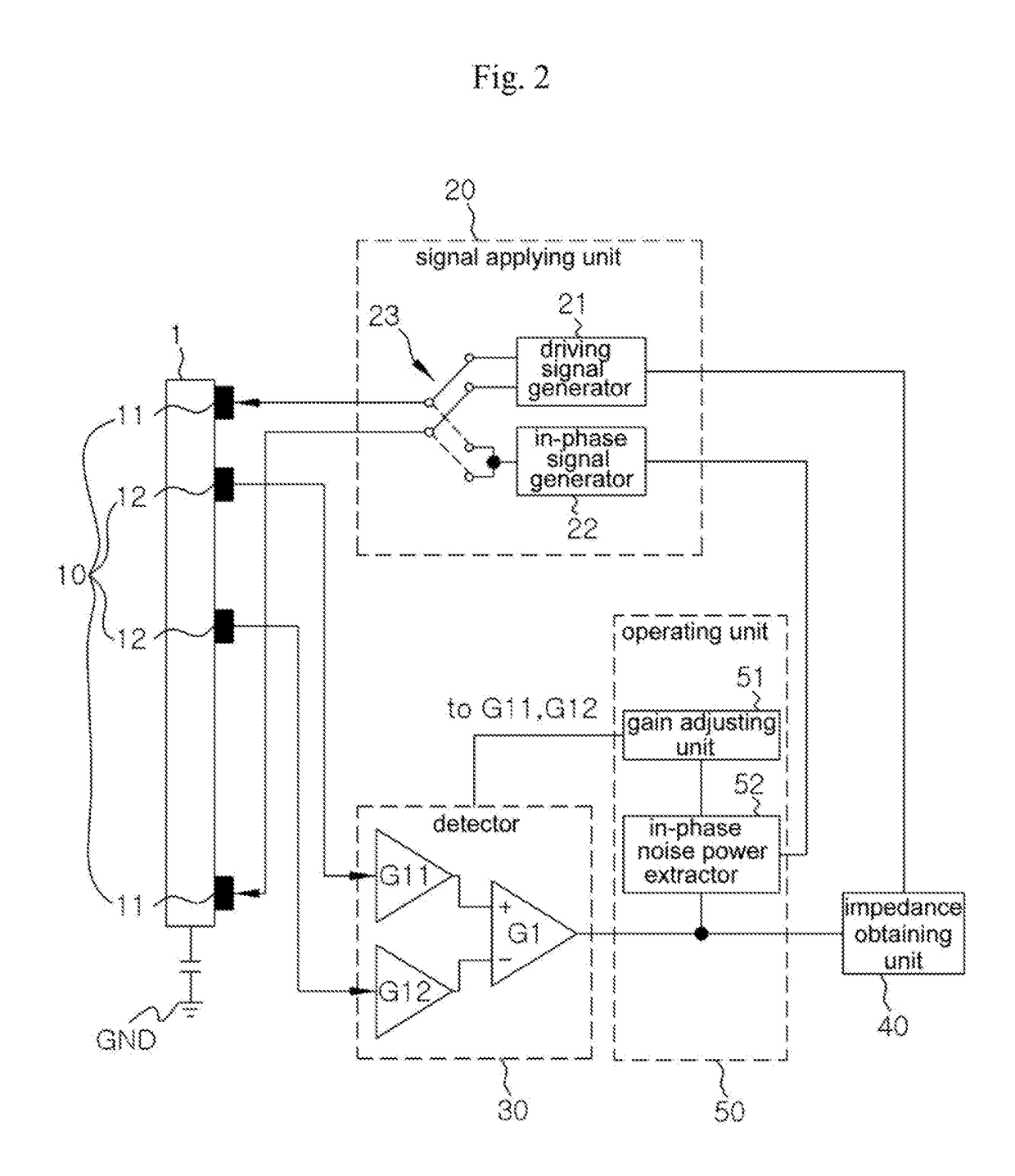

Impedance measuring device

InactiveUS20180116545A1Minimize noiseQuickly and accuratelyBioelectric signal measurementImpedence measurementsElectricityAudio power amplifier

The present invention relates to an impedance measuring device obtaining impedance of portions of an object corresponding to two sensing electrodes by detecting, through the two sensing electrodes, an electrical variation shown on the object as an electrical signal is applied. A detector amplifying each of signals detected through the two sensing electrodes and then differential-operating the amplified signals to generate a signal for obtaining impedance is subjected to a calibration process for adjusting the gain of the amplifiers to reduce in-phase noise added due to an imbalance between the sensing electrodes.

Owner:ROEMSYST

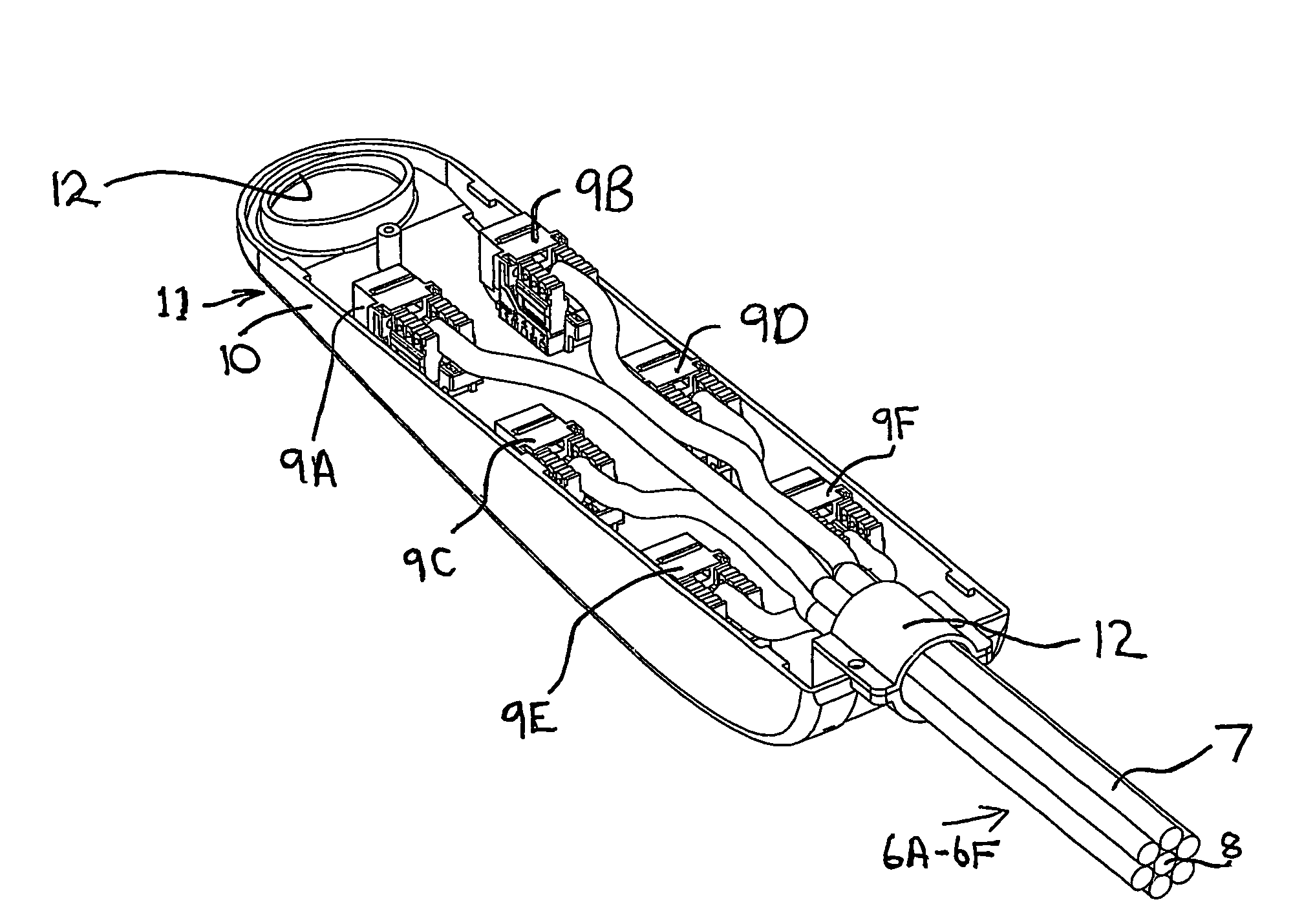

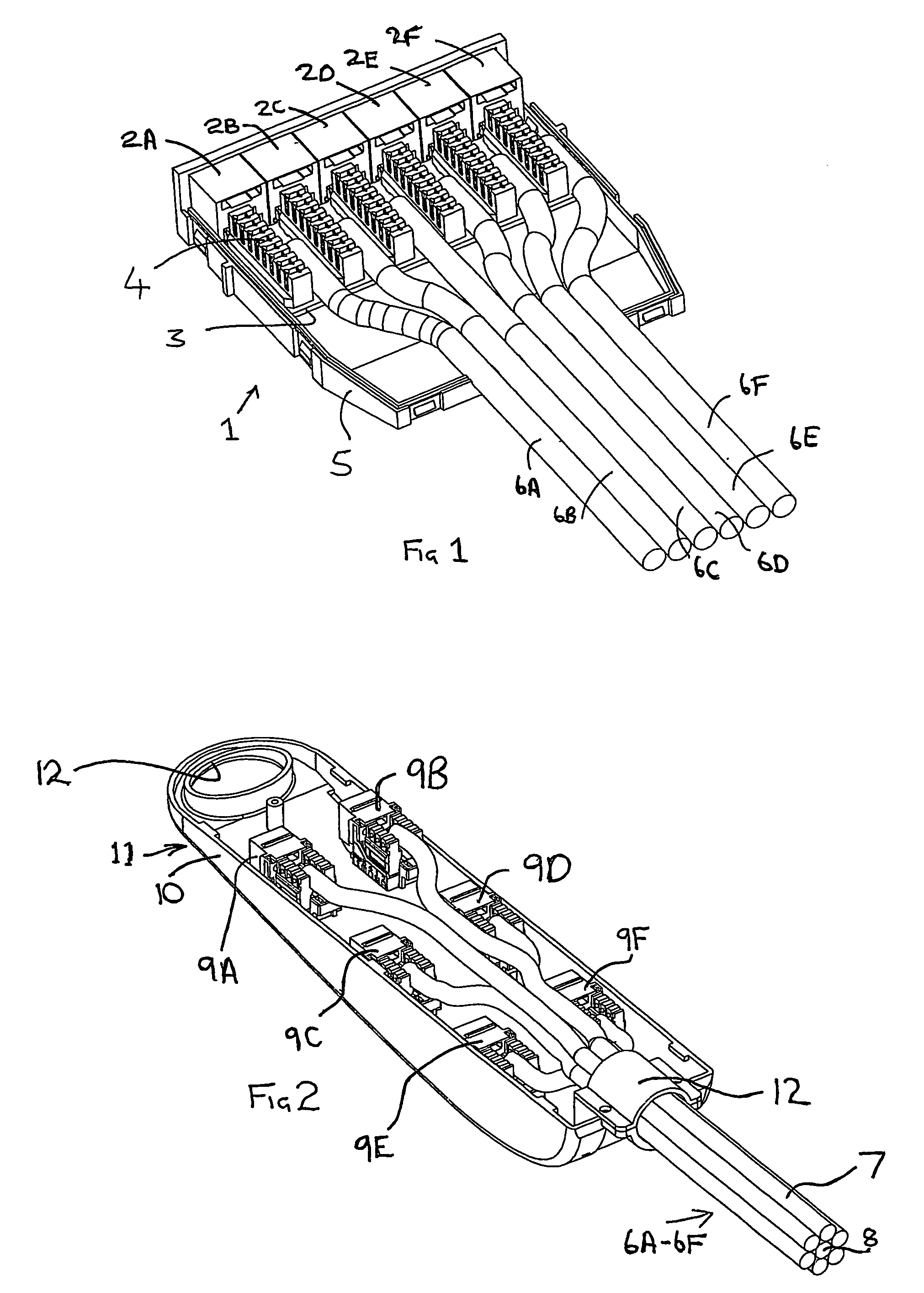

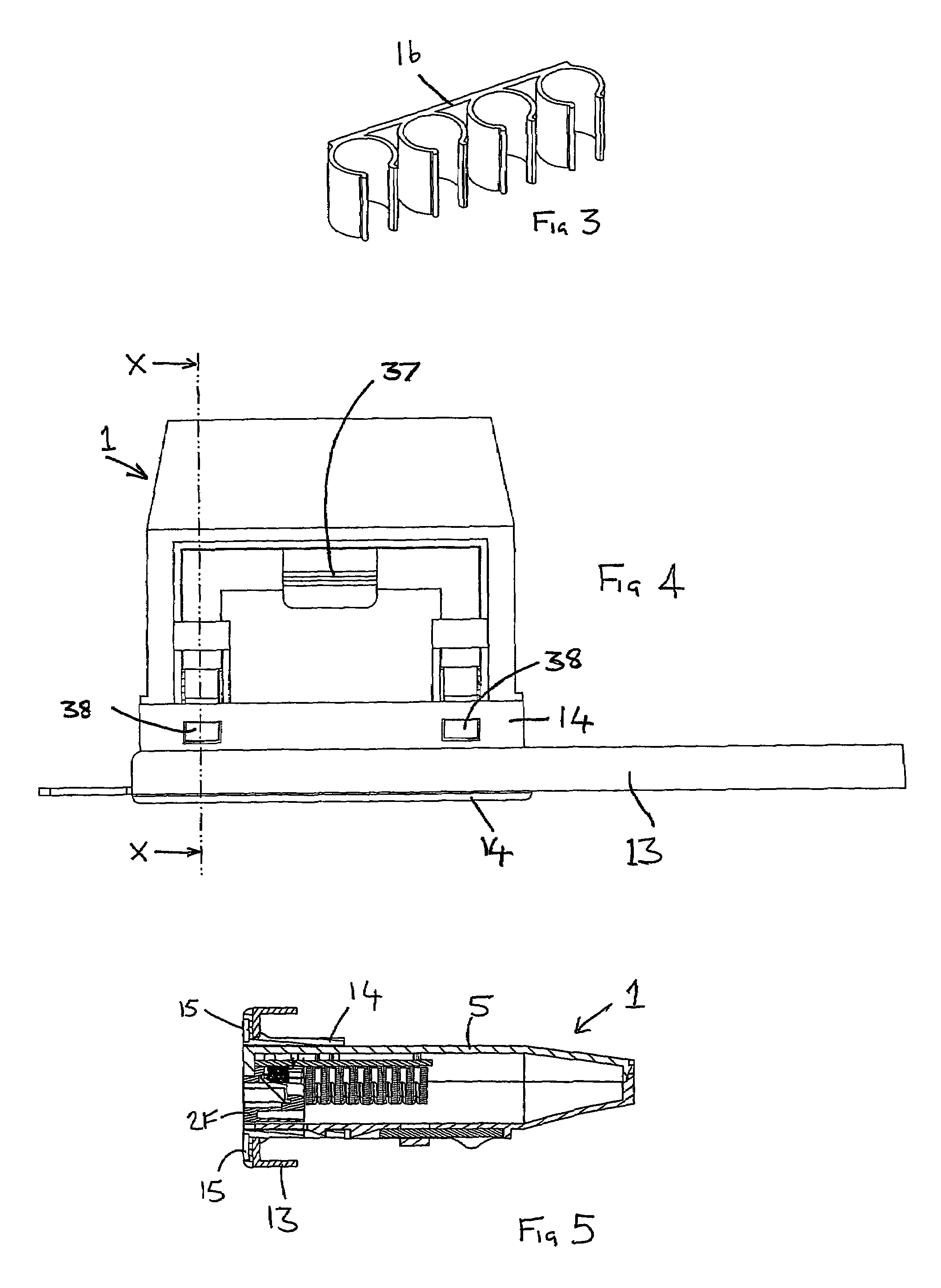

Structured cabling system and method

ActiveUS7375282B2Quickly and accuratelyQuickly instalElectrically conductive connectionsCoupling device detailsStrain reliefMechanical engineering

A structured cabling system includes a plurality of data cables (6A-6F), one end of each cable being secured to a jack of a multiple jack assembly (1) and the other end of each cable being secured to an individual jack (9A-9F) located within a protective enclosure (11). The individual cables are mechanically secured to at least the protective enclosure (11) and / or a strain relief member (8) within the cable bundle is secured to the protective enclosure (11). The entire assembly may be pre-formed under factory conditions and delivered to an installation site. The multiple jack assembly (1) may then be secured, preferably by snap-fitting, to a rack assembly and the protective enclosure (10) may be used to draw the entire cable length to the required position. Once the cable is in position the protective enclosure (10) is discarded and the jack secured to their final use positions. In an alternative embodiment the protective enclosure forms a housing for jacks (9A-9F) in their final use position and may, for example, be snap-fitted to a floor box for this purpose.

Owner:HELLERMANNTYTON DATA

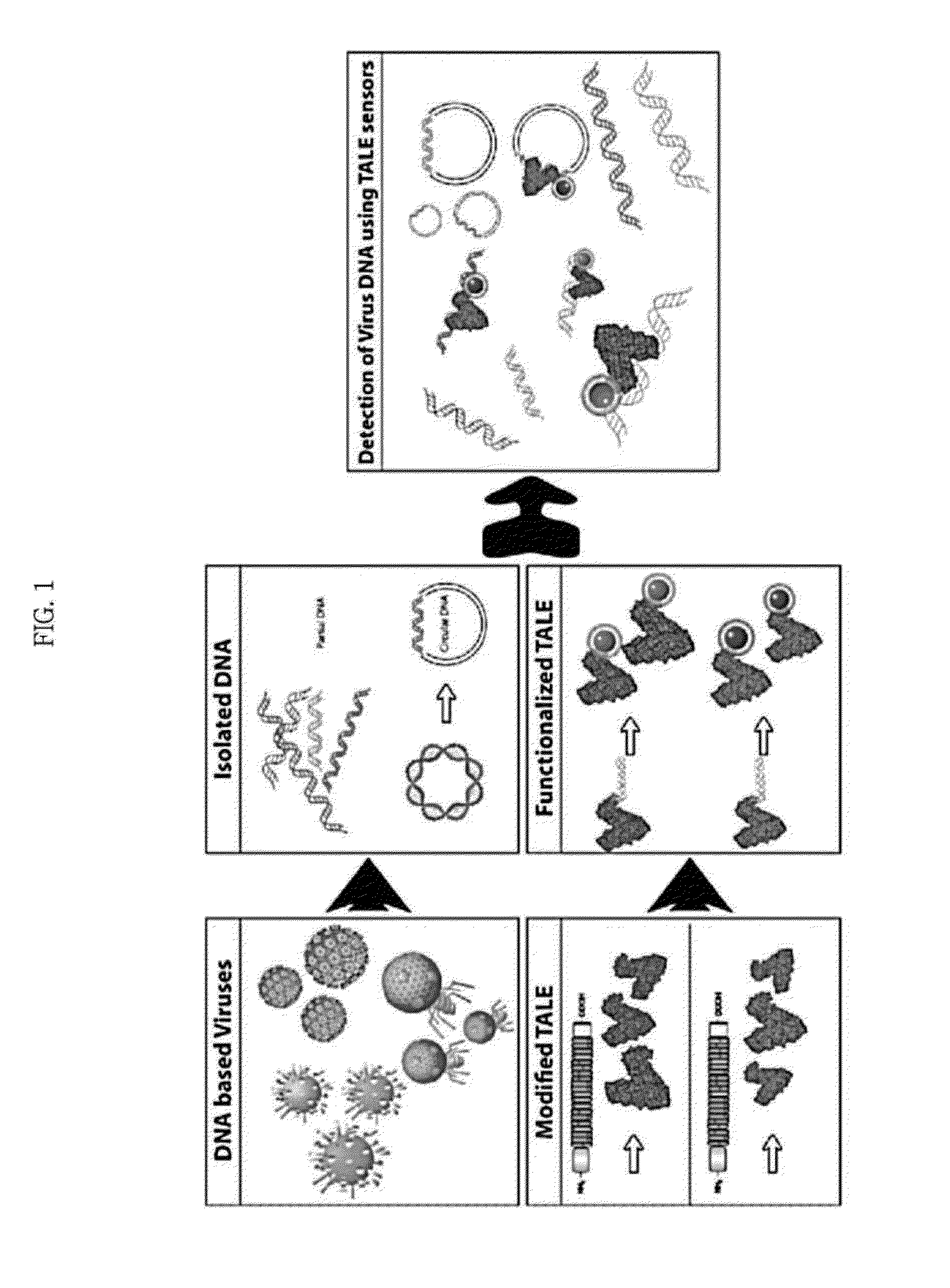

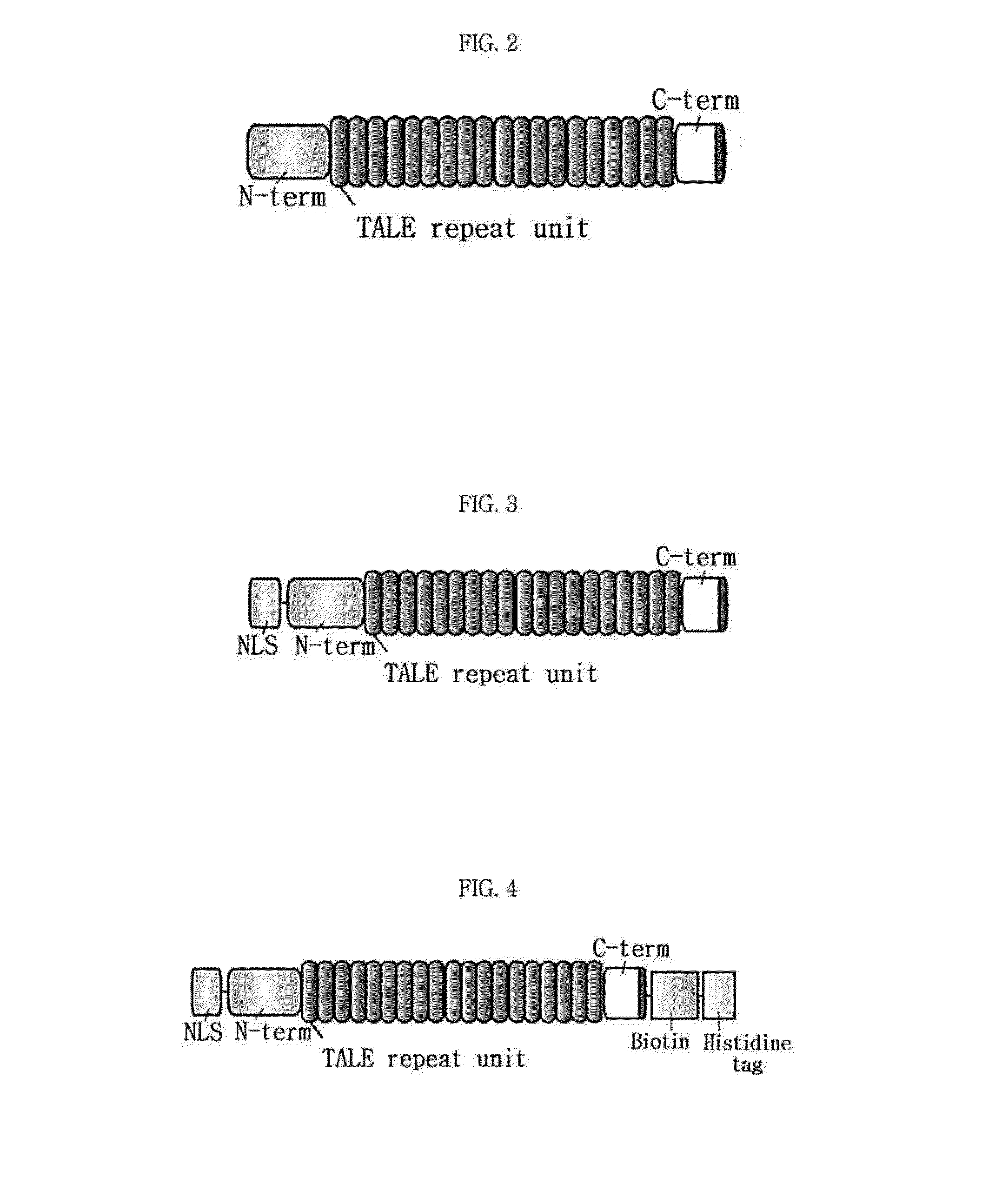

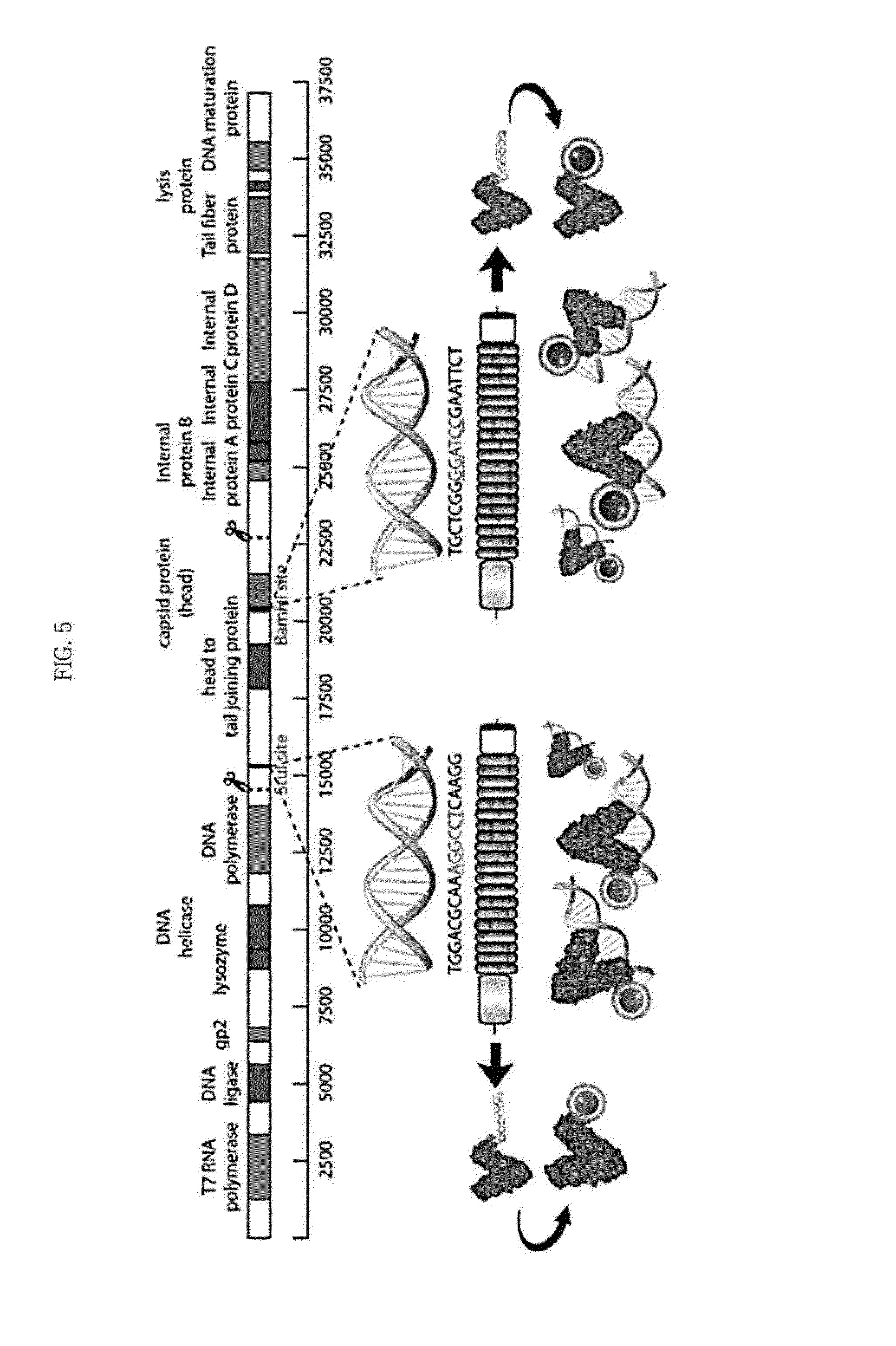

Composition for detection or diagnosis of diseases containing transcription activator-like effector

InactiveUS20160041172A1Easy and convenientQuickly and accuratelyMicrobiological testing/measurementBiological material analysisTranscription Activator-Like EffectorsDisease

Owner:KOREA INST OF SCI & TECH

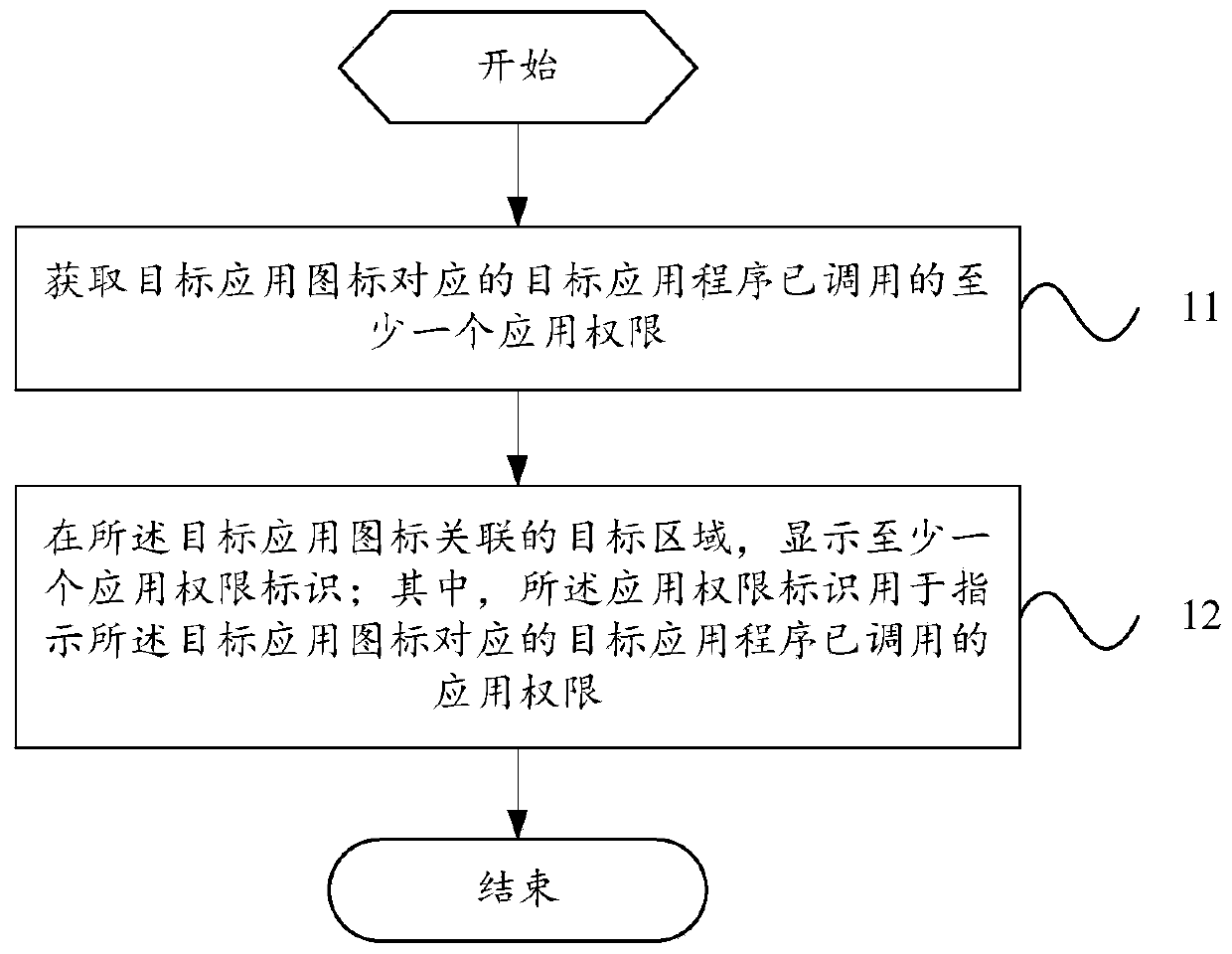

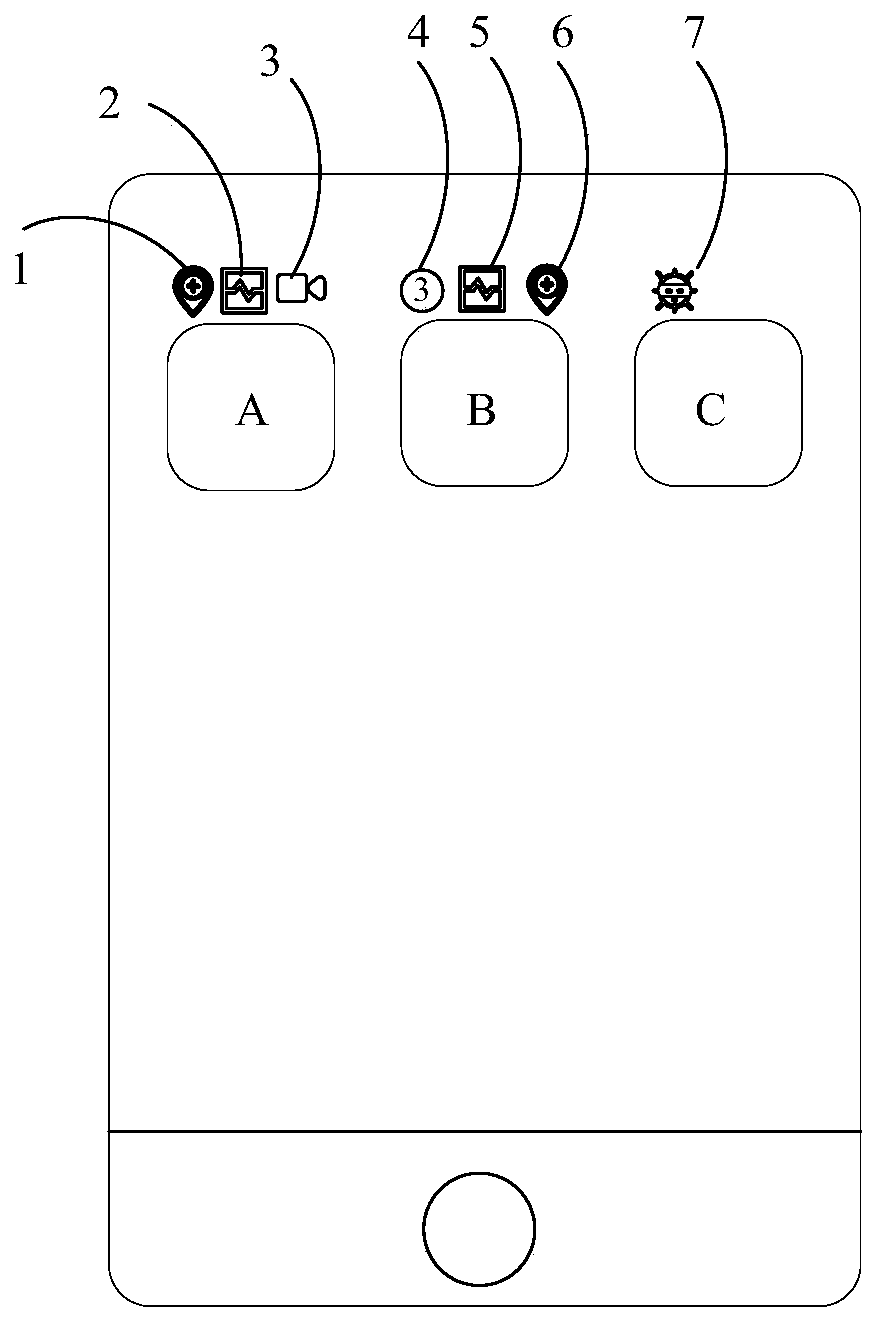

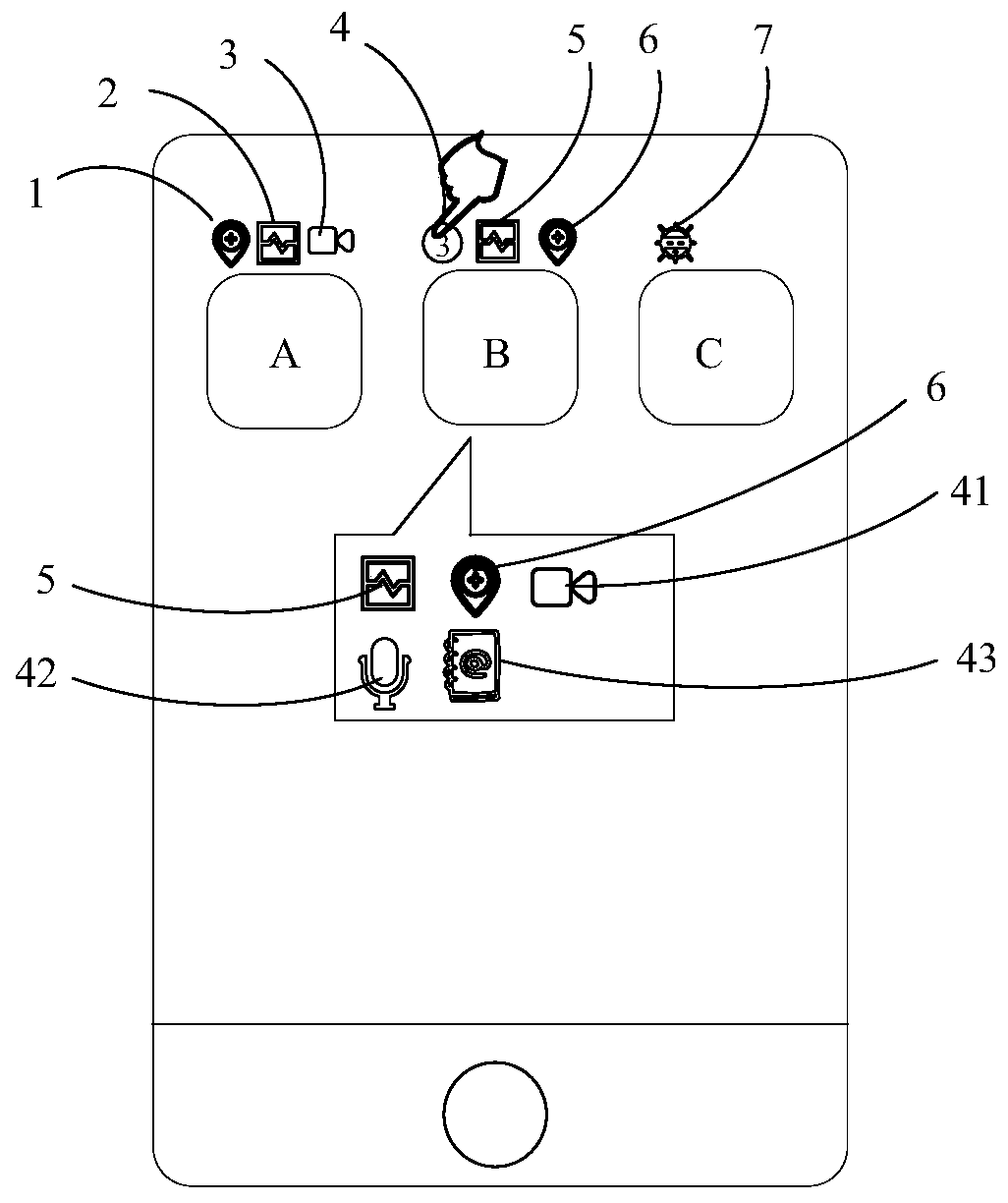

Application permission calling monitoring method and electronic equipment

PendingCN111460397AIntuitively knowQuickly and accuratelyProgram/content distribution protectionApplication procedureEngineering

The invention provides an application permission calling monitoring method and electronic equipment, and relates to the technical field of communication. The method comprises the steps of obtaining atleast one application permission called by a target application corresponding to a target application icon; displaying at least one application permission identifier in a target area associated withthe target application icon; wherein the application permission identifier is used for indicating application permission called by a target application program corresponding to the target applicationicon. According to the scheme, the at least one application permission identifier is displayed in the target area associated with the target application icon, so that a user can visually, quickly andaccurately know the application permission called by the APP, the operation is simpler, and the time for querying the application permission called by the APP by the user is saved.

Owner:VIVO MOBILE COMM CO LTD

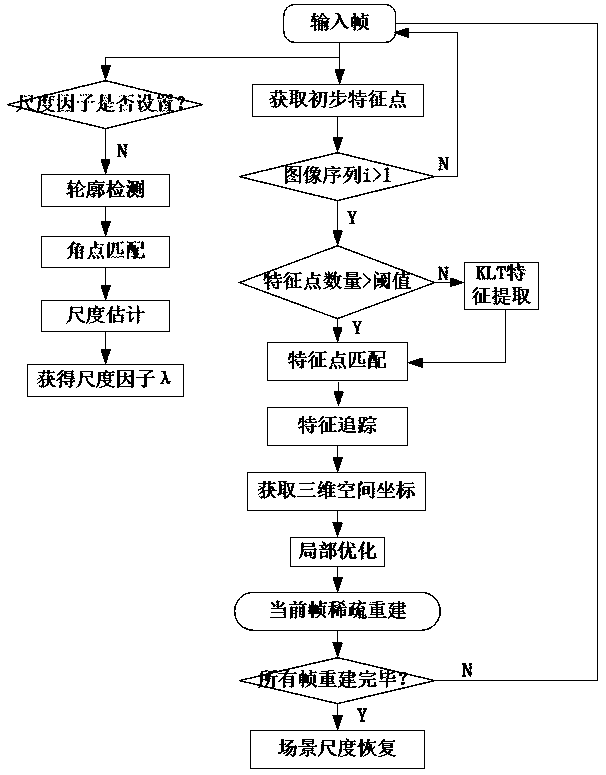

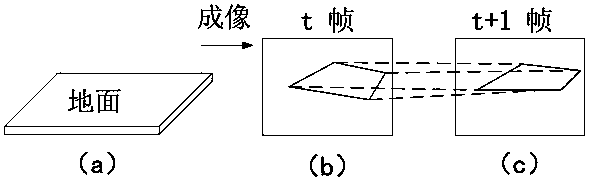

Scale reduction method and system, three-dimensional reconstruction method and system, storage medium and equipment

ActiveCN111402429AImprove reliabilitySolve the problem of scale ambiguityImage data processingGeometric relationsAlgorithm

The invention provides a scale reduction method and system, a three-dimensional reconstruction method and system, a storage medium and equipment, and aims at solving the technical problem that compared with traditional monocular three-dimensional reconstruction, the development cost and the data processing complexity of the prior art are increased. The method comprises the steps: obtaining an i-thkey frame; obtaining a j-th key frame at the position with the translation vector Ti, j away from the i-th key frame; wherein each angular point coordinate of the i-th key frame is correspondingly matched with each angular point coordinate of the j-th key frame; according to the i-th key frame angular point coordinate and the j-th key frame angular point coordinate, obtaining a geometrical relationship between the i-th key frame and the j-th key frame, and obtaining a scale factor lambda for three-dimensional reconstruction.

Owner:CHENGDU SOBEY DIGITAL TECH CO LTD

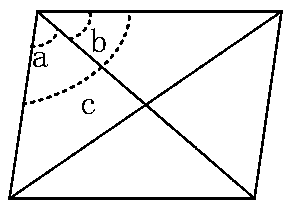

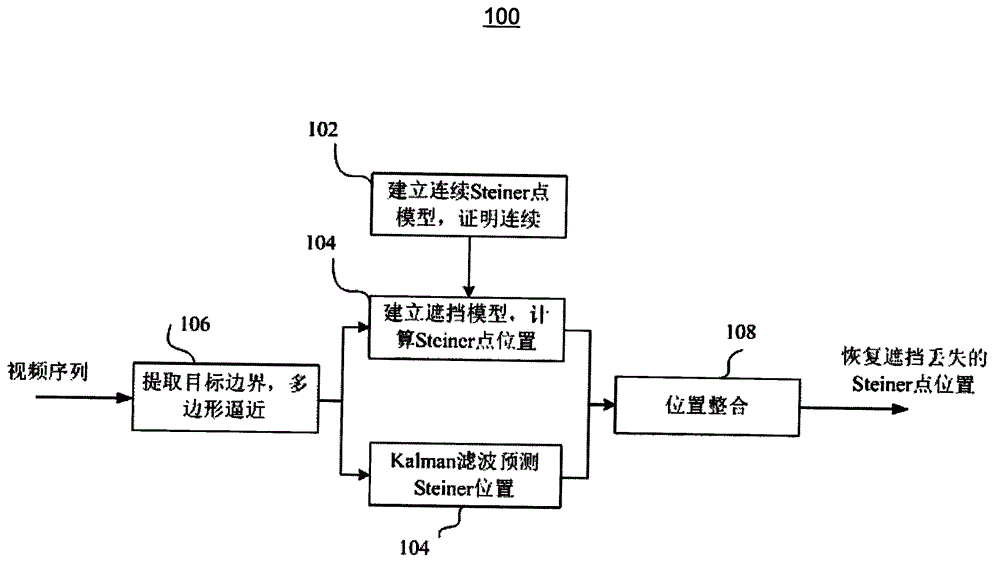

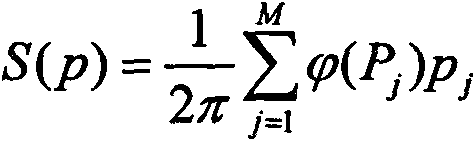

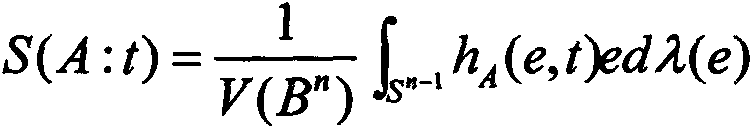

Moving target shielding and restoring method based on Steiner point

InactiveCN104680499AQuickly and accuratelyImage enhancementImage analysisEuclidean vectorComputer science

The invention discloses a moving target shielding and restoring method based on a Steiner point. The method comprises the following steps: treating a moving target in a video, firstly, extracting the boundary of the moving target, and converting into a convex polygon which is easy to treat after convex-shell treatment and polygon approximation processes; calculating the offset vector of the moving target at the Steiner point by adopting a derived shielding conclusion, and combining with the Steiner point of a shielded region, so as to calculate the position of a characteristic point-Steiner point of the moving target, and thus, the problem of shielding is solved. The shielding of the target in the movement process is realized by adopting the method based on a curvature center; and the center of the target is accurately restored, so that the moving track of an object can also be accurately predicted even if the shielding appears, and the characteristic center of the object is restored.

Owner:JIANGNAN UNIV

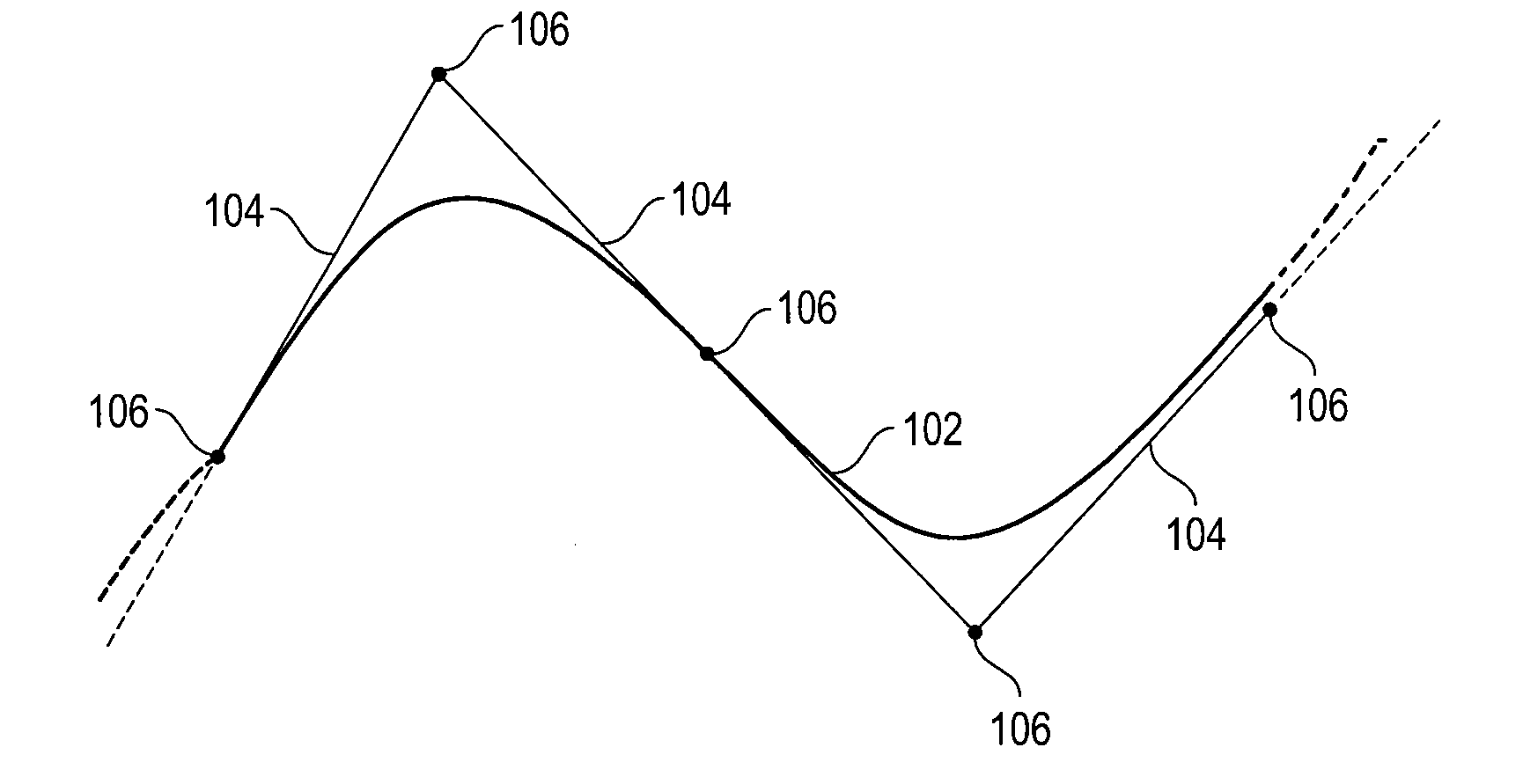

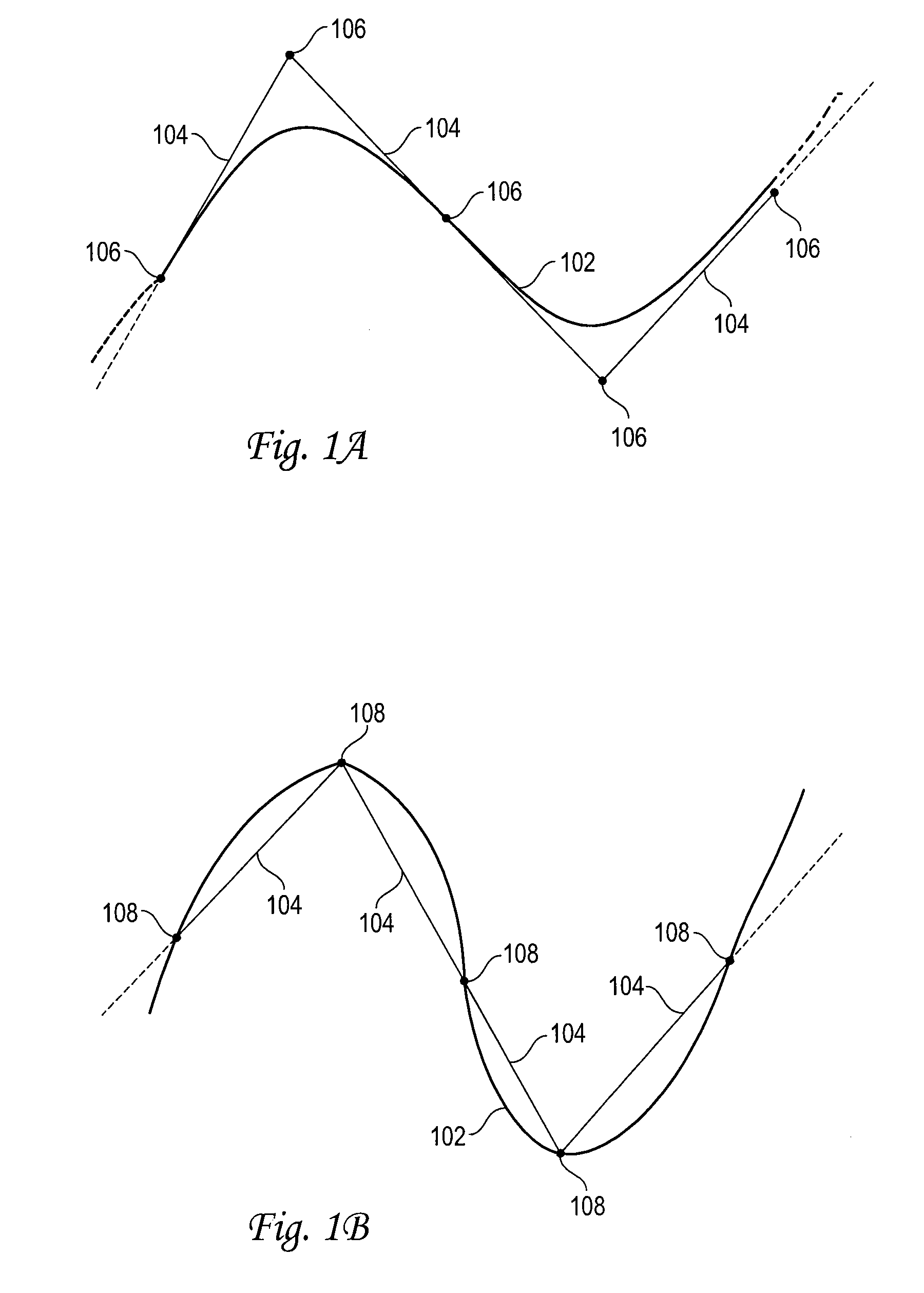

Method and apparatus for approximating hair and similar objects during animation

ActiveUS20100045679A1Quickly and accuratelyApproximate accurately and quicklyDrawing from basic elementsAnimationComputer basedLine segment

Simulating dynamics (e.g., physical effects of inertia, forces, wind) on strands (e.g., hair) during computer based animation requires quick and accurate approximations of mathematical curves. Each strand is initially represented as a B-spline curve. Line segments approximating the curve are created by using affine combinations based on the curve's control vertices. Dynamics simulation is performed on the line segment approximation. Once an approximated strand is simulated, it is converted back into a B-spine curve representation for downstream processes, such as rendering. The rendering process displays the simulated strand to the animator.

Owner:PACIFIC DATA IMAGES

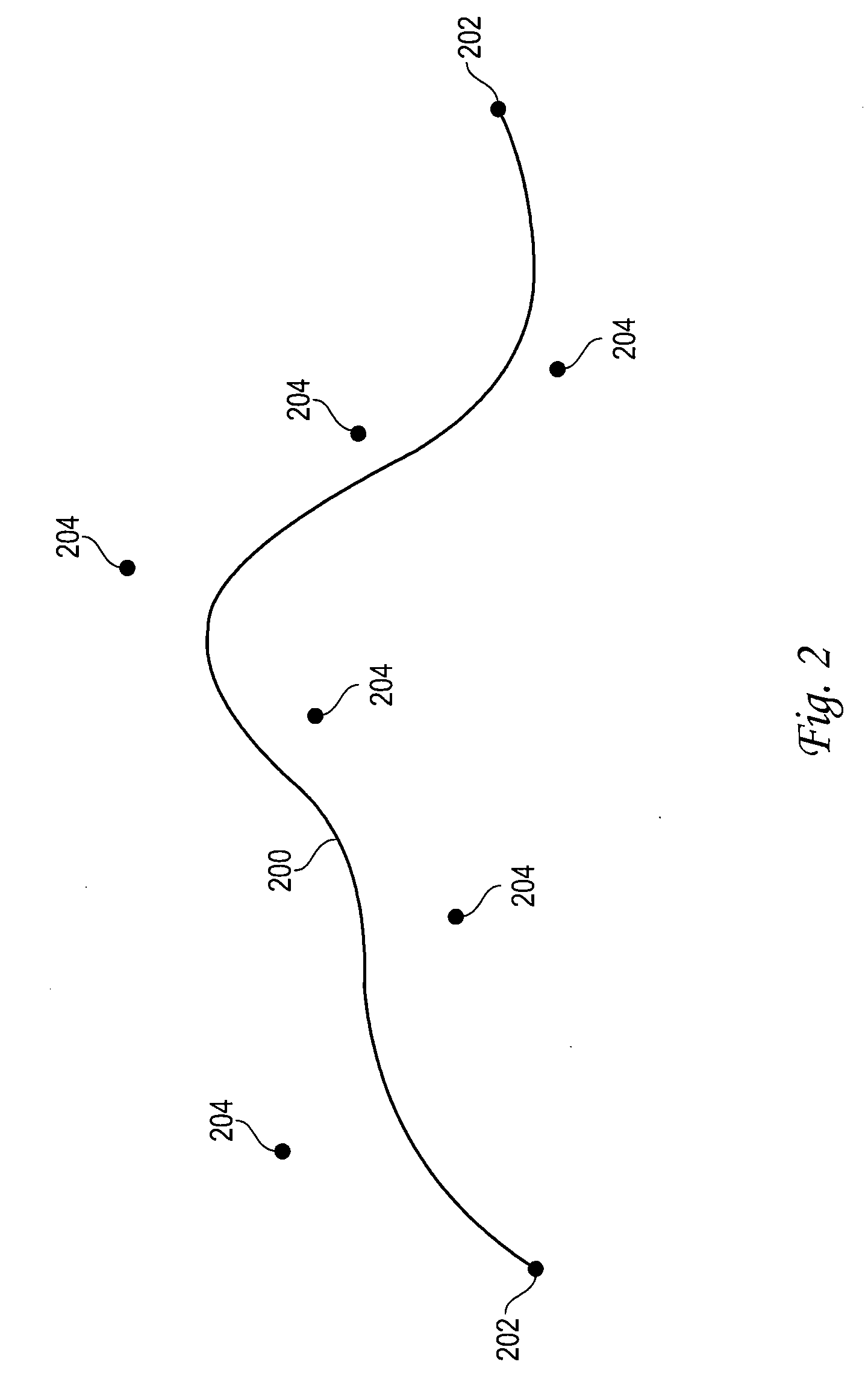

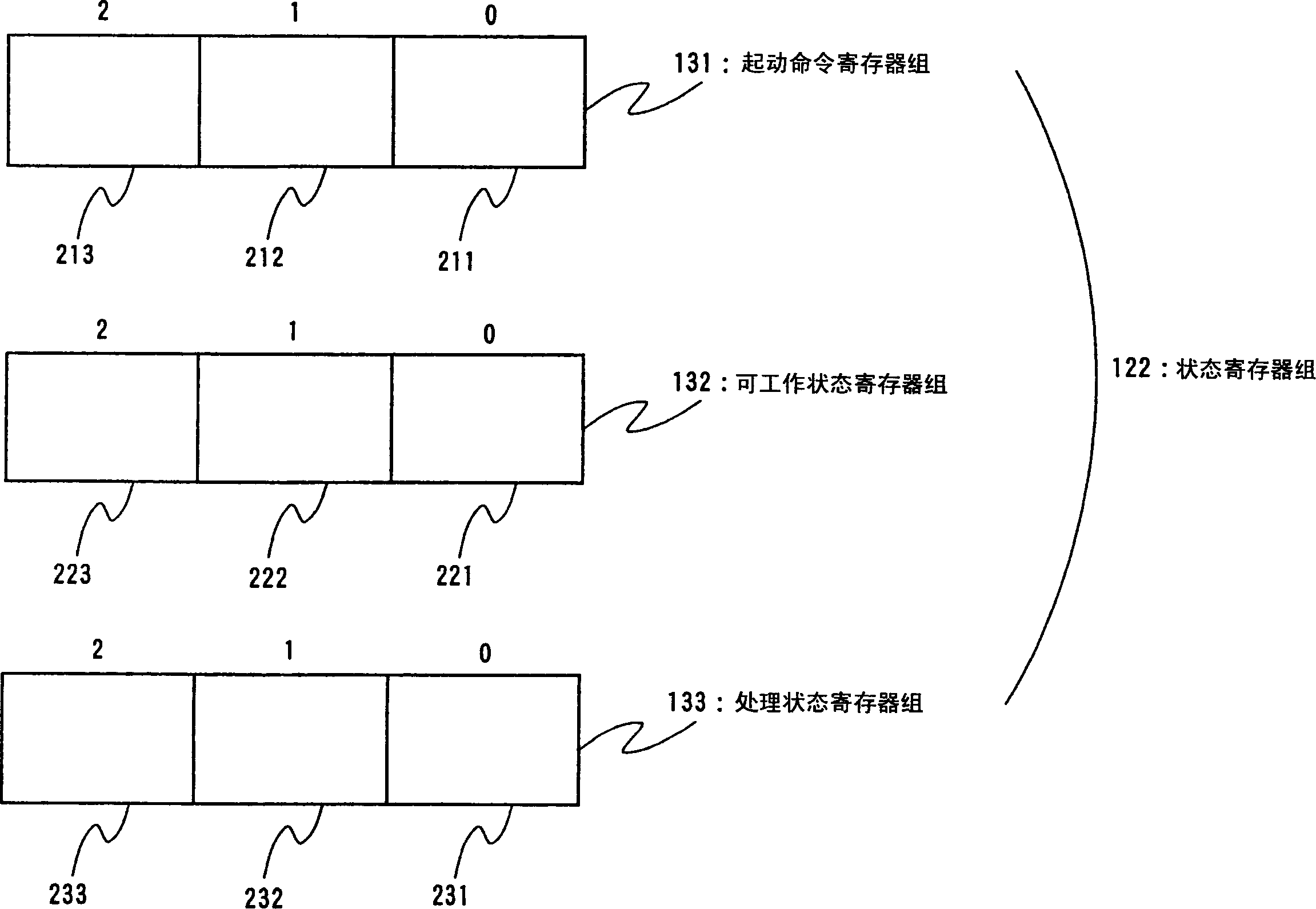

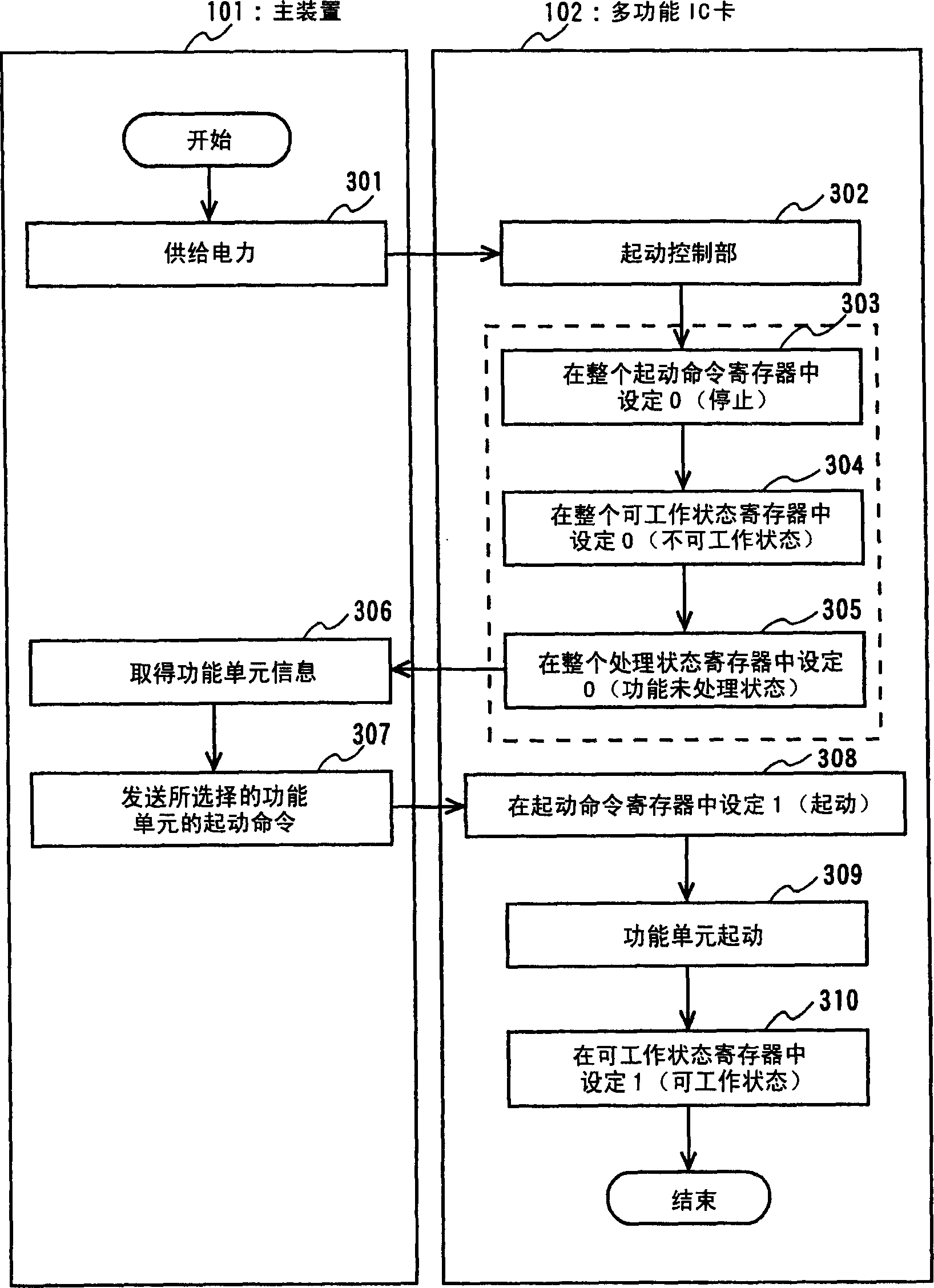

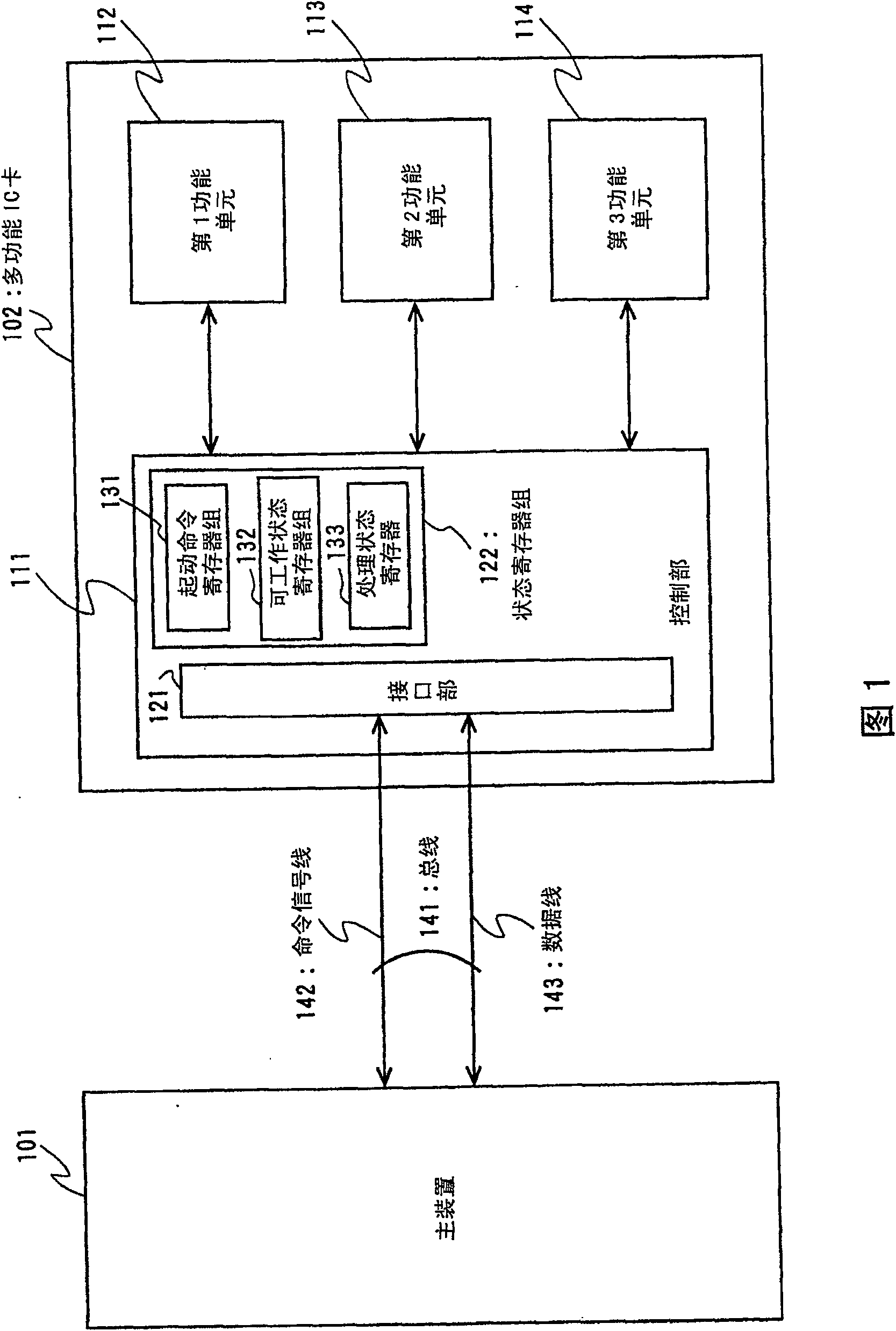

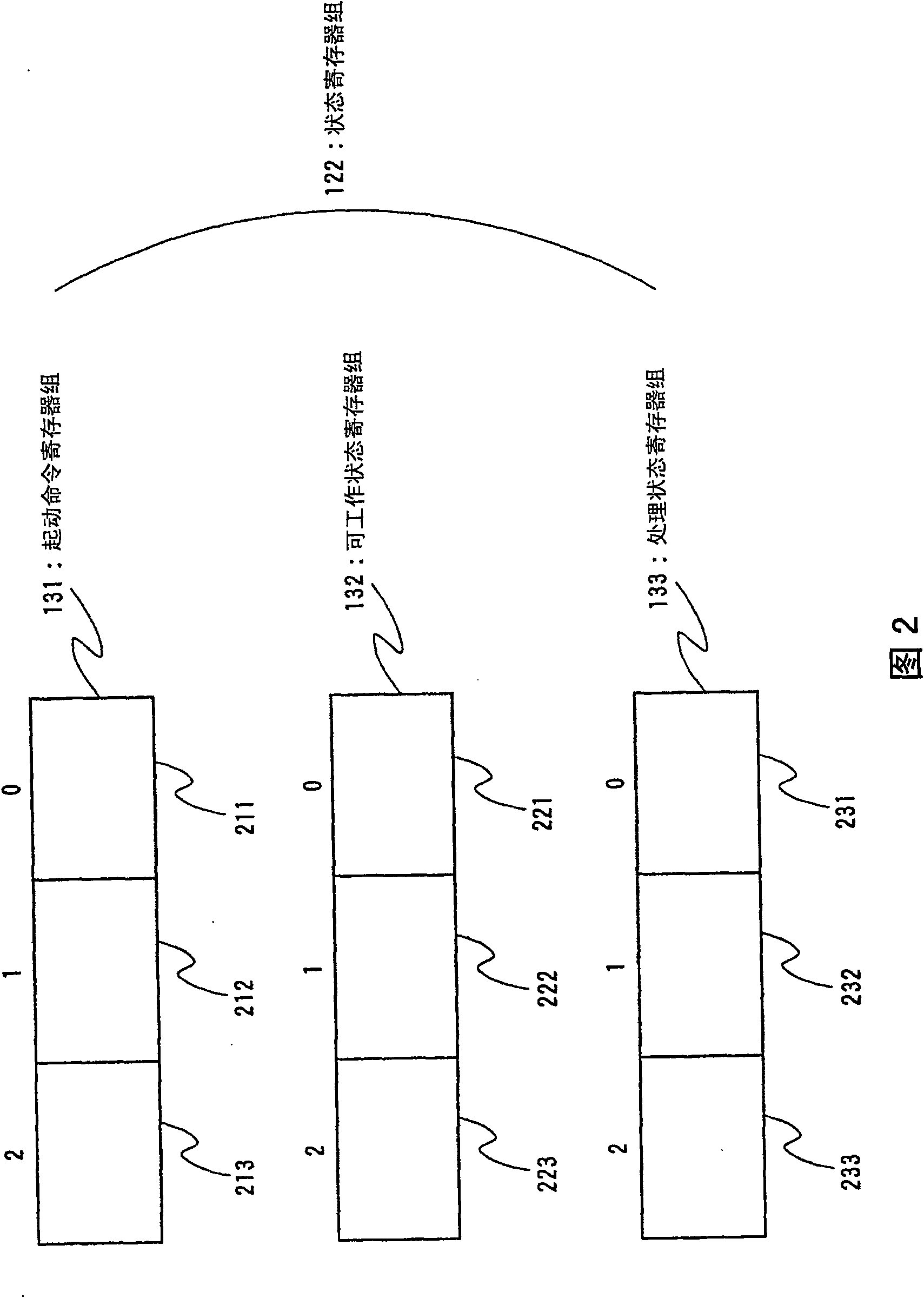

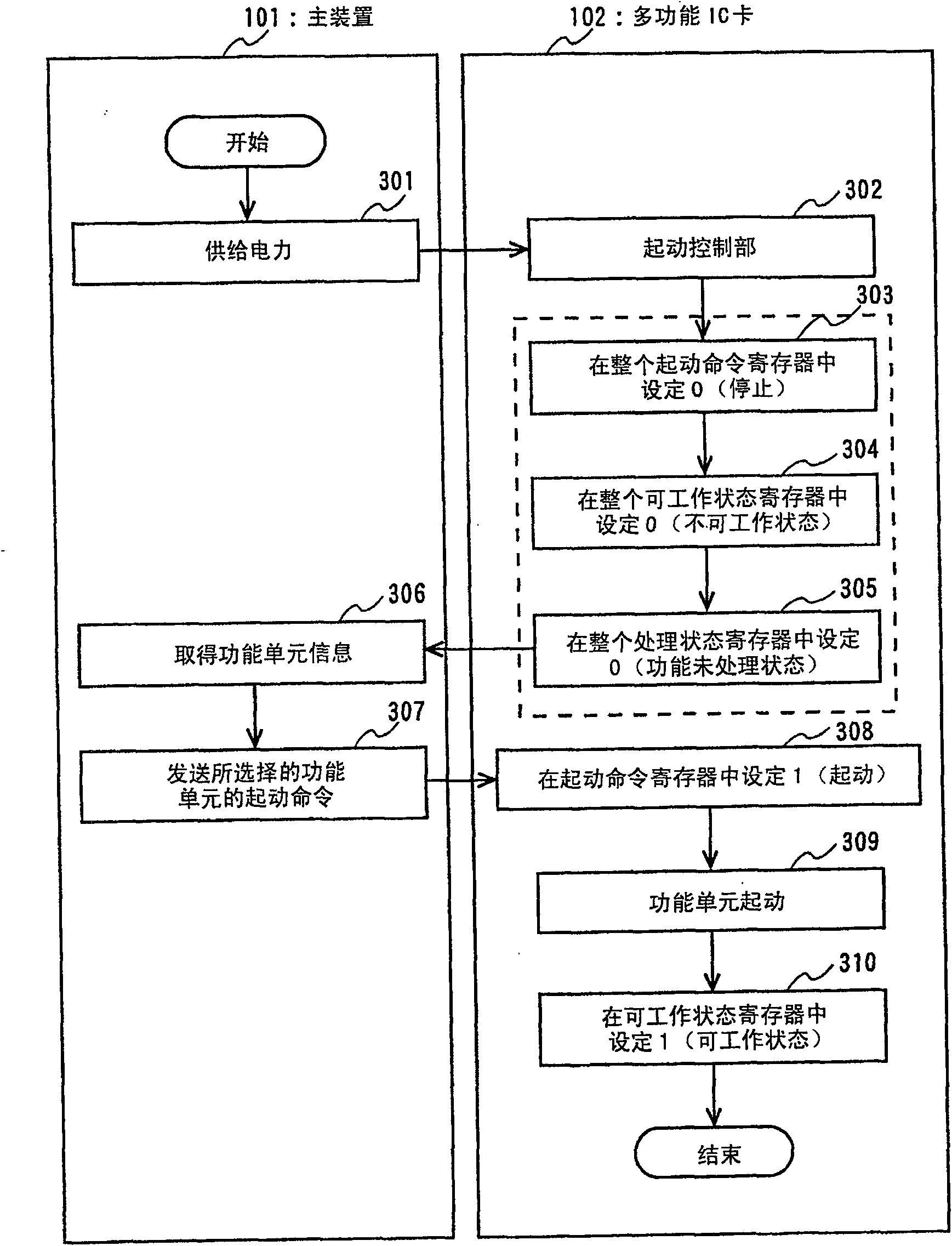

Electronic device and control method thereof

ActiveCN1879115AImplement the control methodQuickly and accuratelyResource allocationMemory record carrier reading problemsProcessor registerStatus register

An electronic device includes: a control unit having an interface unit for performing communication with an external host device and a state register group; and a plurality of function units for performing communication with the host device via the interface unit. The state register group has a plurality of state registers which are correlated to the function units, respectively, and indicate whether the corresponding function unit is operable and whether the corresponding unit is performing processing. When the control unit receives an instruction from the host device, the control unit transfers the instruction to a function unit if the instruction is for any of the function units, and transmits a state of the state register group as a response to the host device if the instruction is a read instruction of the state register group.

Owner:PANASONIC CORP

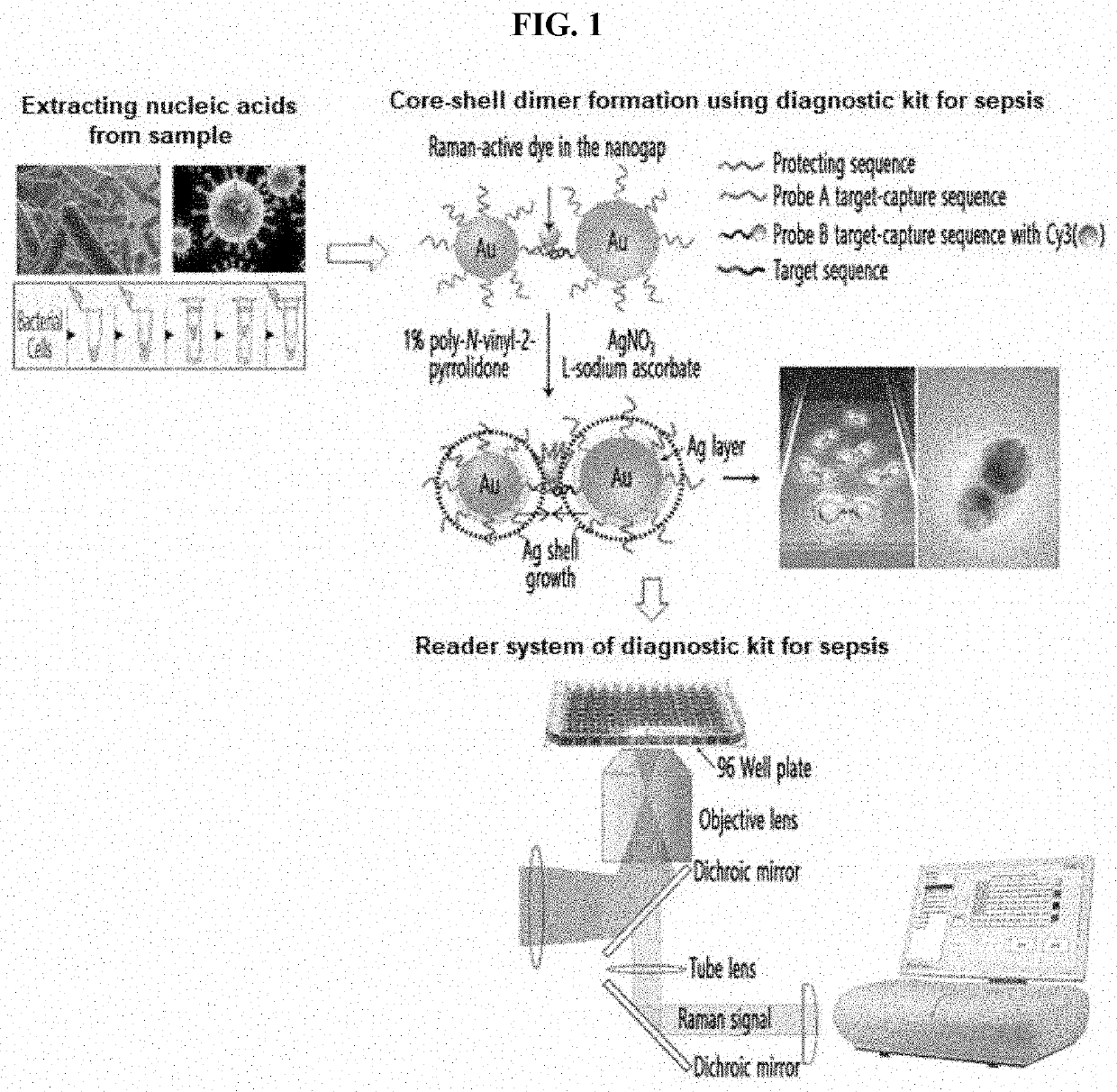

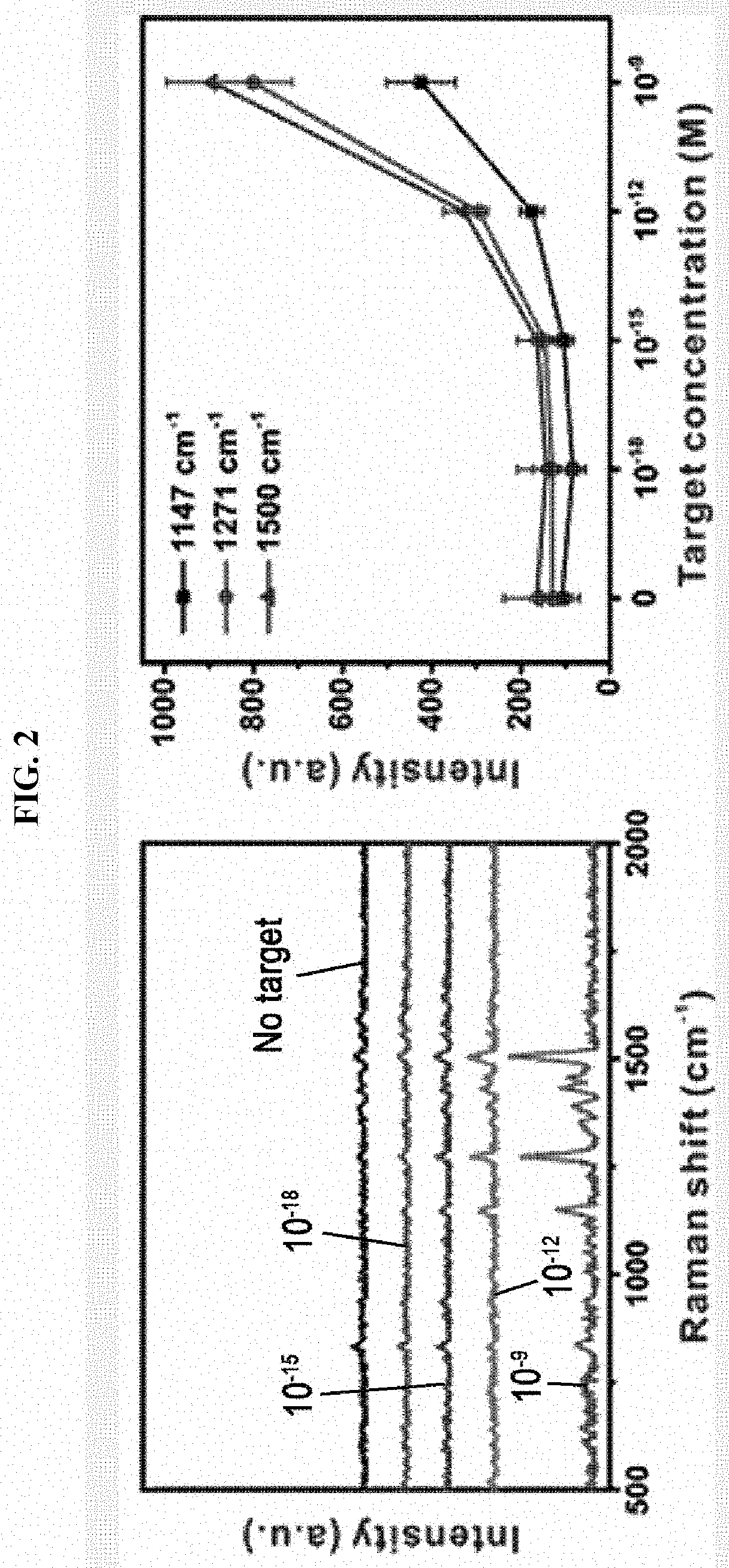

Diagnostic kit for sepsis and diagnosis method using same

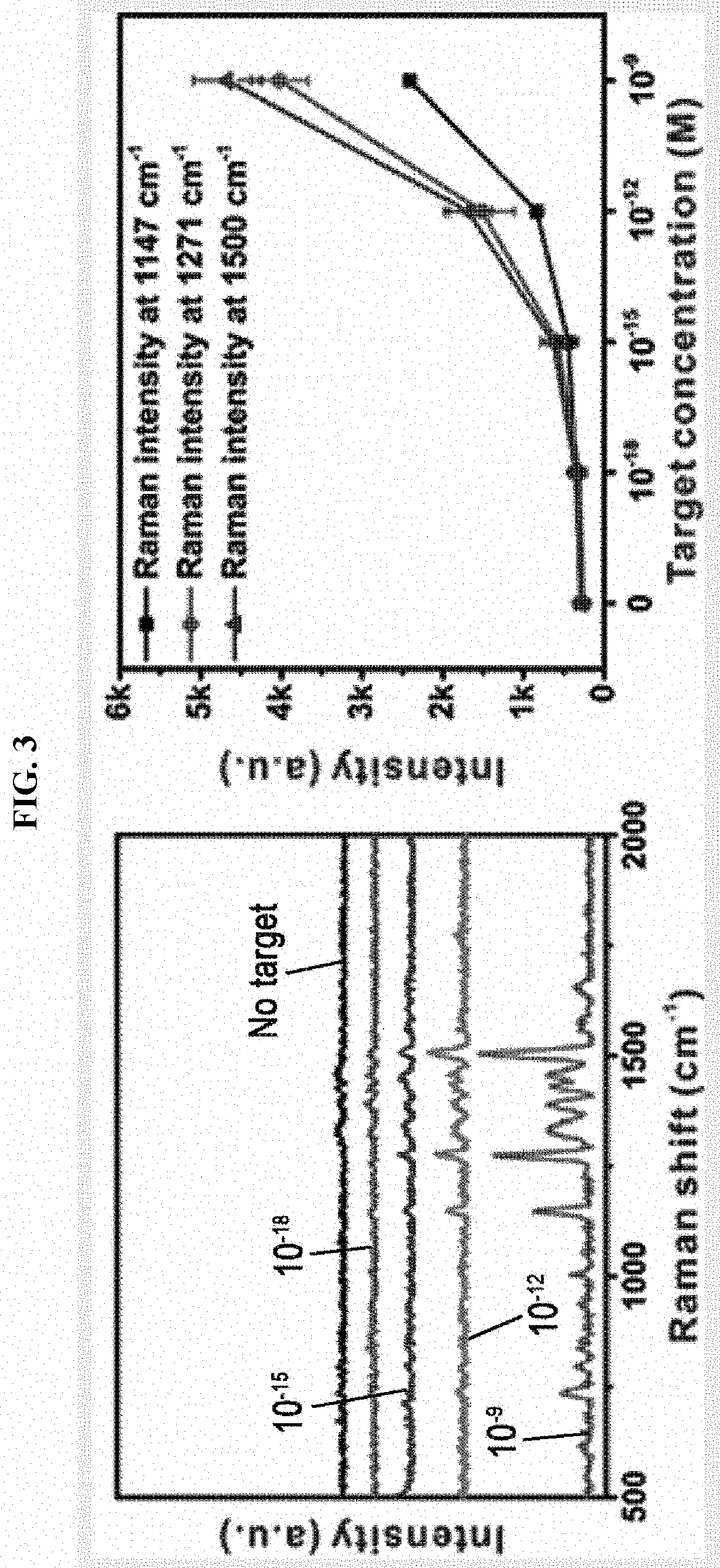

PendingUS20200217798A1Low morality rateQuickly and accuratelyMicrobiological testing/measurementRaman scatteringOligonucleotidePathogen

The present invention relates to a diagnostic kit for sepsis, comprising: a first core gold nanoparticle having a target capture oligonucleotide coupled thereto, the target capture oligonucleotide binding complementarily to a portion of a sepsis pathogen-specific genome; and a second core gold nanoparticle to which a target capture oligonucleotide having a Raman-active molecule coupled to one end thereof is coupled via the other end thereof, the target capture oligonucleotide including a sequence complementary to a portion of the sepsis pathogen-specific genome which does not overlap with, but is successive to the portion for the first gold nanoparticle, and a method for diagnosis of sepsis, using the same.

Owner:KOREA RES INST OF CHEM TECH

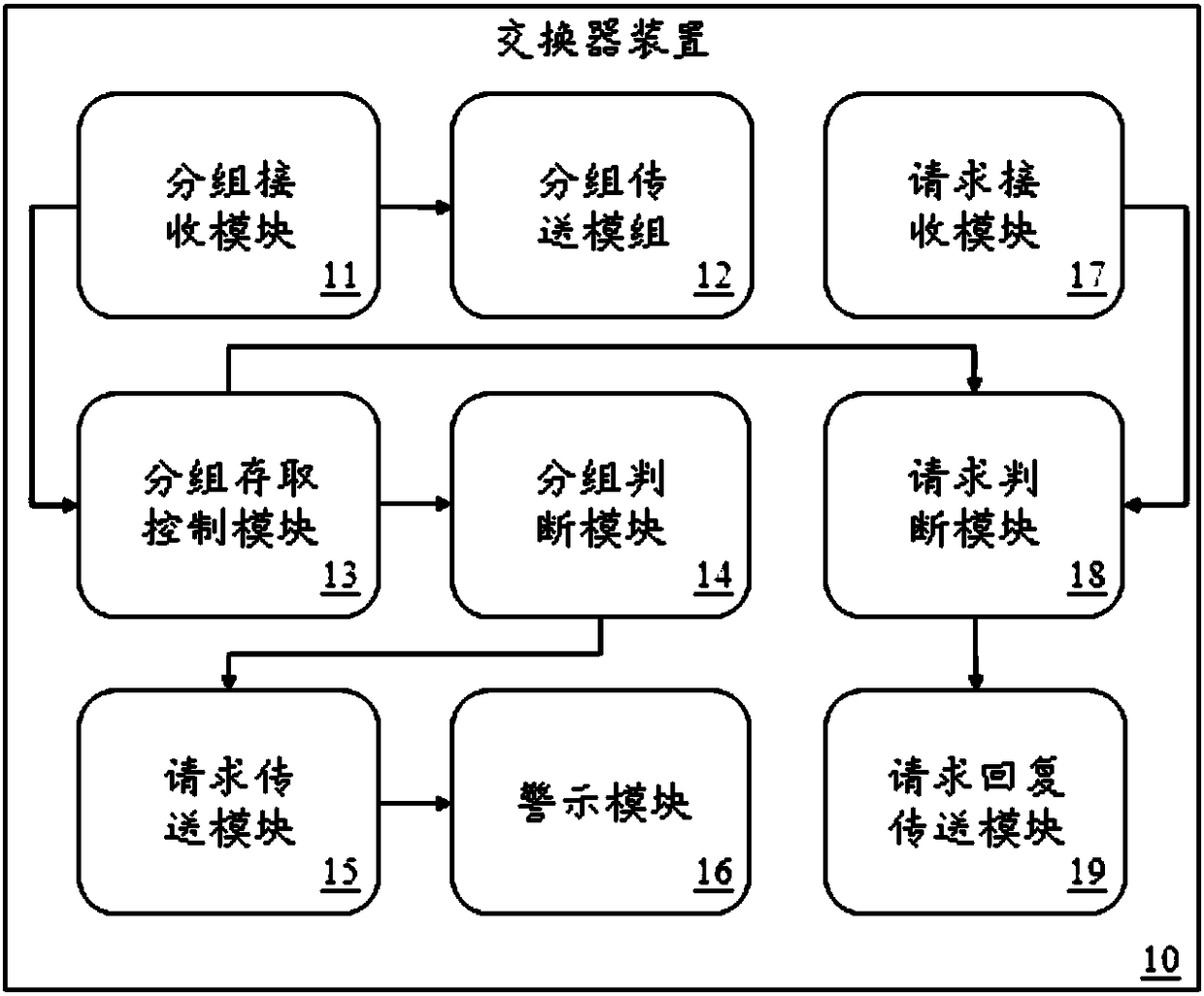

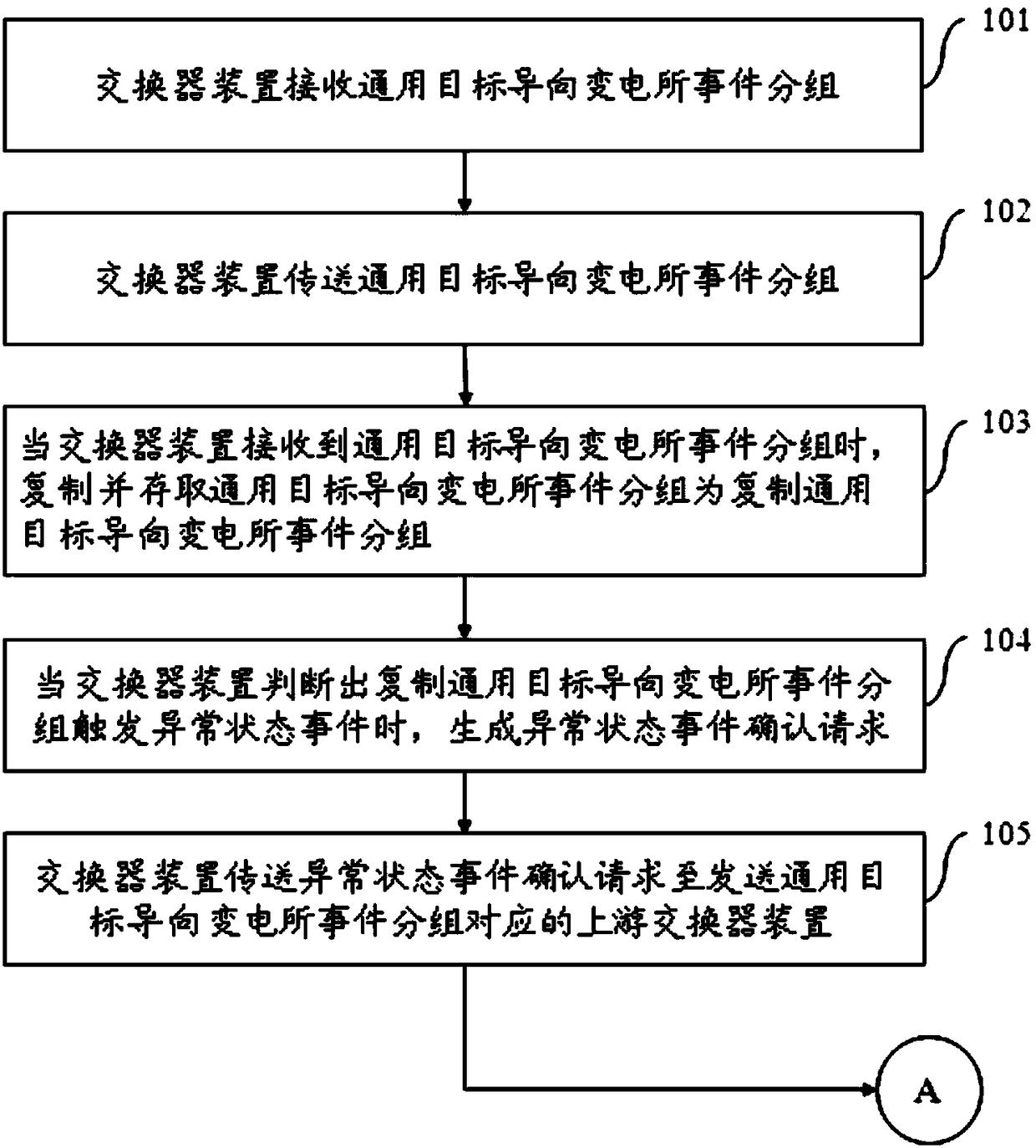

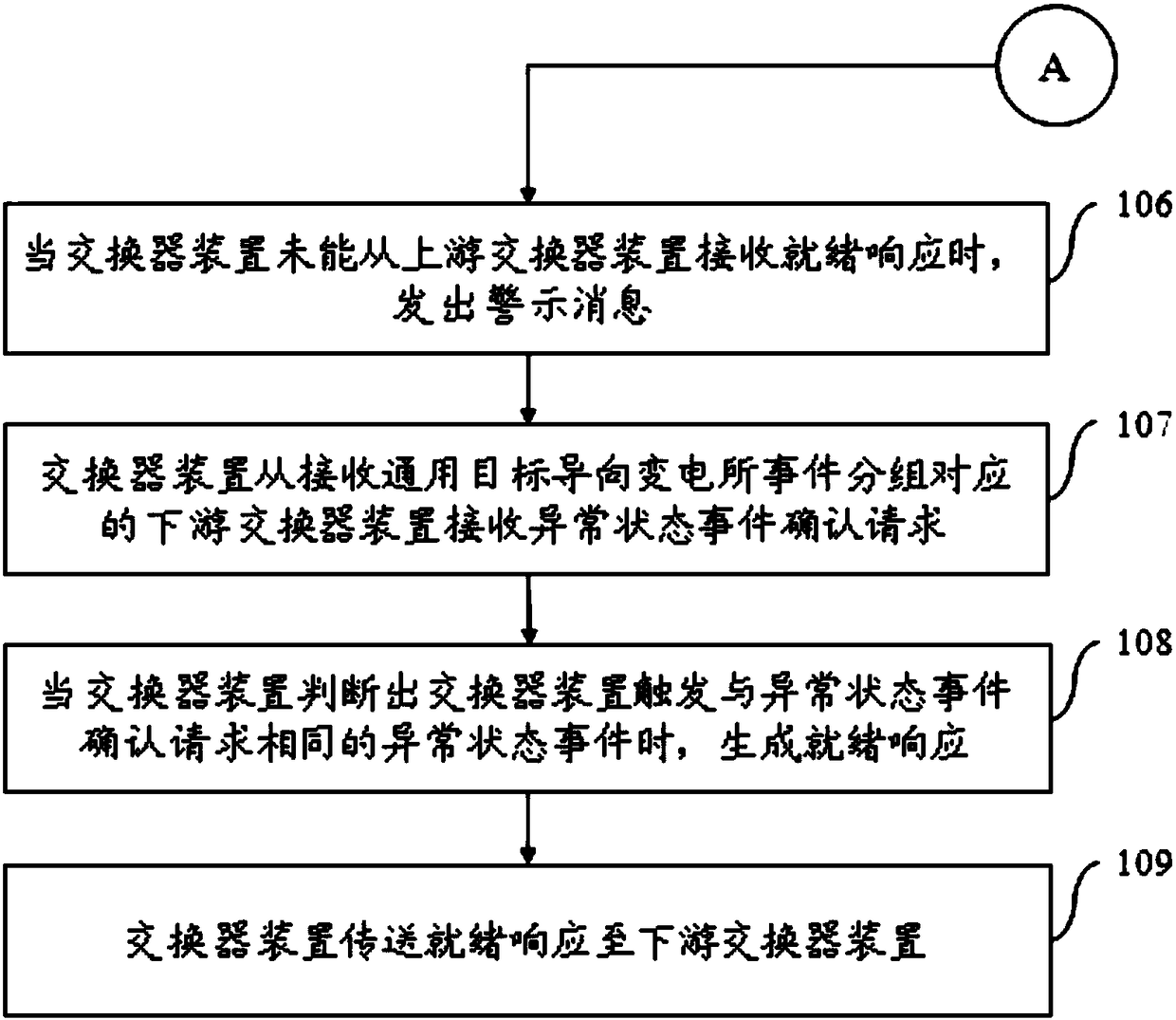

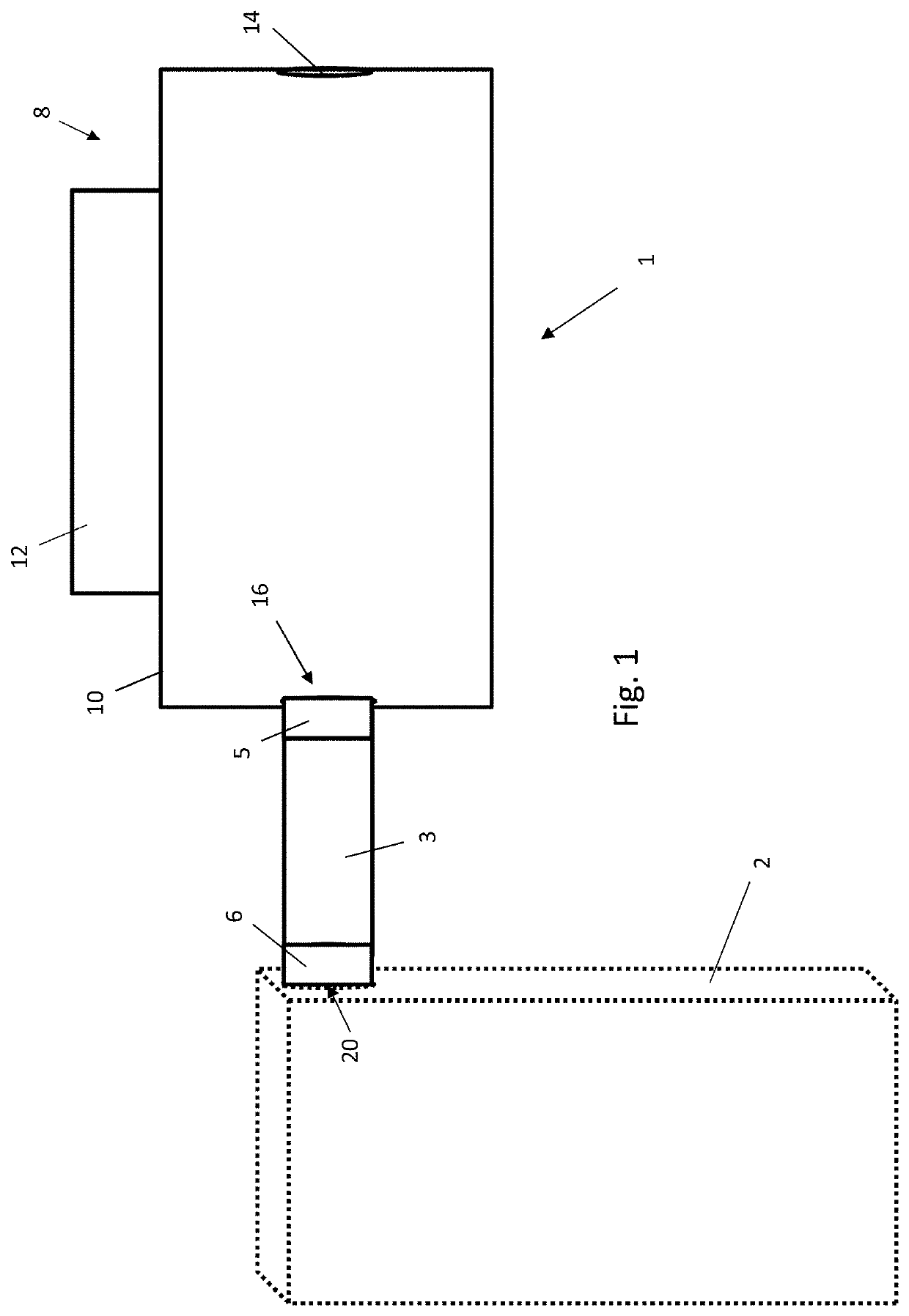

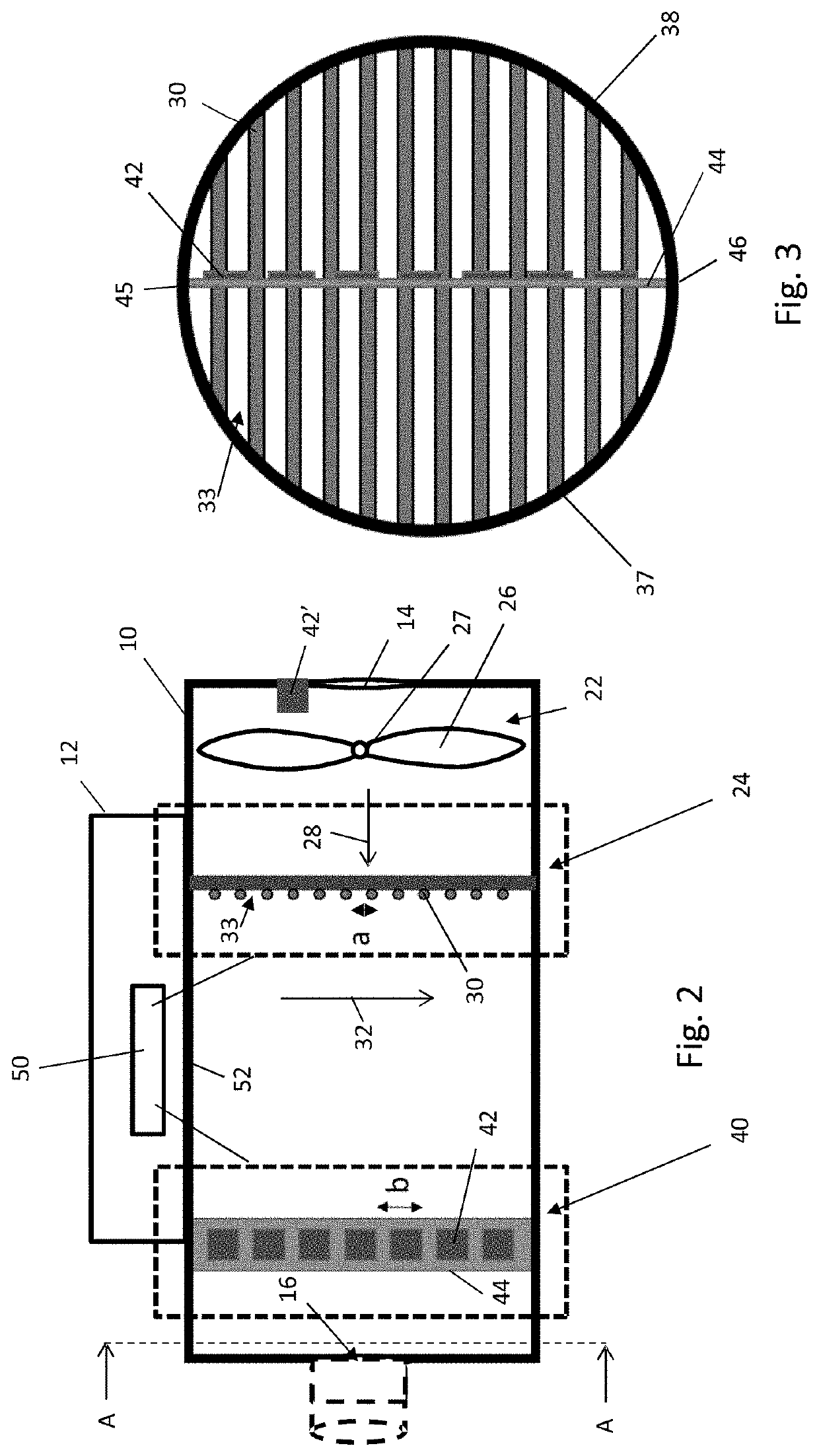

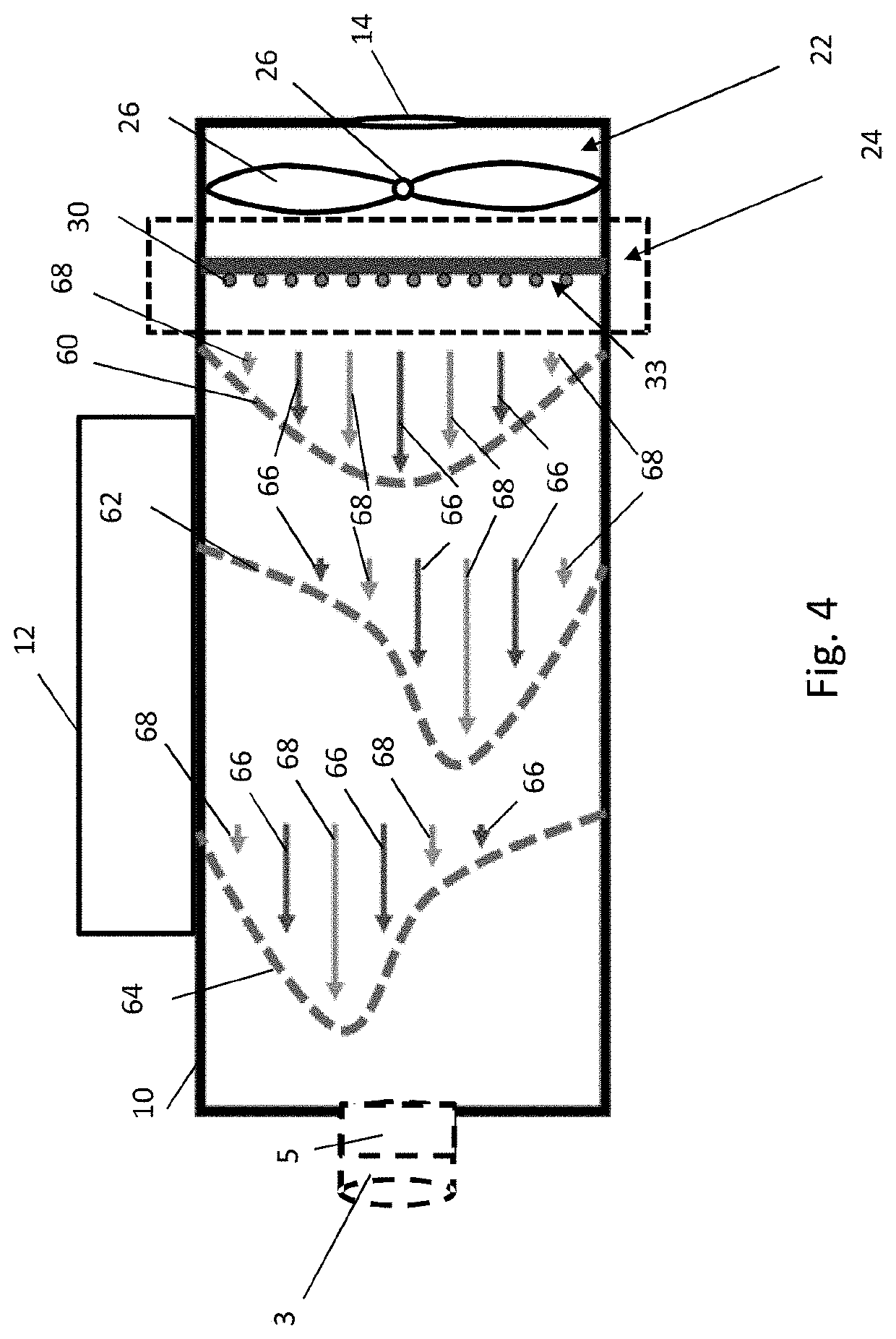

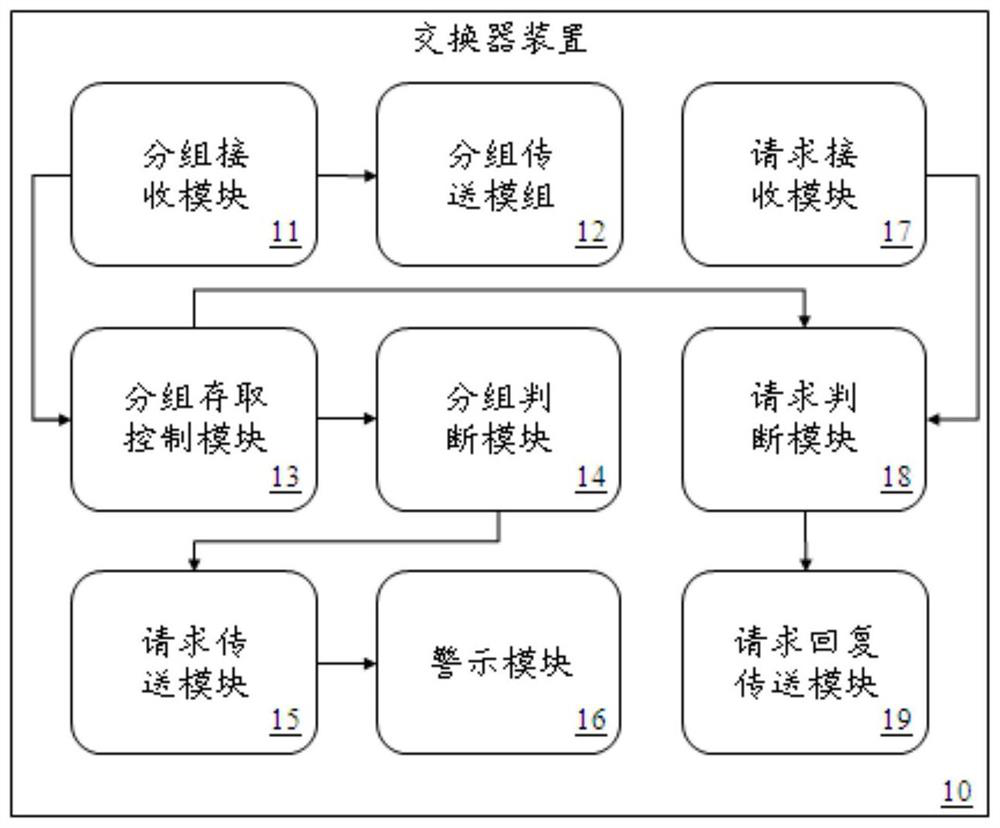

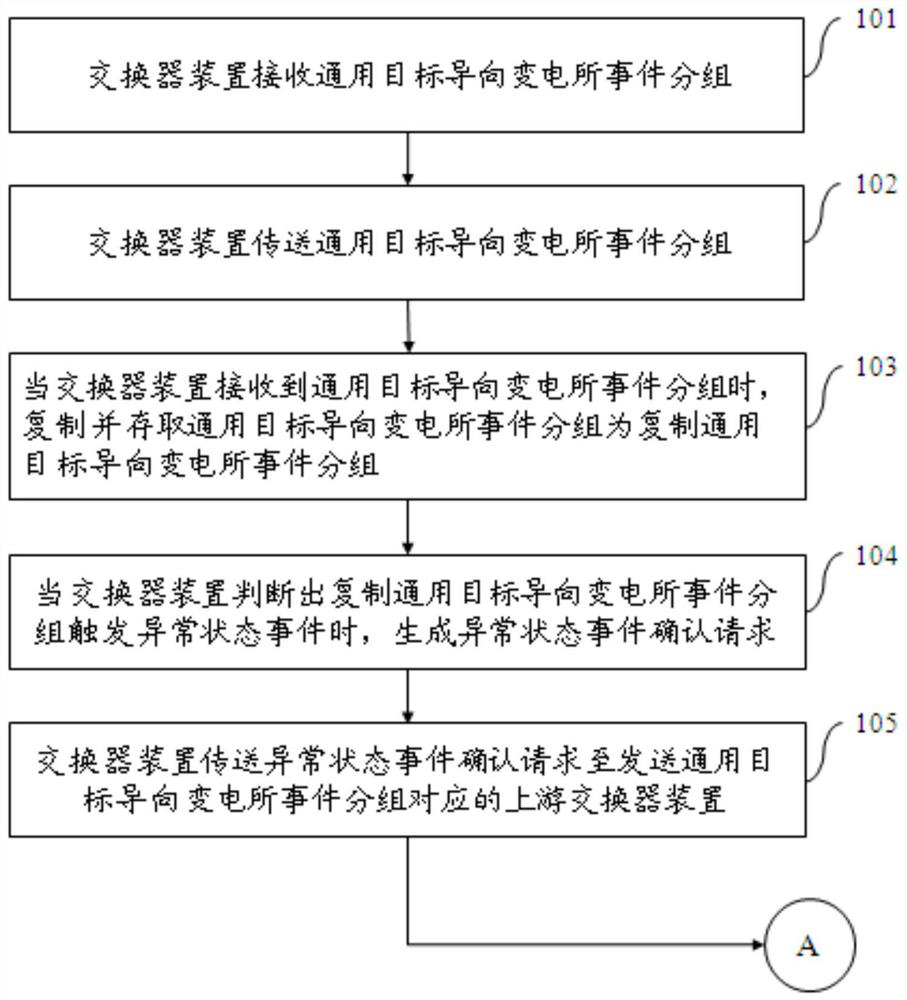

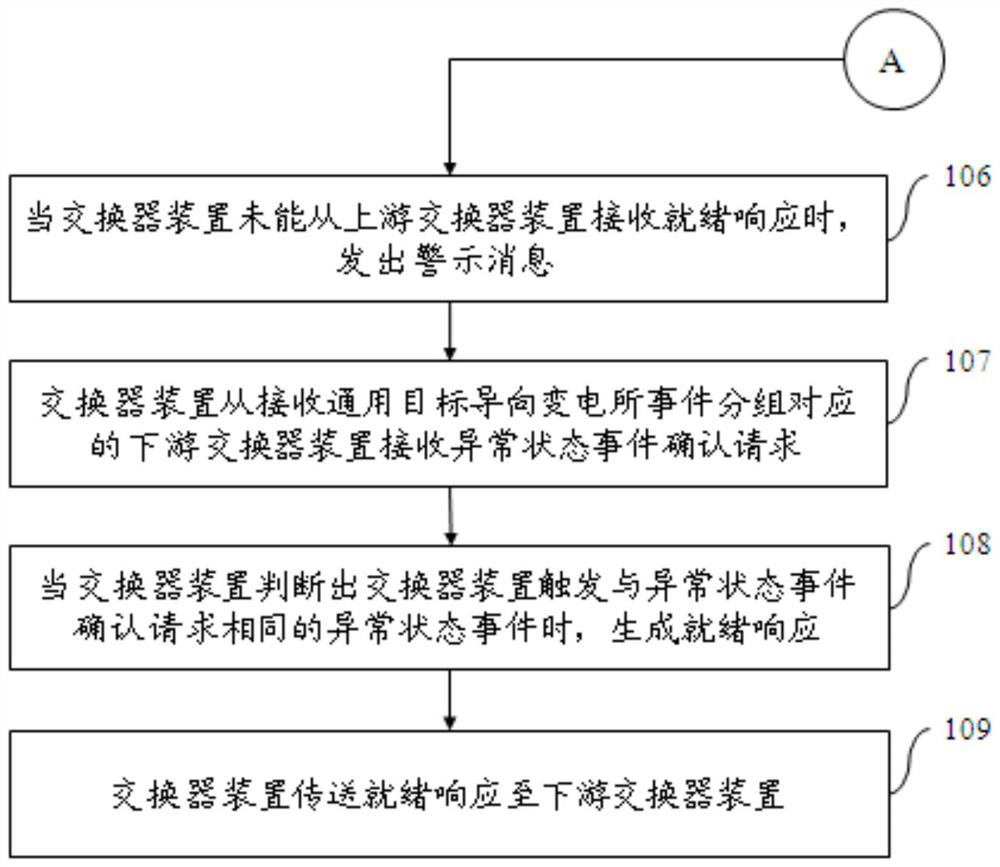

Exchanger device for transformer substation and fault warning method

ActiveCN109391484AQuickly and accuratelyPromote repairData switching networksPower substationReal-time computing

The invention relates to an exchanger device for a transformer substation and a fault warning method. The exchanger device replicates and accesses a generic object-oriented substation event packet; when the exchanger device determines that the generic object-oriented substation event packet triggers an abnormal state event, the exchanger device generates an abnormal state event confirmation request and transmits the request to a corresponding upstream exchanger device; and when the exchanger device can not receive a ready response from the upstream exchanger device, a warning message is sent out. Therefore, the exchanger device can obtain the initial triggered abnormal state event rapidly and accurately and thus maintenance is carried out conveniently.

Owner:MOXA INC

Electronic device and control method thereof

ActiveCN100517377CImplement the control methodQuickly and accuratelyResource allocationMemory record carrier reading problemsProcessor registerStatus register

An electronic device includes: a control unit having an interface unit for performing communication with an external host device and a state register group; and a plurality of function units for performing communication with the host device via the interface unit. The state register group has a plurality of state registers which are correlated to the function units, respectively, and indicate whether the corresponding function unit is operable and whether the corresponding unit is performing processing. When the control unit receives an instruction from the host device, the control unit transfers the instruction to a function unit if the instruction is for any of the function units, and transmits a state of the state register group as a response to the host device if the instruction is a read instruction of the state register group.

Owner:PANASONIC CORP

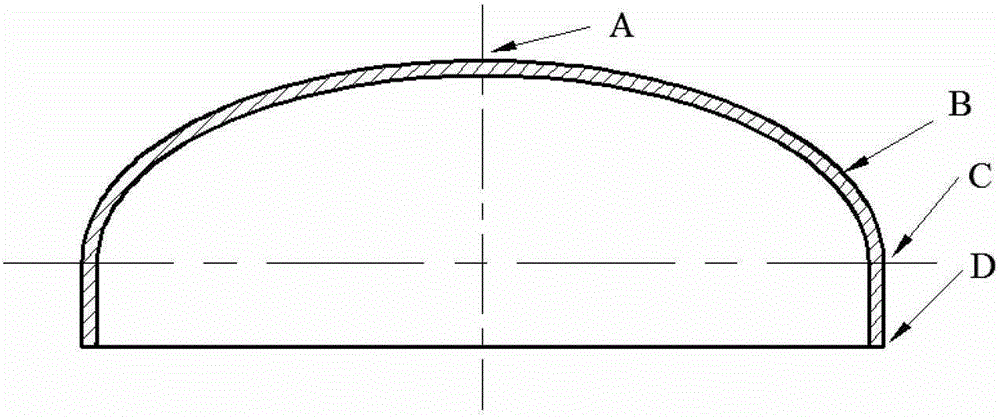

Deformation prediction method of cold stamping head based on deformation-induced martensitic transformation

ActiveCN103353296BEasy to knowQuickly and accuratelyMeasurement devicesMartensite transformationMeasuring instrument

The invention relates to quality detection techniques used for heads molded through cold pressing and aims to provide a cold pressing head deformation quantity predicating method based on deformation-induced martensite phase transformation. The deformation quantity predicating method includes specific steps of conducting a head cold pressing molding test, performing finite element simulation in a cold pressing process and creating a relation curve of the deformation quantities and the martensite phase transformation quantities of the cold pressing head; using a ferrite measuring instrument for measuring martensite phase transformation quantities of areas of the cold pressing head requiring predication respectively; and substituting the measured martensite phase transformation quantities of the different areas of the cold pressing head into the obtained relation curve of the deformation quantities and the martensite phase transformation quantities of the corresponding areas respectively, so that the deformation quantities of the areas of the cold pressing head are obtained. By adopting the deformation quantity predicating method provided by the invention, curves of the deformation quantities of transition segments, straight sections and shell parts of different austenitic stainless steel heads can be determined and the plastic deformation quantities of the heads can be obtained conveniently, quickly and accurately by using the ferrite measuring instrument. The deformation quantity predicating method is very suitable for applying to the field of engineering.

Owner:ZHEJIANG UNIV

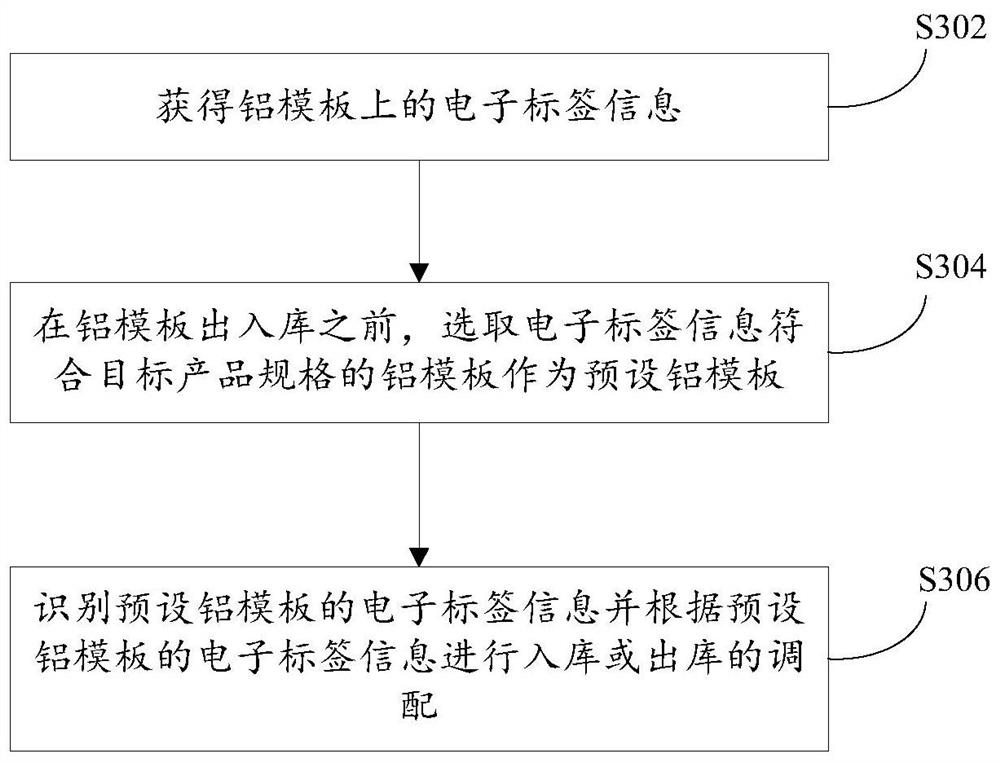

Method and system for deploying metal building material formwork into and out of storage

ActiveCN109325558BReduce storage timeQuickly and accuratelyCo-operative working arrangementsLogisticsElectromagnetic couplingSoftware engineering

The invention discloses a method and a system for deploying metal building material formwork into and out of a warehouse. Among them, the system includes: electronic tags, radio frequency signal readers, antennas, personal computer terminals and back-end data processing units; electronic tags are set on each metal building material template, and the electronic tag is used to correspond to the specifications and current position of the metal building material template ; The radio frequency signal reader is used to identify the electronic tag information, and the electronic tag and the radio frequency signal reader are electromagnetically coupled through the antenna to realize long-distance information identification; The metal building material template is used as a preset metal building material template, and the preset metal building material template forms a model of the target product; the back-end data processing unit is used for storage or delivery deployment according to the electronic label information of the preset metal building material template. The invention solves the technical problems of slow deployment template speed and high error rate existing in the prior art.

Owner:UNIV OF SCI & TECH BEIJING

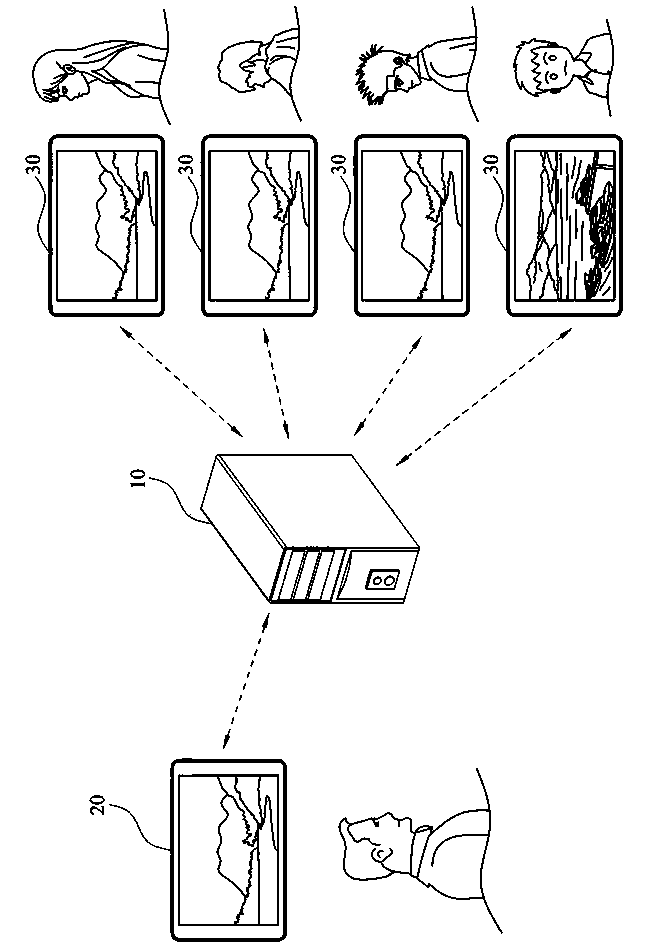

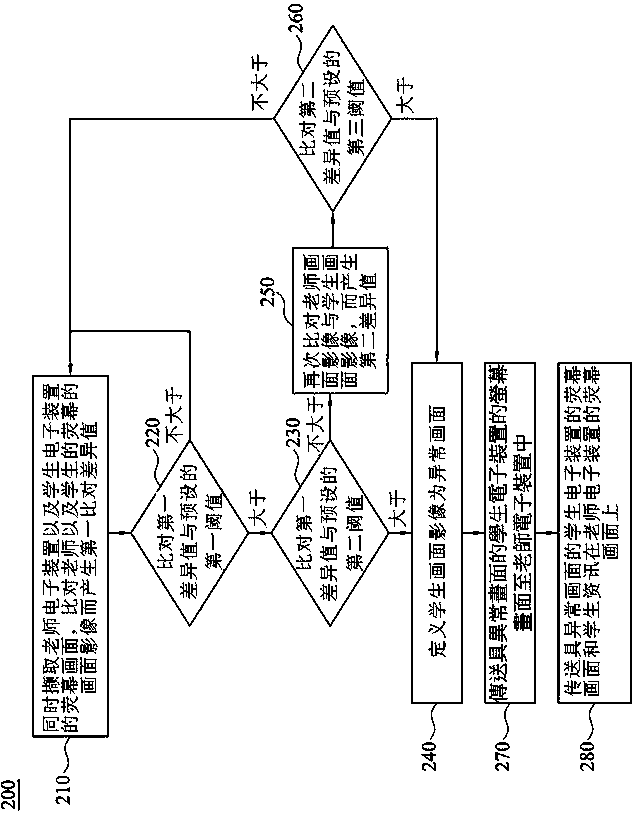

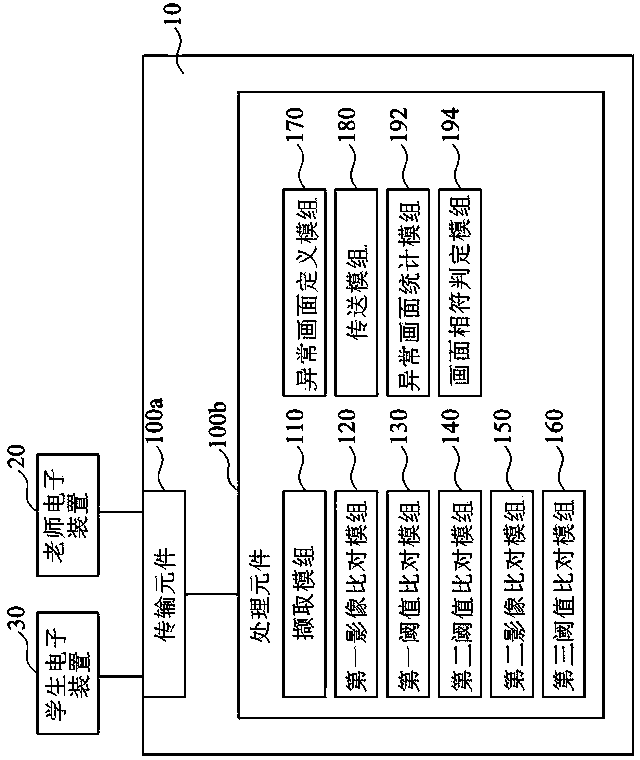

Digital teaching system and screen monitoring method thereof

Provided is a screen monitoring method. The screen monitoring method is applied to a digital teaching system. The method comprises that a screen picture of a teacher electronic device and a screen picture of a student electronic device are captured at the same time. Through a first image comparison method, the teacher picture and the student picture are compared to generate a first difference value. When the first difference value is greater than a first threshold value, the first difference value and a second threshold value are compared. When the first difference value is not greater than the second threshold value, through a second image comparison method, the teacher picture and the student picture are compared to generate a second difference value. When the first difference value is greater than the second threshold value or the second difference value is greater than a third threshold value, the screen picture, provided with an abnormal image, of the student electronic device is conveyed to the teacher electronic device.

Owner:CPT TECH GRP +1

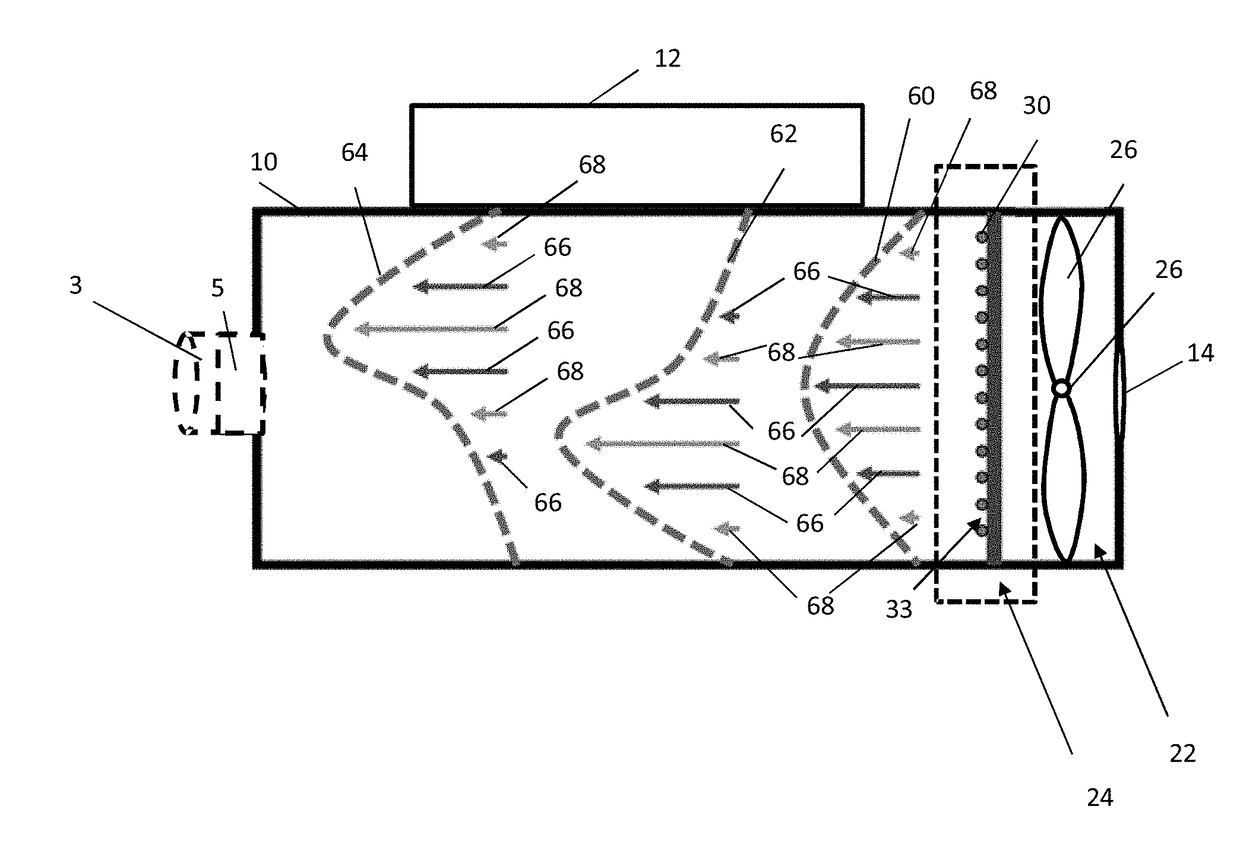

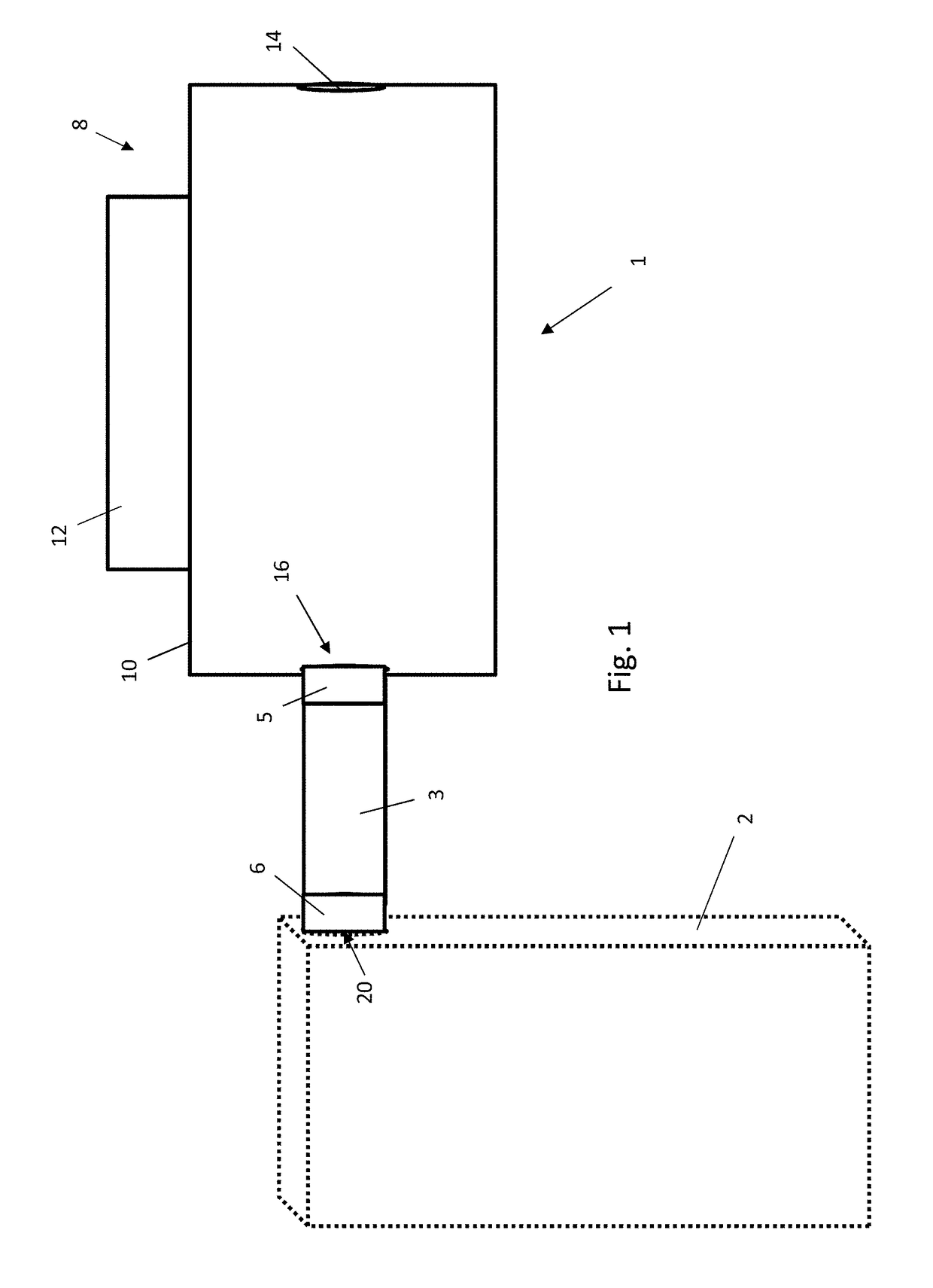

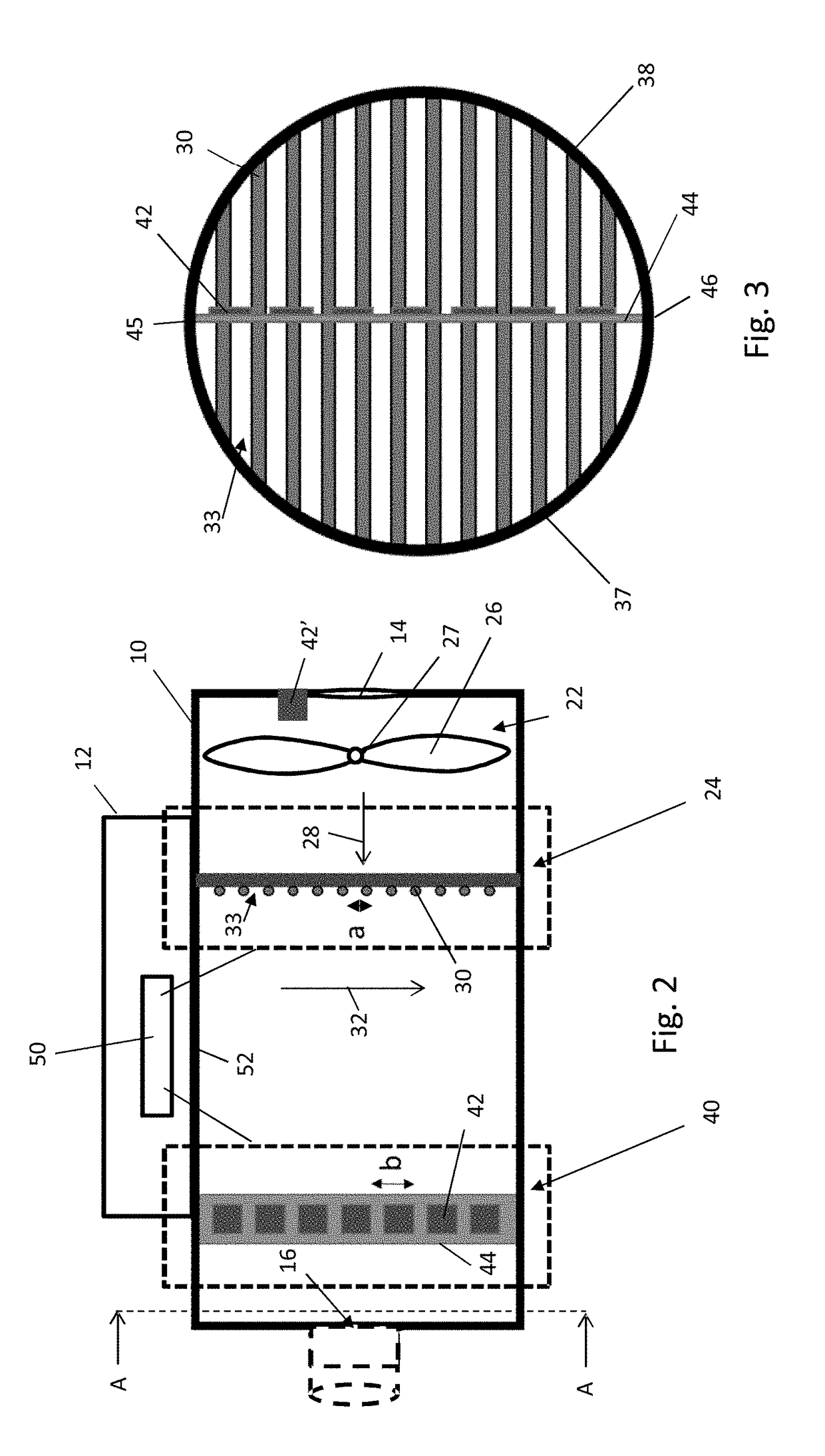

Fluid warming apparatus

ActiveUS20180008456A1Maintain accuracyAccurate predictionElectric heatingTherapeutic coolingTwo temperatureEngineering

Owner:THE SURGICAL INT

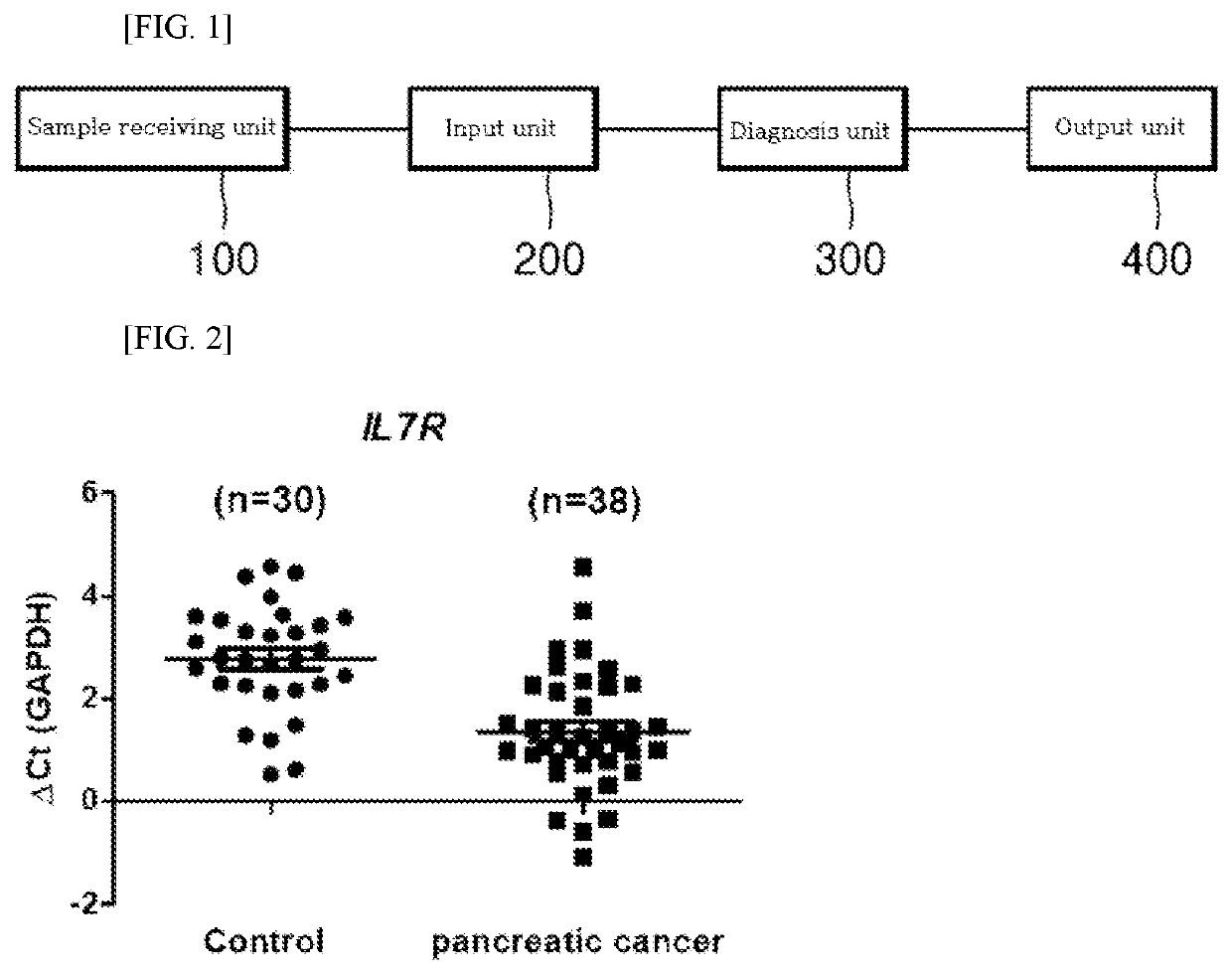

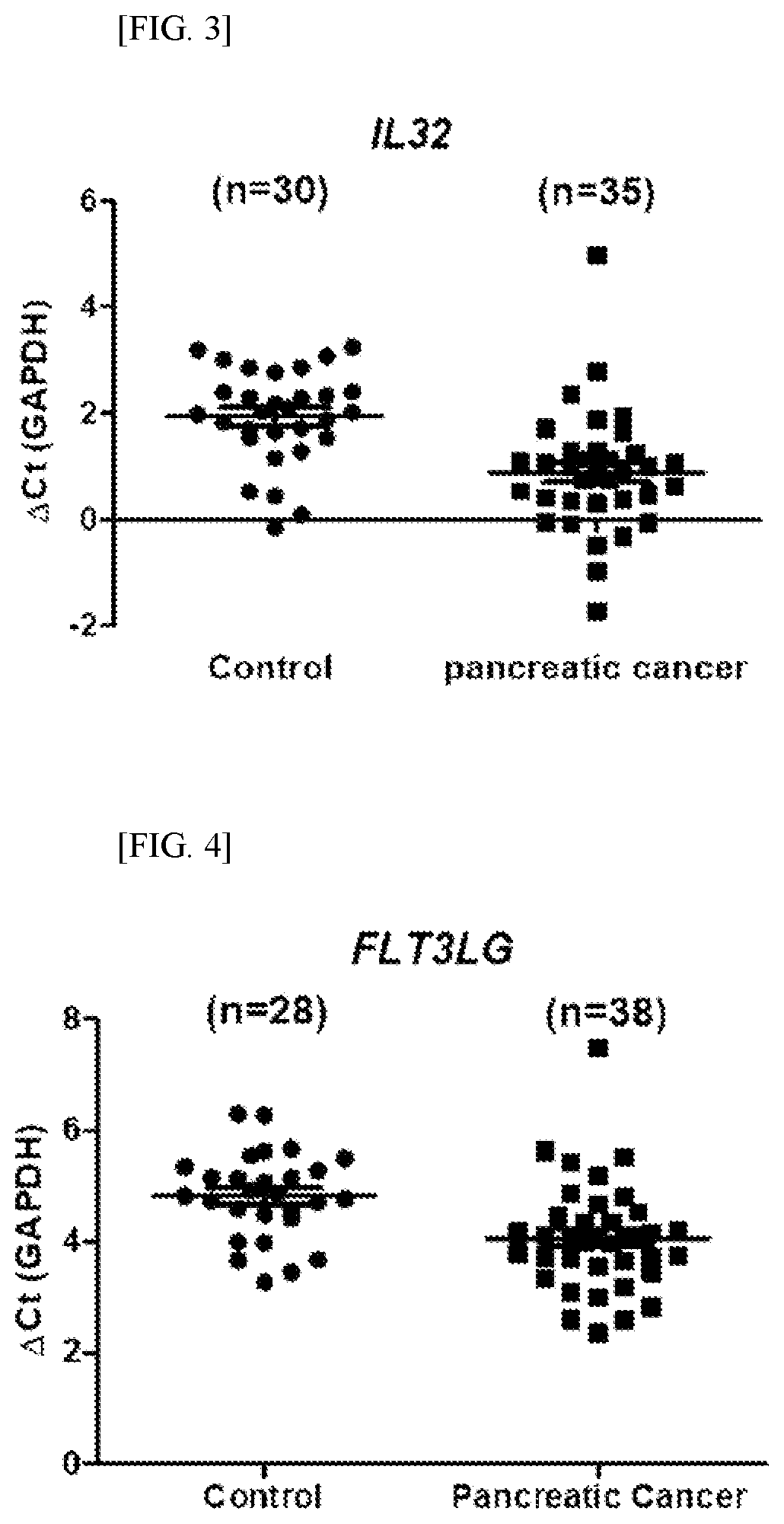

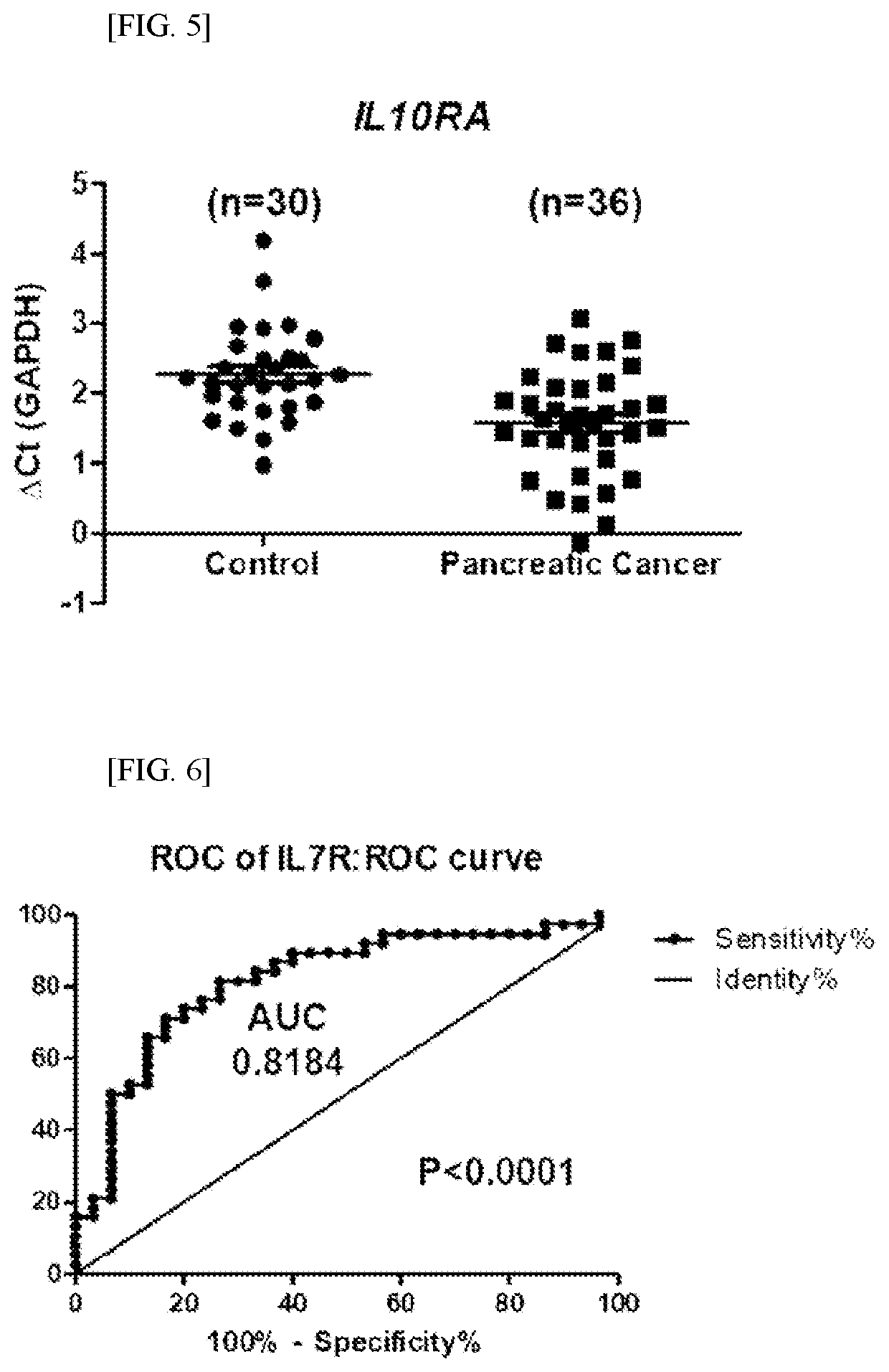

Composition for cancer diagnosis

PendingUS20220326243A1Quickly and accuratelyEarly diagnosisMicrobiological testing/measurementBiological material analysisCancers diagnosisCancer research

The present disclosure relates to a composition capable of diagnosing cancer, specifically pancreatic cancer or the like, a diagnostic kit comprising the same, and a method of providing information for diagnosis using the composition. Also, the present disclosure relates to a pharmaceutical composition capable of preventing or treating pancreatic cancer.

Owner:ACURASYSBIO CO LTD

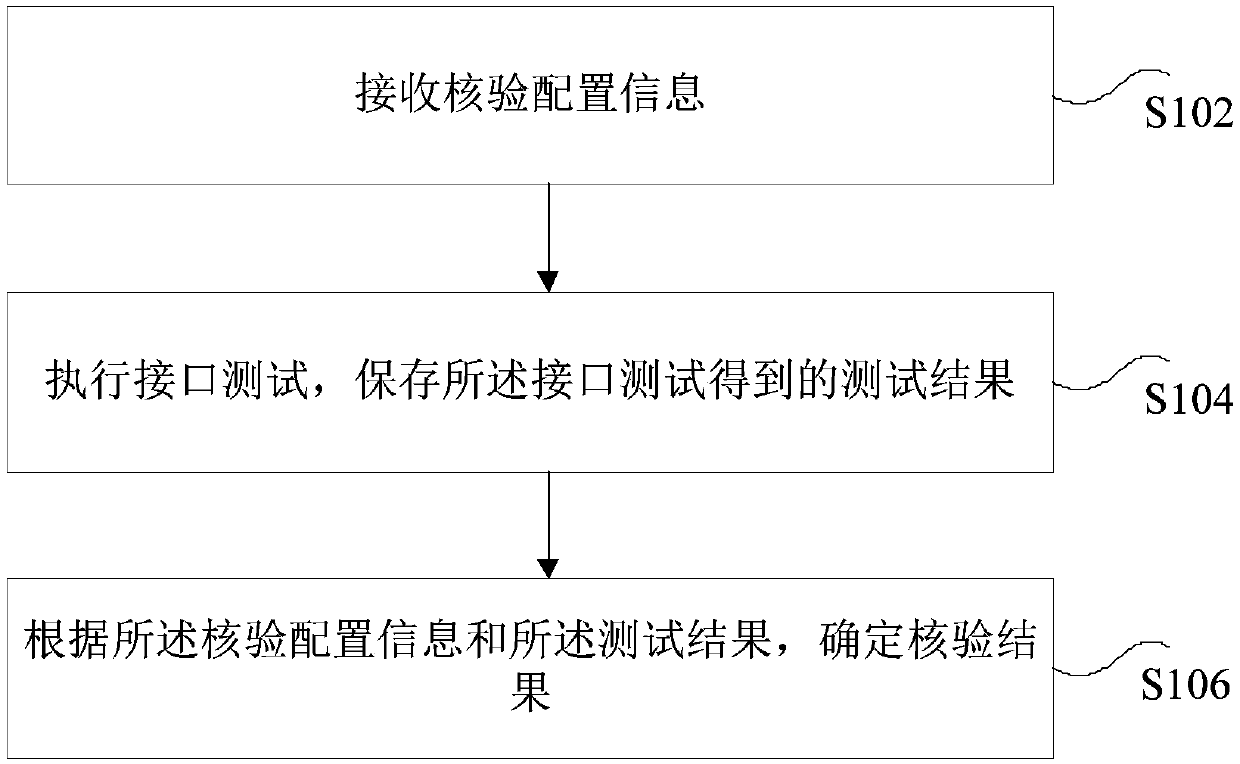

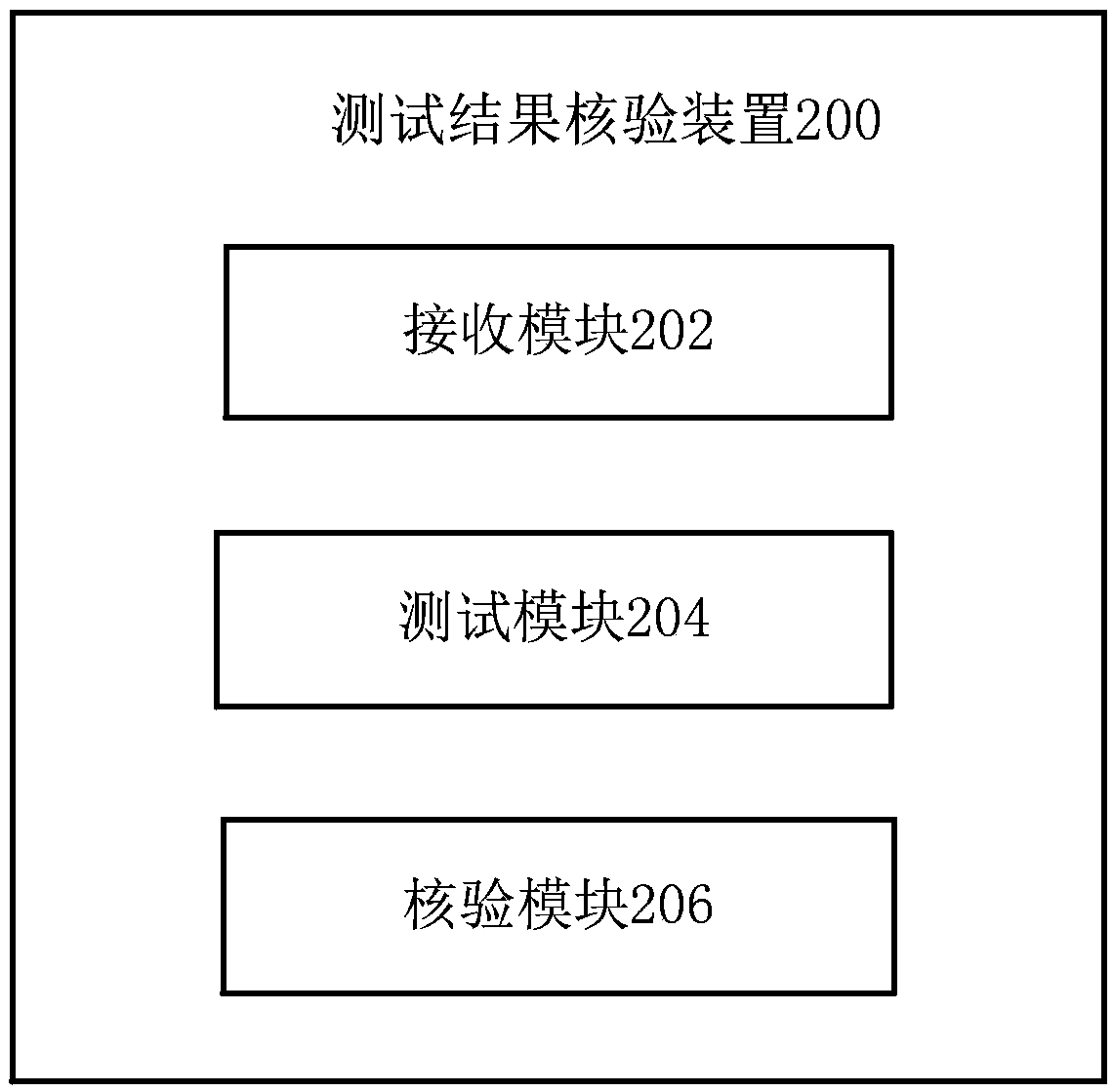

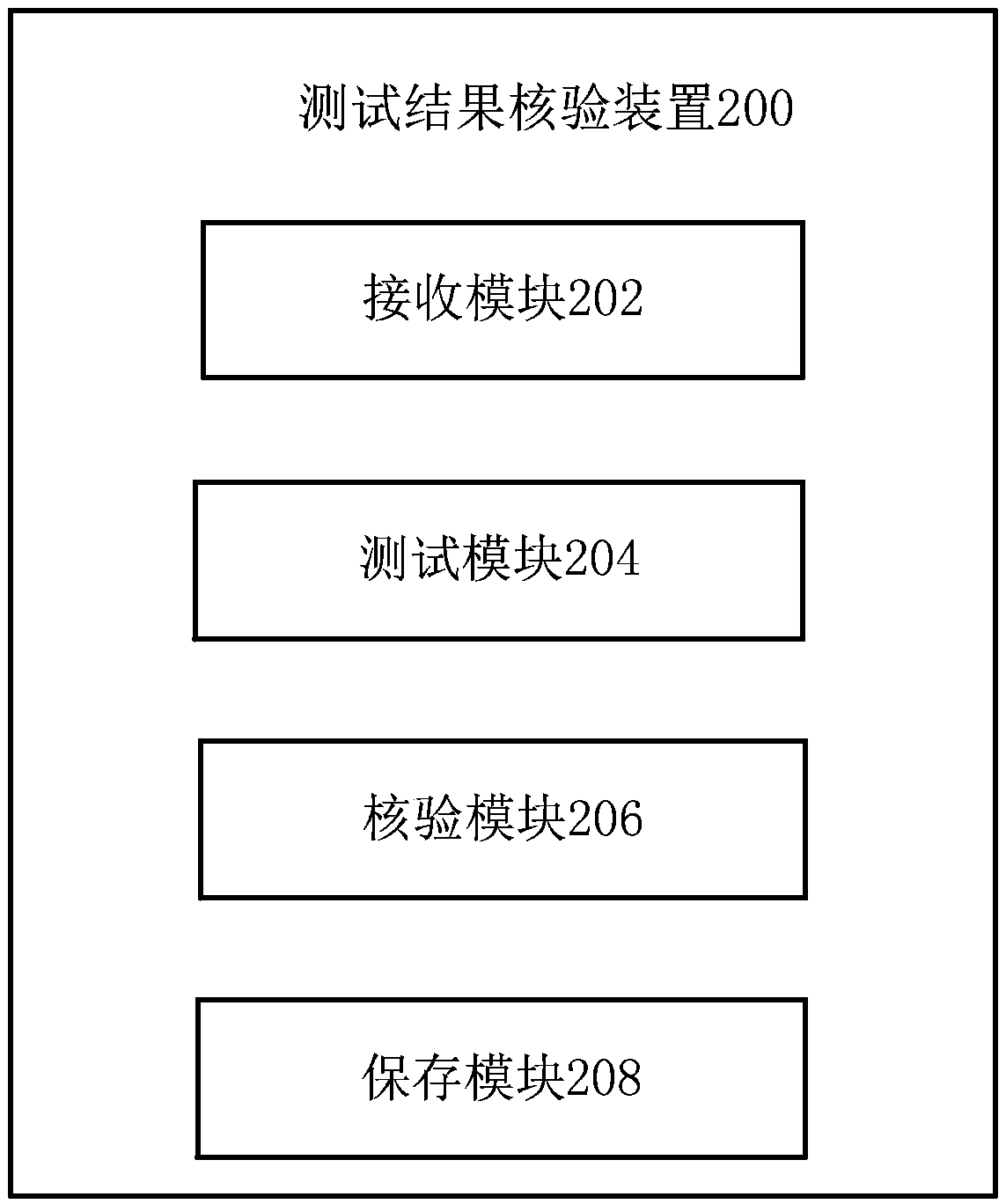

Test result verification method, device and equipment and computer readable storage medium

PendingCN109684193AAvoid error rateQuickly and accuratelySoftware testing/debuggingComputer engineeringAPI testing

The invention discloses a test result verification method, device and equipment and a computer readable storage medium. The method comprises the following steps: receiving verification configuration information; Executing an interface test, and storing a test result obtained by the interface test; And determining a verification result according to the verification configuration information and thetest result. According to the scheme, the problems of low error rate and low verification speed in the manual verification process are solved, and the technical effect of quickly and accurately obtaining the verification result is achieved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

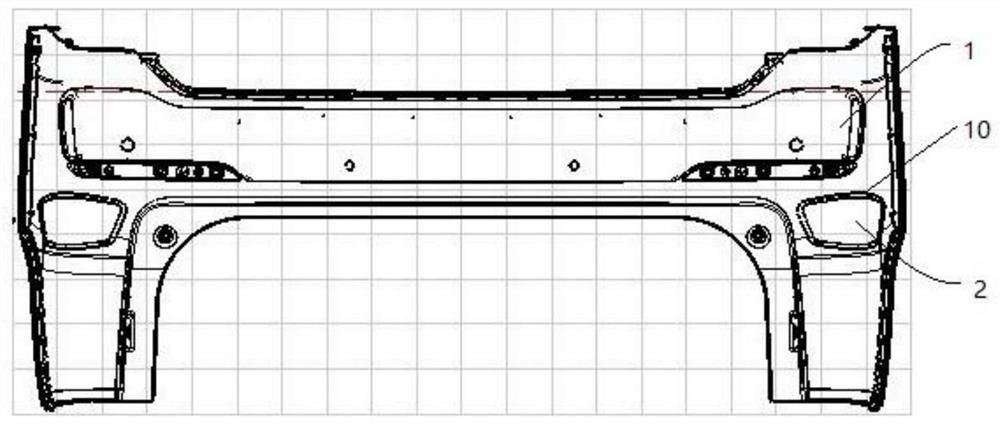

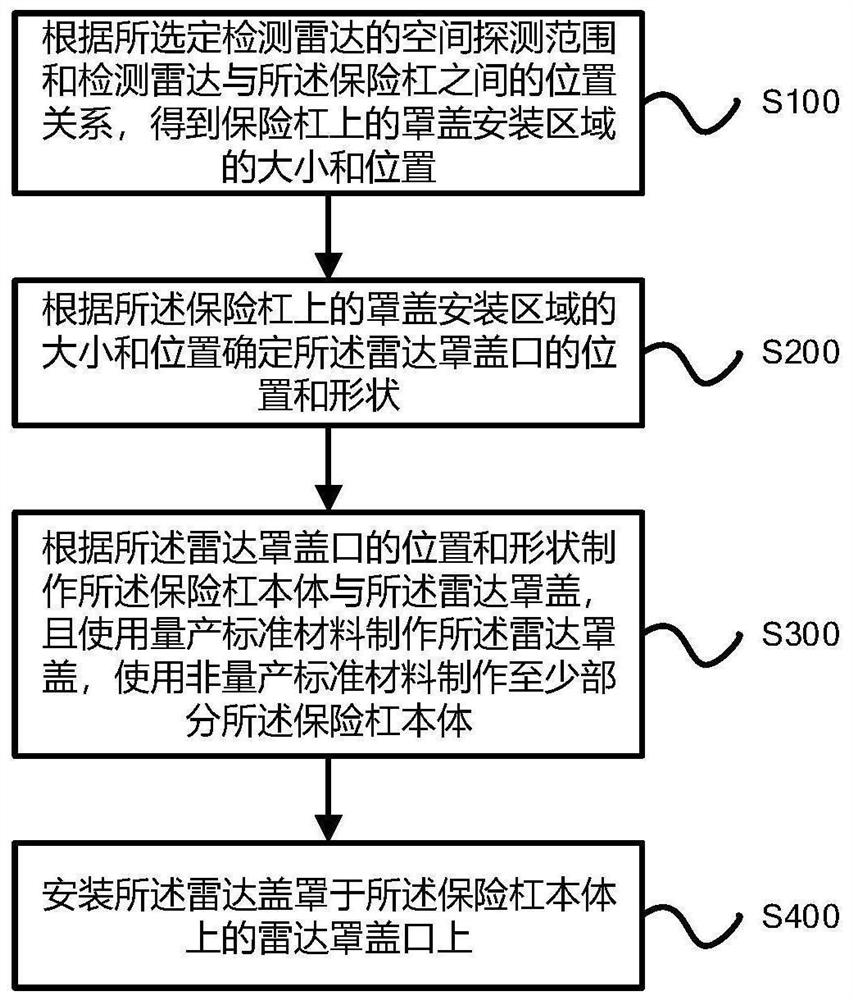

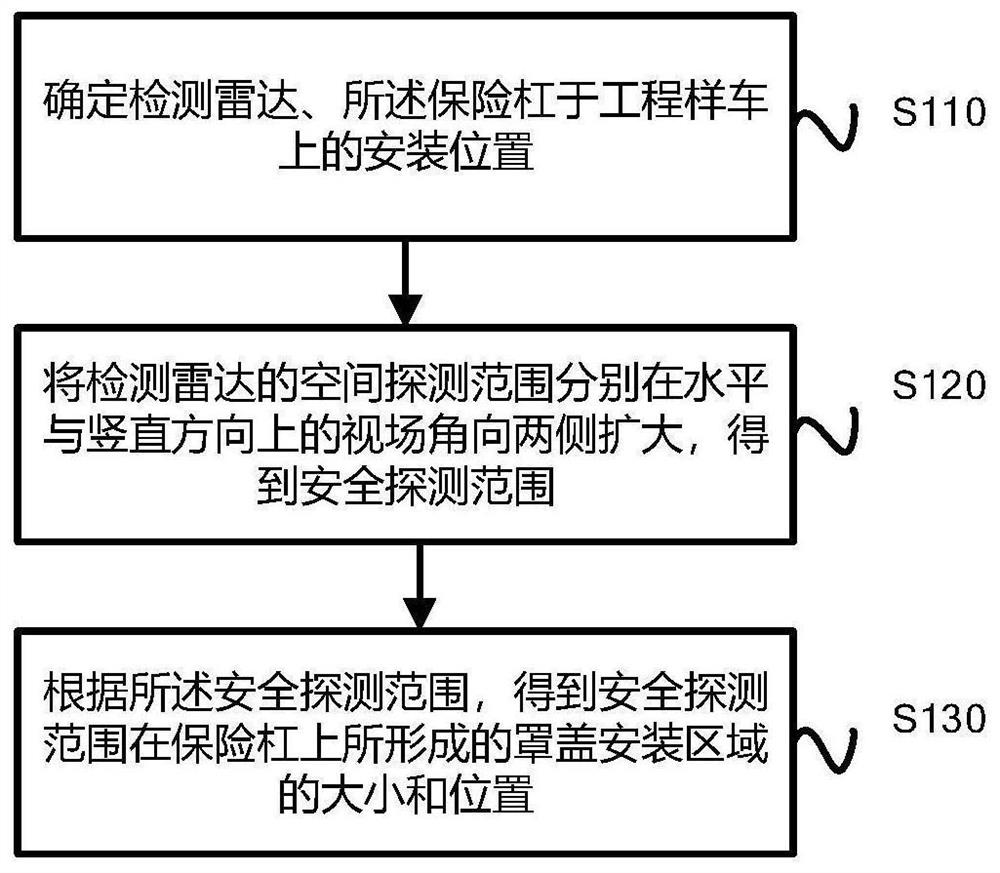

Bumper for radar detection and calibration, preparation method thereof and radar detection and calibration method

PendingCN113885001AReduce manufacturing difficultyReduce material costsWave based measurement systemsRadar detectionMechanical engineering

The invention relates to a bumper for radar detection and calibration, a preparation method of the bumper and a radar detection and calibration method, a radar detection part is arranged on the bumper corresponding to the space detection range of a detection radar, the radar detection part is made of a mass production standard material, and in the structure outside the radar detection part of the bumper, the material is at least partially different from the mass-production standard material. The radar detection part corresponding to the detection range of the detection radar is made of the mass-production standard material, so that the detection radar can smoothly carry out the detection and calibration process, and meanwhile, the structure, except for the radar detection part, of the bumper is made of the non-mass-production standard material, so that the manufacturing difficulty and the material cost of the bumper are effectively reduced. According to the technical scheme, the bumper is short in manufacturing period and low in machining cost, and finally functional verification and calibration of relevant parameters of a detection radar on an engineering sample vehicle can be completed through cooperation of the low cost and the short period.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Fluid warming apparatus

ActiveUS11147707B2Accurate predictionPrecise regulationElectric heatingTherapeutic coolingThermodynamicsEngineering

Owner:THE SURGICAL INT

Switcher device and fault warning method suitable for substations

ActiveCN109391484BQuickly and accuratelyPromote repairData switching networksEmbedded systemPower substation

A switch device and fault warning method suitable for substations. The switch device copies and accesses the general purpose-oriented substation event grouping. When the switch device judges that the general purpose-oriented substation event group triggers an abnormal state event, the switching The switch device generates an abnormal state event confirmation request and transmits it to the corresponding upstream switch device. When the switch device fails to receive a ready response from the upstream switch device, it sends a warning message, so that the initial trigger abnormality can be quickly and accurately known The switch device for status events for technical efficiency in maintenance.

Owner:MOXA INC

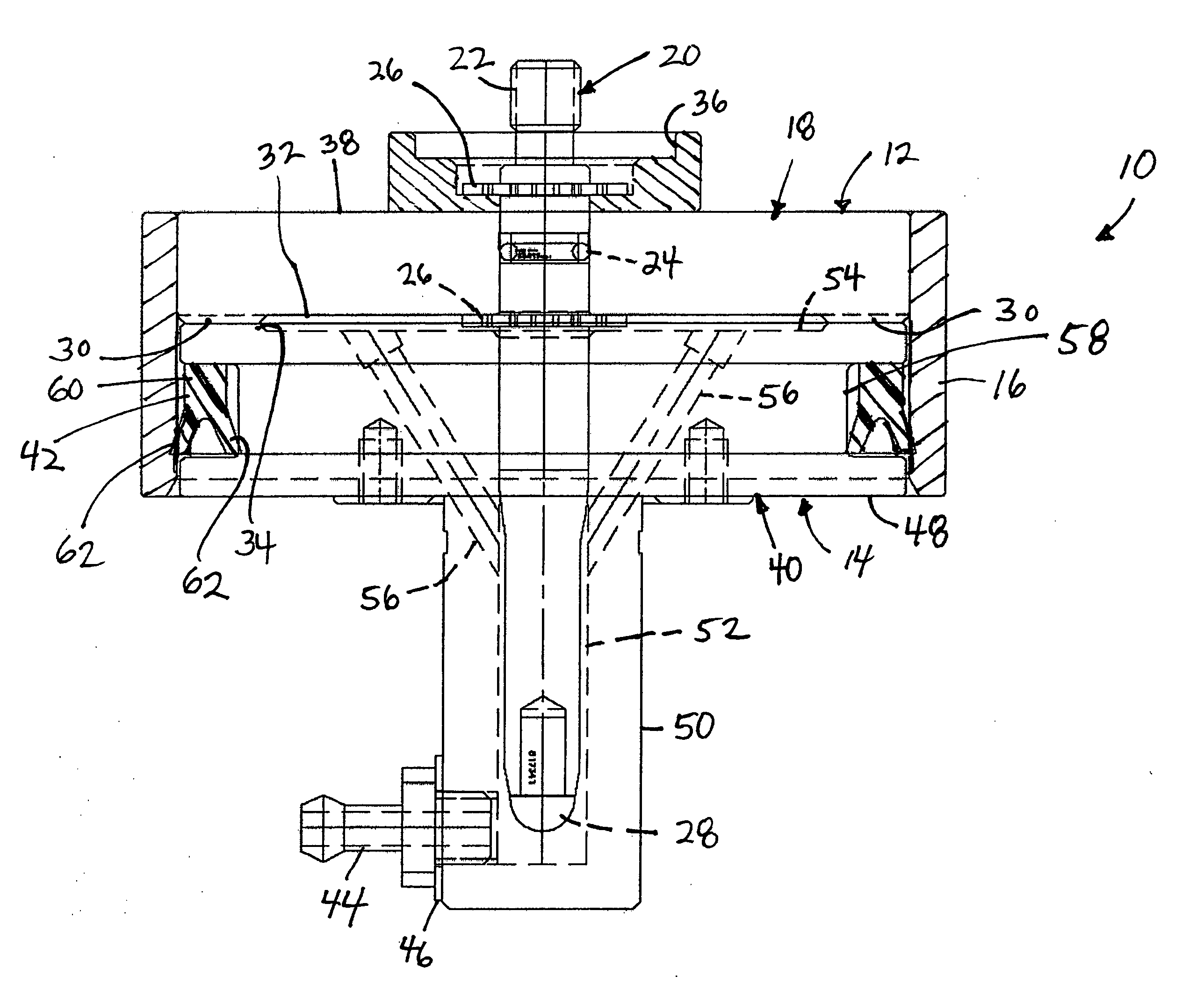

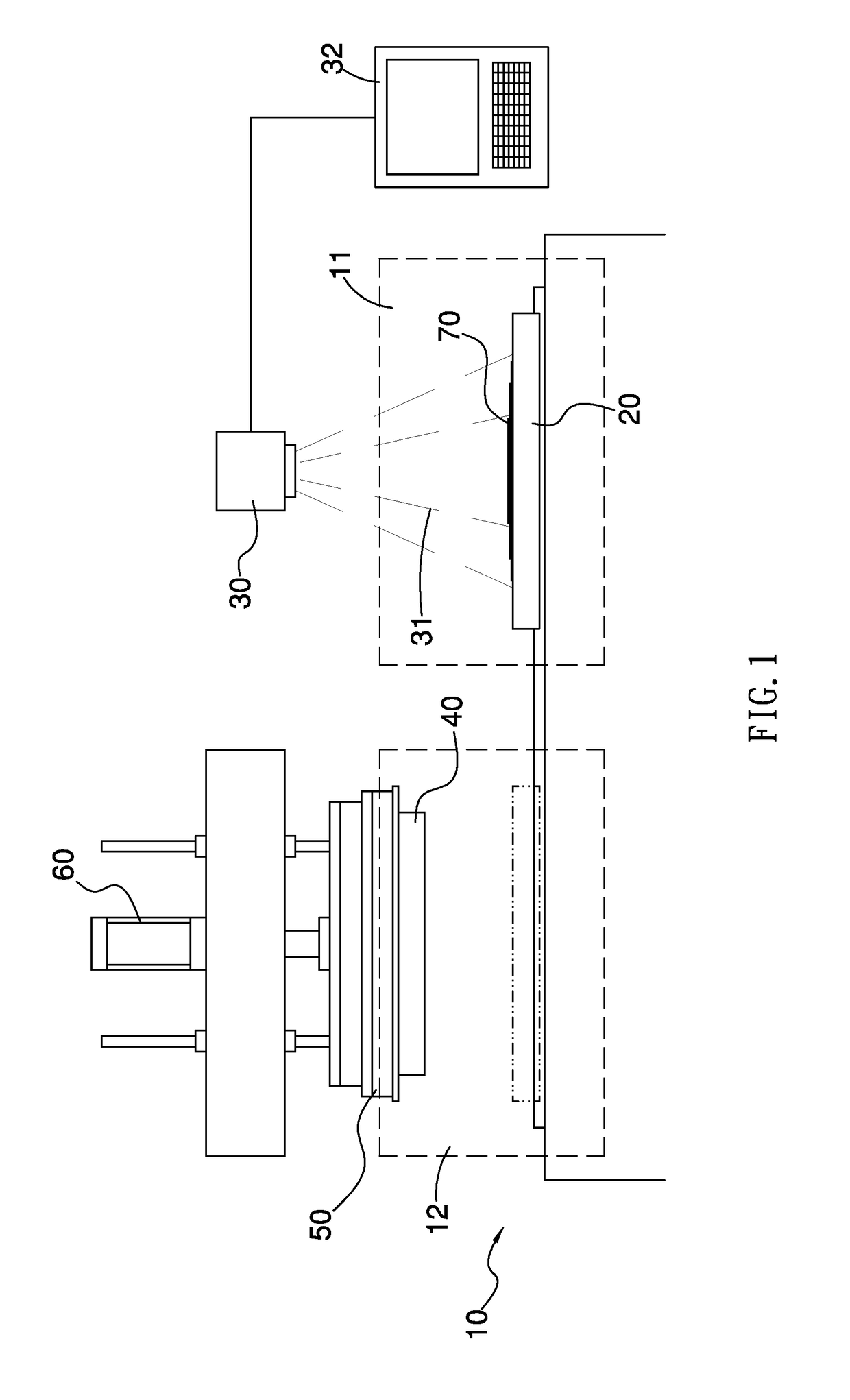

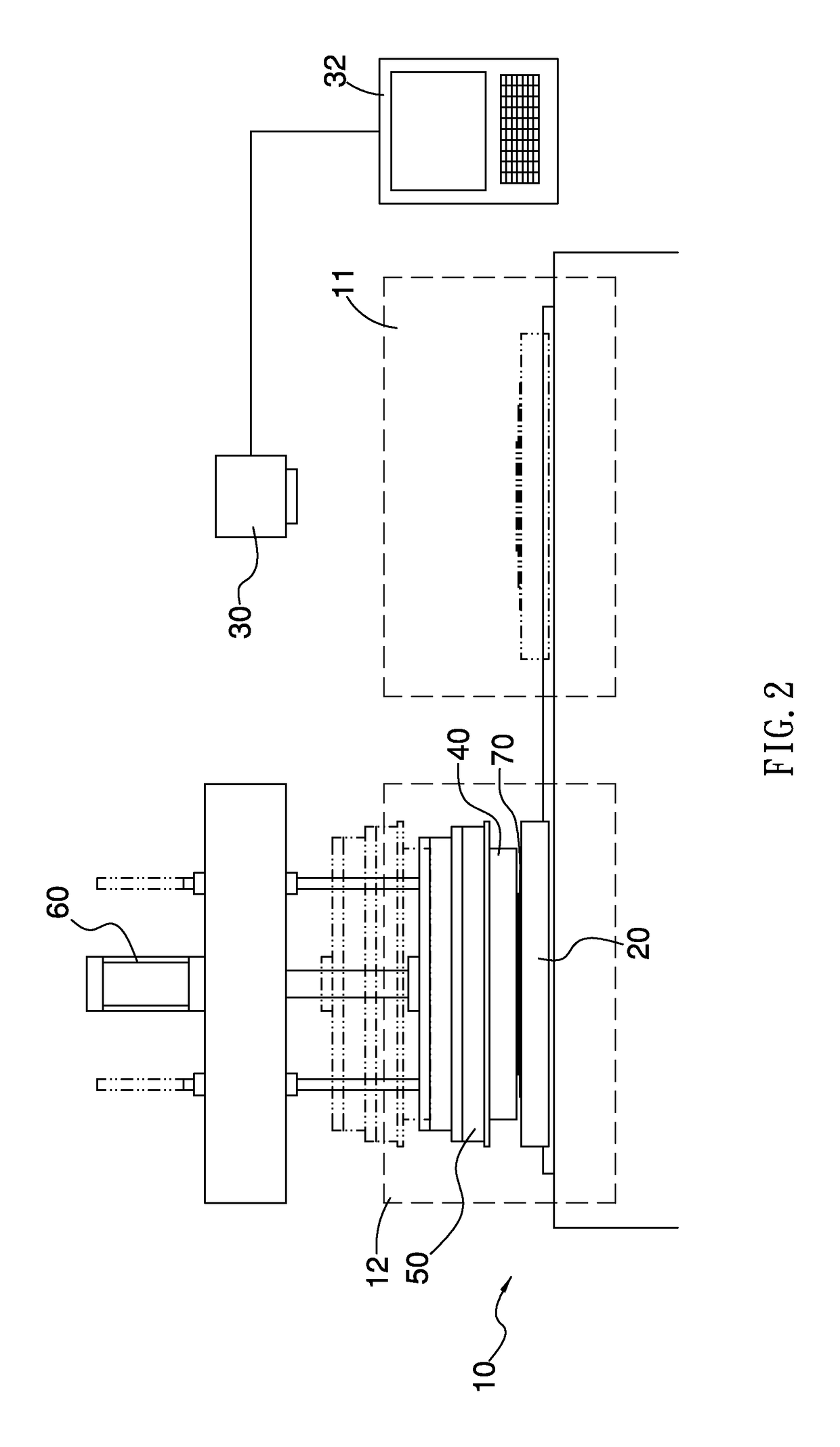

Compression Molding Apparatus

InactiveUS20170072603A1Quickly and accuratelyThe process is fast and accurateMaterials scienceProjector

A compression molding apparatus contains: a base, a carrying platform, at least one projector, a pressing mold, and a heater. The base includes a material feeding zone and a molding zone. The carrying platform moves into the molding zone from the material feeding zone, and when it is located in the material feeding zone, plural connecting pieces are stacked on the carrying platform. The at least one projector is fixed above the material feeding zone to project plural positioning images on the carrying platform, wherein each connecting piece is stacked on the carrying platform by aligning with each positioning image. The pressing mold is arranged above the molding zone, and when the carrying platform moves into the molding zone, the pressing mold moves to press the each connecting piece on the carrying platform. The heater is mounted on the base to heat the each connecting piece on the carrying platform.

Owner:CHAEI HSIN ENTERPRISE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com