A tensioning device for a frameless microcoil winding machine

A tensioner, skeletonless technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problem of the large size of the tensioner, the insufficiently compact installation layout, and the large size of mechanical tensioners or electronic tensioners. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

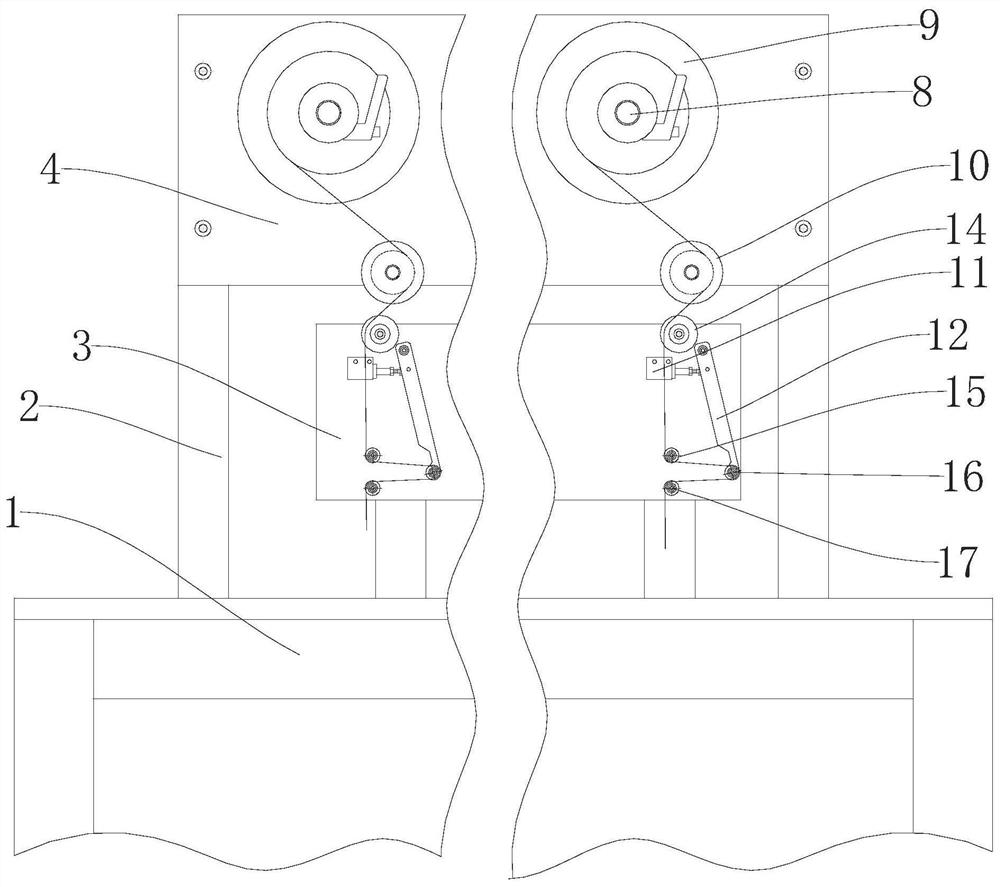

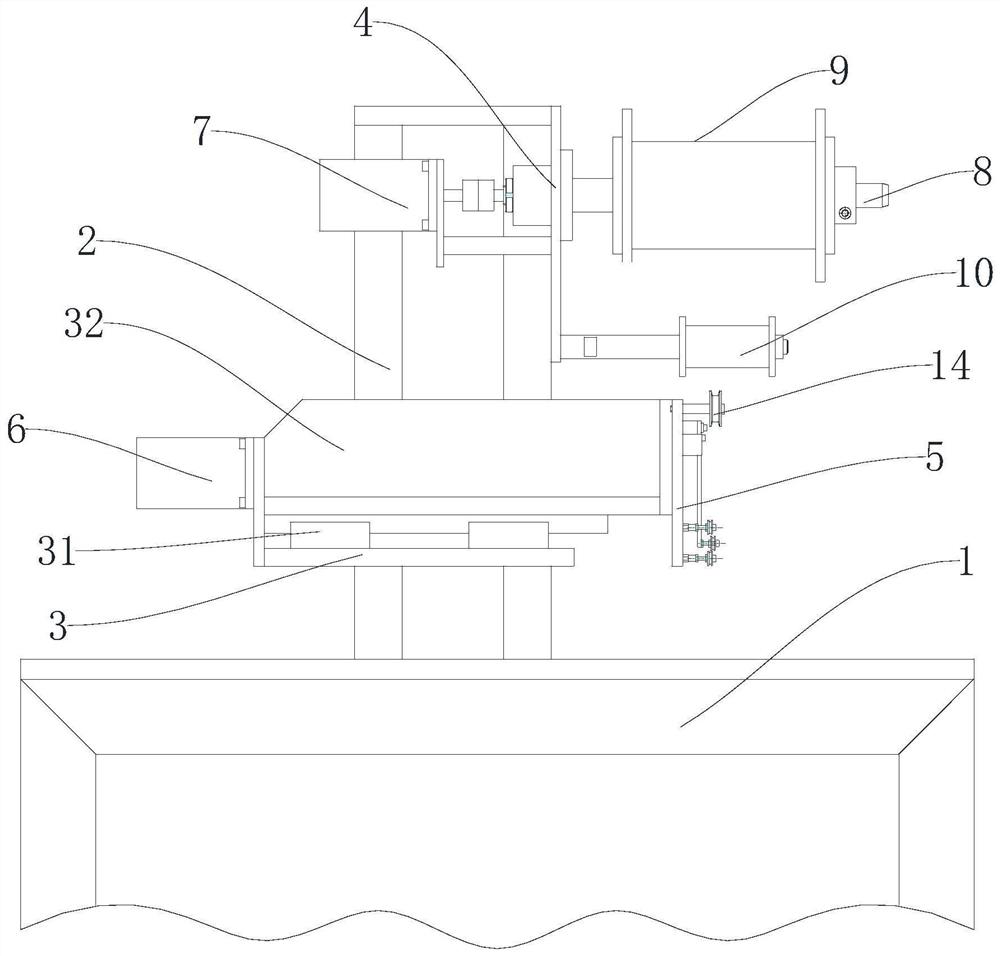

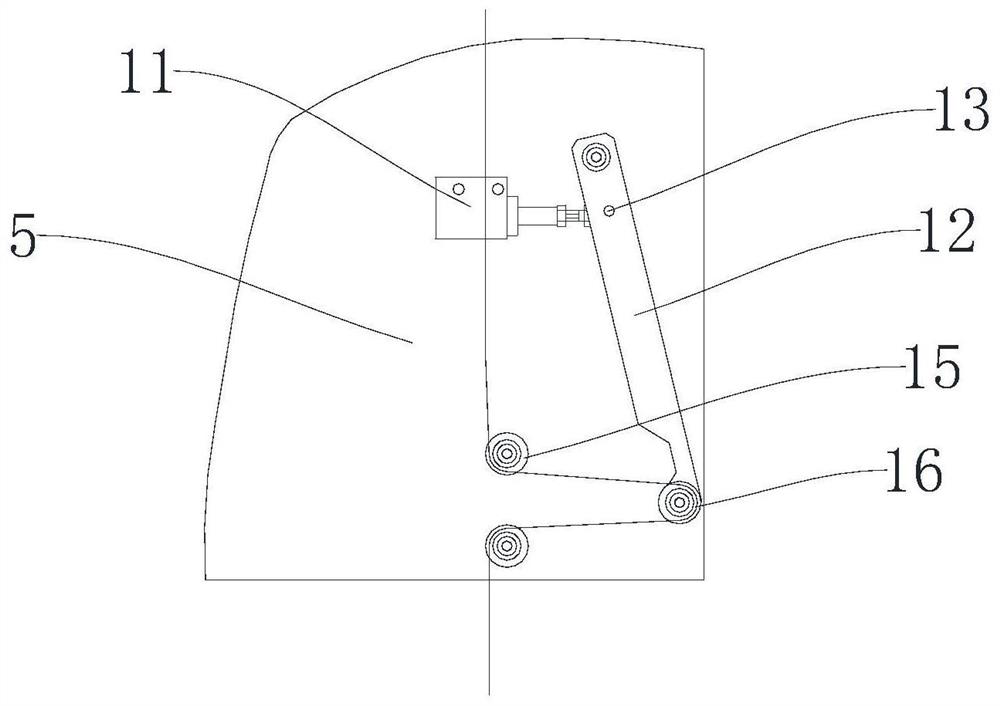

[0014]Embodiment: As shown in the figure, a tensioning device for a frameless microcoil winding machine includes a frame 1, a bracket 2 fixed on the frame 1, an installation platform 3, a first flat plate 4, and a second flat plate 5 , the wire inlet mechanism and the wire outlet mechanism, the installation platform 3 is fixedly arranged on the support 2, the installation platform 3 is provided with a guide rail 31 and the first motor 6, the guide rail 31 is provided with a moving block 32, and the moving block 32 is connected with the first motor 6 , the first motor 6 is used to drive the moving block 32 to move linearly along the guide rail 31, the first flat plate 4 is vertically arranged and fixedly arranged on the support 2, the second flat plate 5 is vertically arranged and fixedly arranged on the moving block 32, and the second flat plate 5 is vertically arranged and fixedly arranged on the moving block 32. The second flat plate 5 is located below the first flat plate 4;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com