Yarn storage device and yarn winding device

A yarn and storage technology, applied in spinning machine, open-end spinning machine, transportation and packaging, etc., can solve problems such as increased manufacturing cost and yarn damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

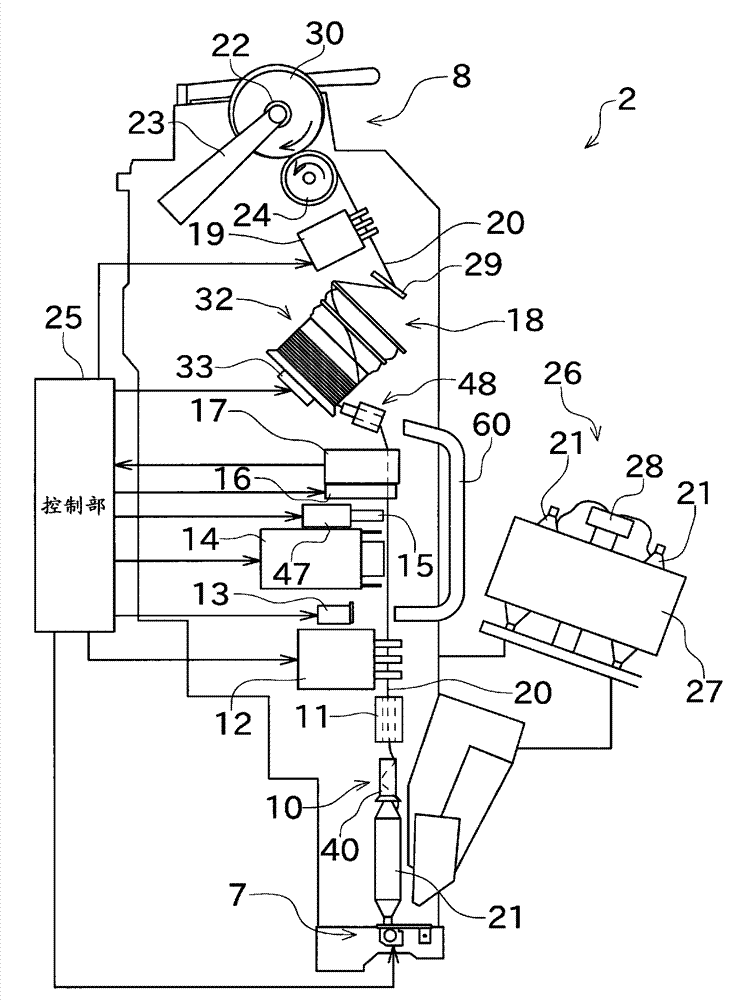

[0055] Next, embodiments of the present invention will be described. figure 1 It is a schematic side view of the winding unit 2 included in the automatic winder as the yarn winding machine according to the first embodiment of the present invention. The automatic winder of the present embodiment has a configuration in which a plurality of winder units 2 are arranged in parallel. In addition, this automatic winder includes a machine management device (not shown) for centrally managing the above-mentioned winding unit 2, and a blower box (not shown) including a compressed air source and a negative pressure source.

[0056] like figure 1 As shown, the winding unit 2 mainly includes a yarn feeding part 7 and a winding part 8 . The winding unit 2 is configured to unwind the yarn (spinning yarn) 20 supported by the yarn supplying bobbin 21 of the yarn supplying section 7 and rewind it to the package 30 . also, figure 1 The appearance of the winder unit 2 during normal winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com