Measuring device and method for axial load of column-shaped explosion container

A technology of axial load and explosion container, which is applied in the field of explosion mechanics, can solve the problems of unseen axial load research, etc., and achieve the effect of low experimental cost, strong practicability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

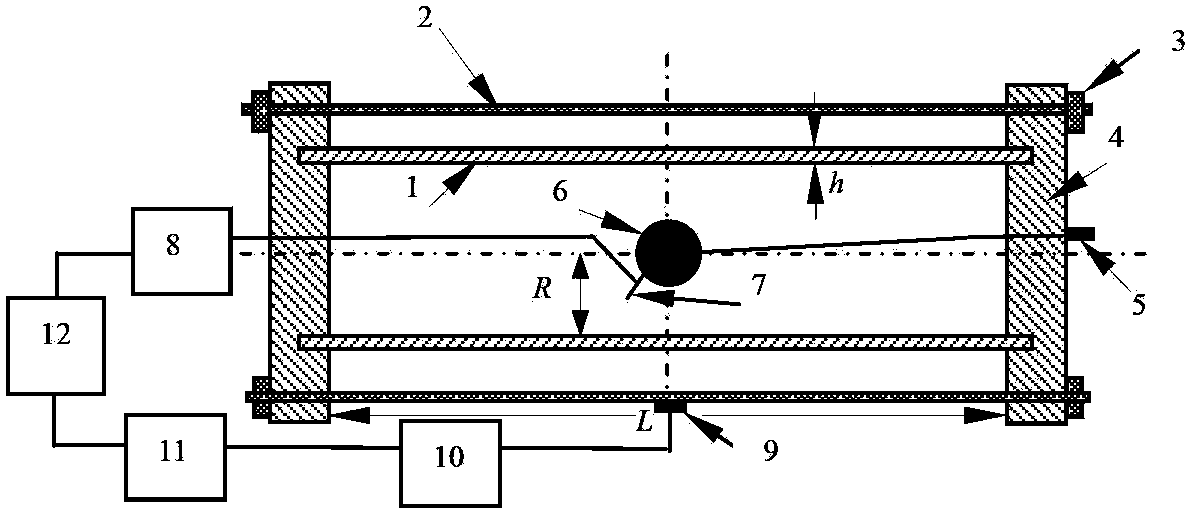

[0046] The measuring device for axial load of cylindrical explosive container under internal explosion is as follows:

[0047] An explosive 6 is placed in the center of the cylindrical shell 1 with wall thickness h, inner radius R and length L, and an electric probe 7 is pasted on the surface of the explosive 6. The two ends of the column shell 1 are installed in the plate head 4 with ring grooves. The two plate heads 4 are connected by the evenly distributed screw 2 and the nut 3. The screw 2 and the nut 3 are used to connect the plate head 4 and the column shell 1 The connection is fixed, and the strain gauge is pasted on the screw 2. The explosive 6 is detonated by the detonator 5, and the electric probe 7 on the surface of the explosive 6 can obtain the accurate time pulse waveform of the explosive 6 detonated on the oscilloscope 12 through the detonation velocity meter 8, so that the accurate time sequence of the explosive load acting in the cylinder 1 can be judged. The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com