Sheet-forming device

A forming equipment and paper sheet technology, applied in papermaking, paper machine, paper machine wet end, etc., can solve the problem of material density difference, achieve the effect of small free bundle length and improved bundle quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

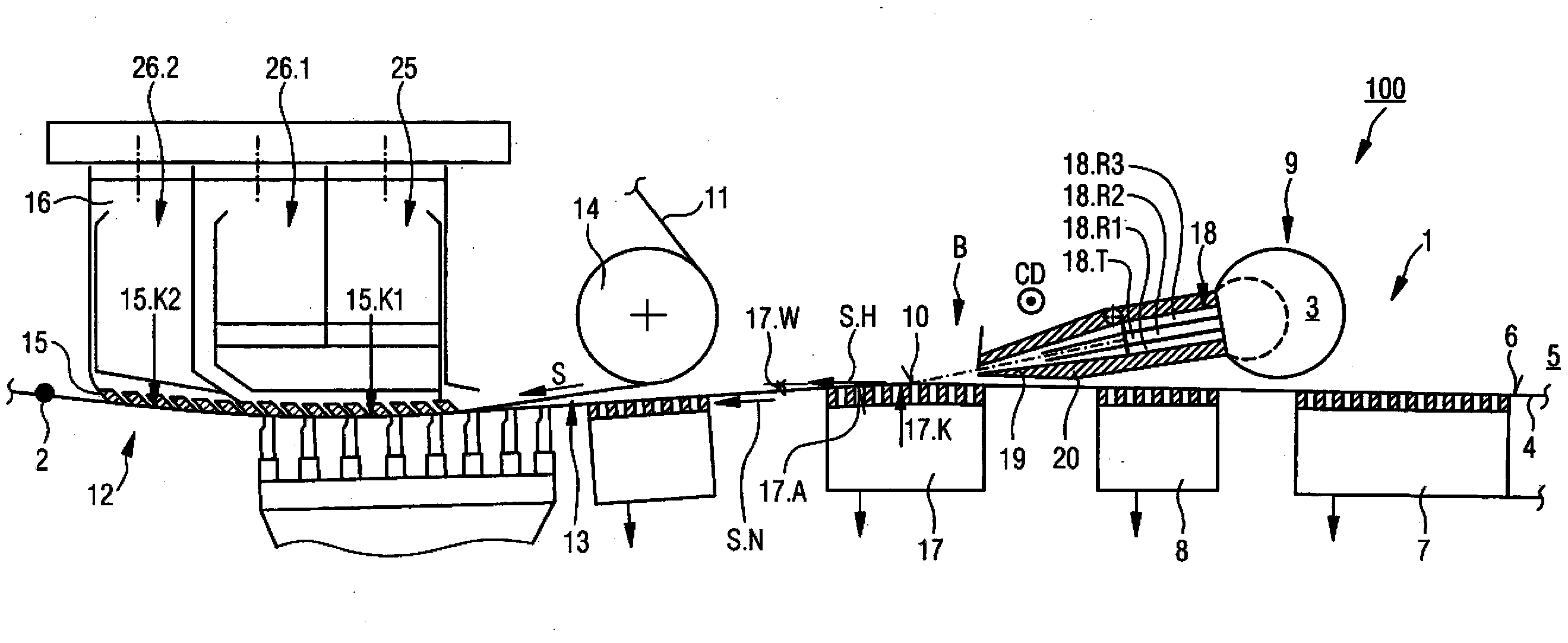

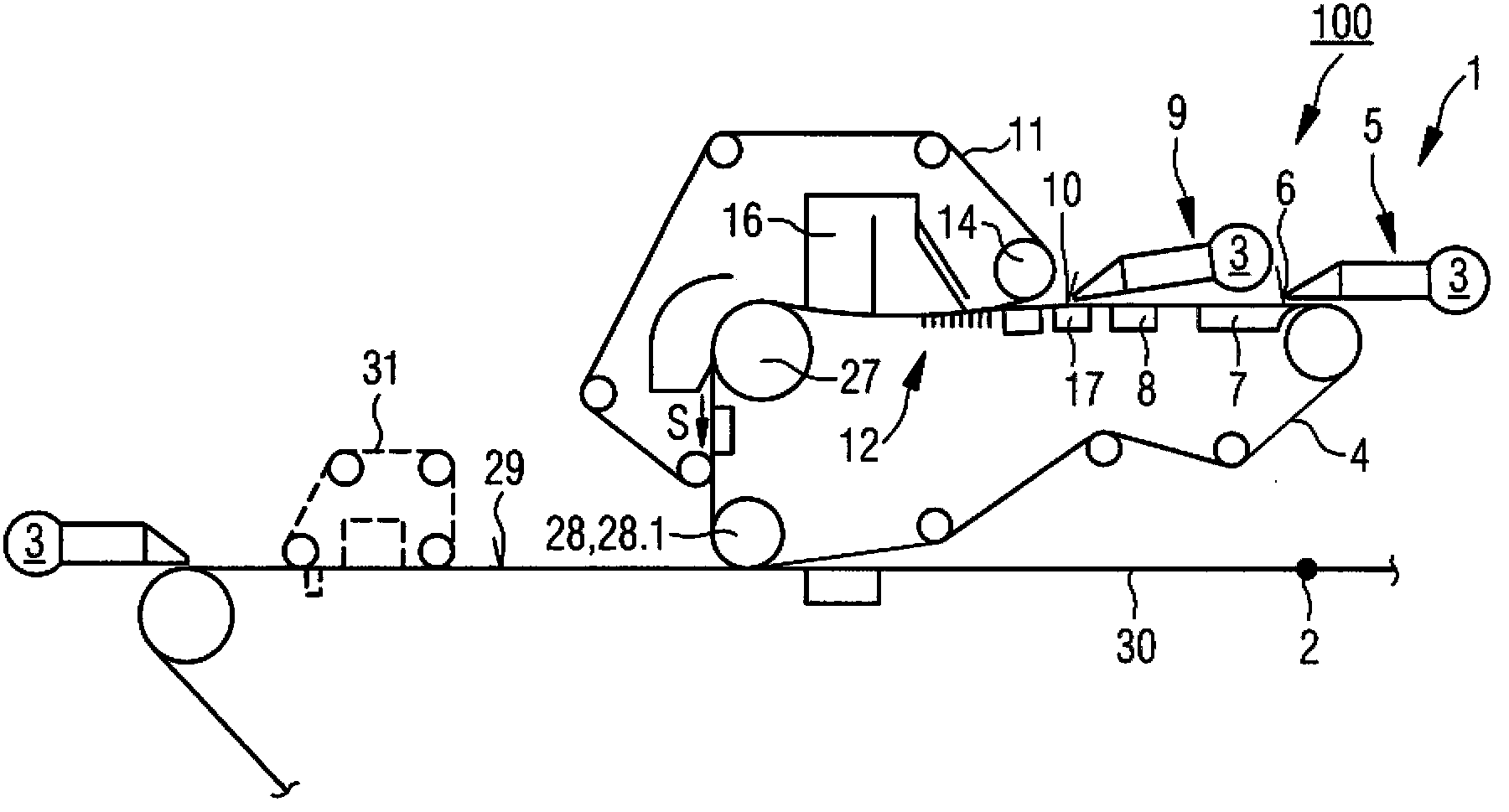

[0035] figure 1 Shows a schematic detail illustration of a preferred embodiment of a sheet forming plant 1 according to the invention for producing a two- or multi-layer fibrous web 2, in particular a cardboard or packaging web, from at least two fiber suspensions 3 .

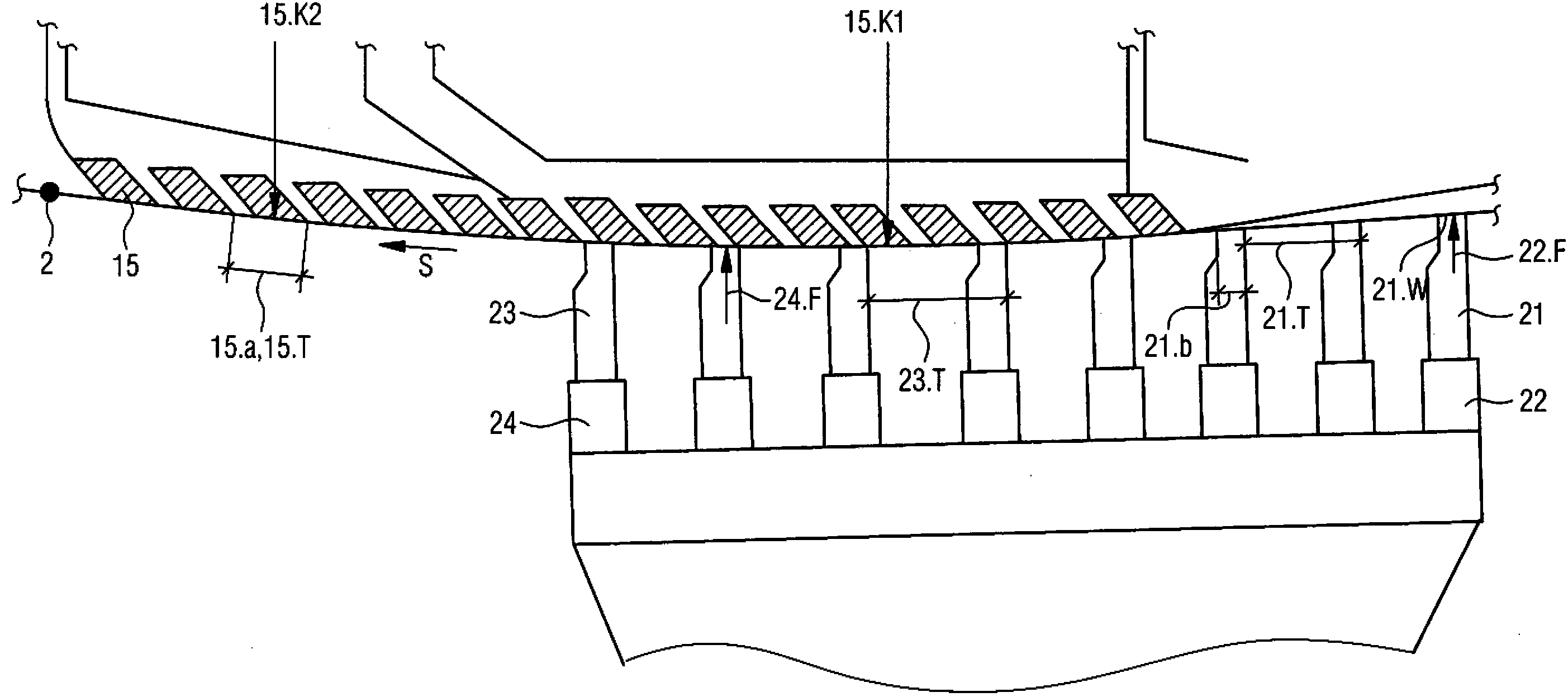

[0036] The illustrated sheet forming apparatus 1 comprises a first screen 4 preferably formed as a longitudinal screen, a first and preferably single-layer headbox 5 (see Figure 2 to Figure 4 ) applying a first layer 6 of fiber suspension 3 onto said first sieve 4 and said first sieve 4 together with the layer 6 of fiber suspension 3 lying thereon on a stationary sieve table 7 and a plurality of dewatering elements 8 upper guide (see also Figure 2 to Figure 4 ).

[0037] Furthermore, the illustrated sheet forming apparatus 1 comprises a second, preferably single-layer headbox 9 which applies a second layer 10 of the fiber suspension 3 to the The first layer 6 of the fiber suspension 3 is on. The two fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com