Floating roll device for photogravure press

A technology of gravure printing machine and floating roller, which is applied to printing machines, rotary printing machines, printing, etc., and can solve the problems that the floating roller device cannot be placed arbitrarily, the space requirement of the floating roller device is high, and the tension control accuracy is affected. The effect of balanced adjustment, small tension fluctuation, and easy tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

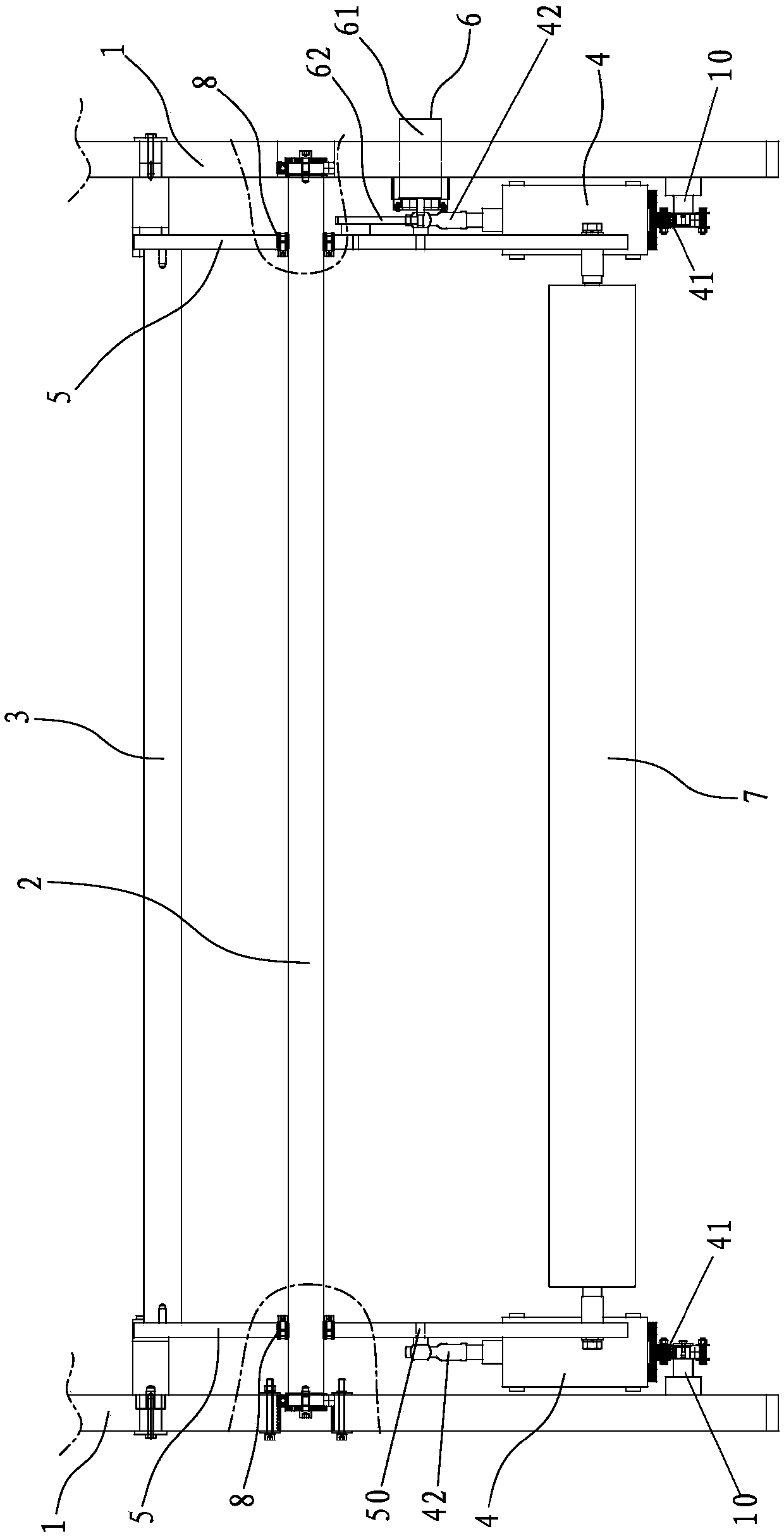

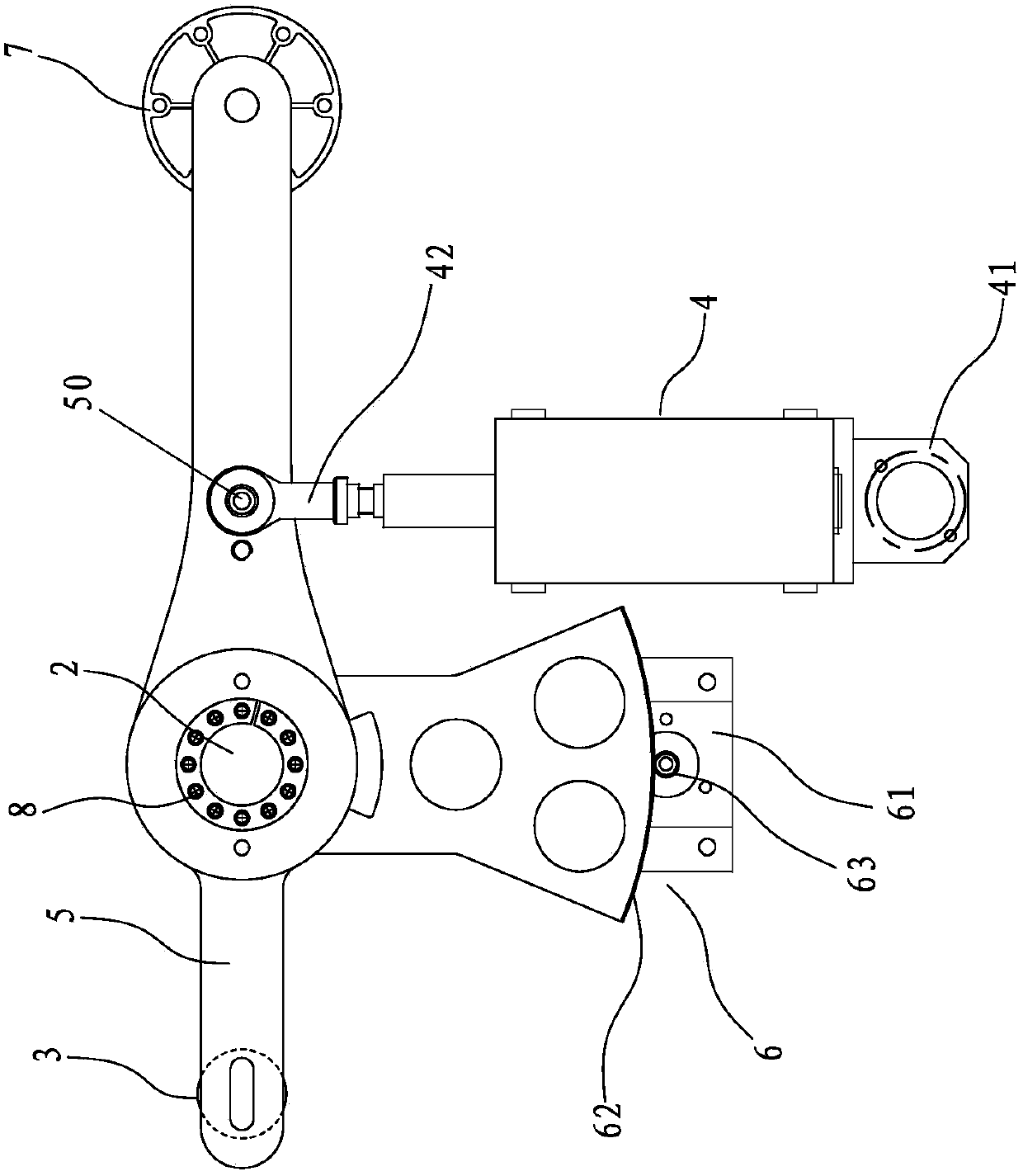

[0021] Such as Figure 1 to Figure 2 The floating roller device shown in the gravure printing machine is characterized in that it includes a rotating shaft 2 arranged on the frame 1, and two swing arms 5 that can follow the rotation of the rotating shaft 2 are respectively provided at both ends. On the swing arm 5 and on both sides of the rotating shaft 2 are respectively connected floating rollers 7 and counterweight rods 3, the floating rollers 7 and the counterweight rods 3 are parallel to the rotating shaft 2, and the swing arm 5 and the frame 1 is provided with a cylinder 4, the cylinder base of the cylinder 4 and the frame 1 are provided with a first rotating device connecting the two and allowing the two to rotate relative to each other, the piston rod of the cylinder 4 and the swing arm 5 There is a second rotating device connecting the two and allowing them to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com