Pneumatic composite hole-type maize precision metering device

A seed metering device and combined hole technology, applied in sowing, planter parts, applications, etc., can solve the problems of poor adaptability, poor seed filling performance, and insufficient rotation speed of corn, achieve good adaptability, improve seed filling performance, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

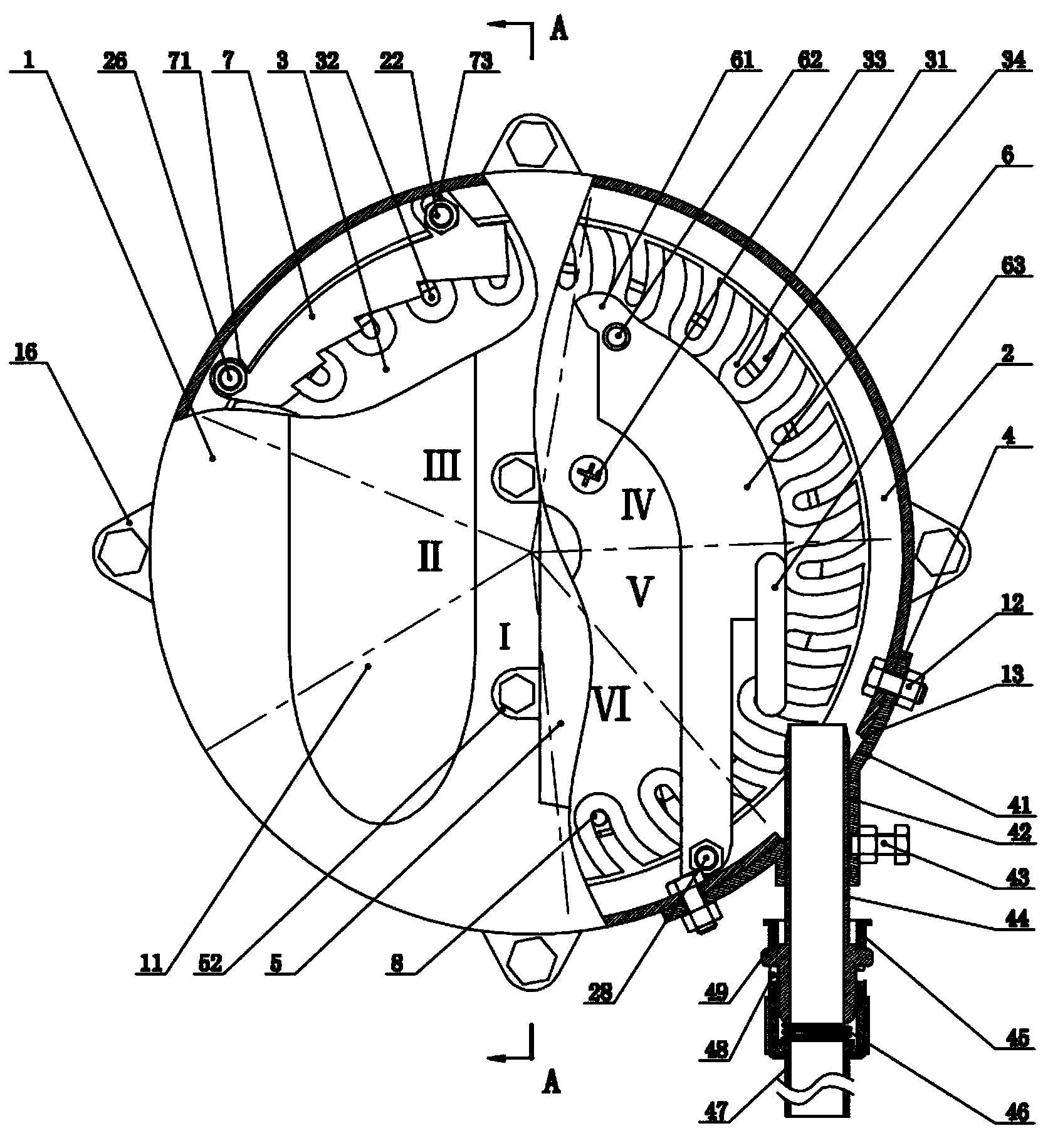

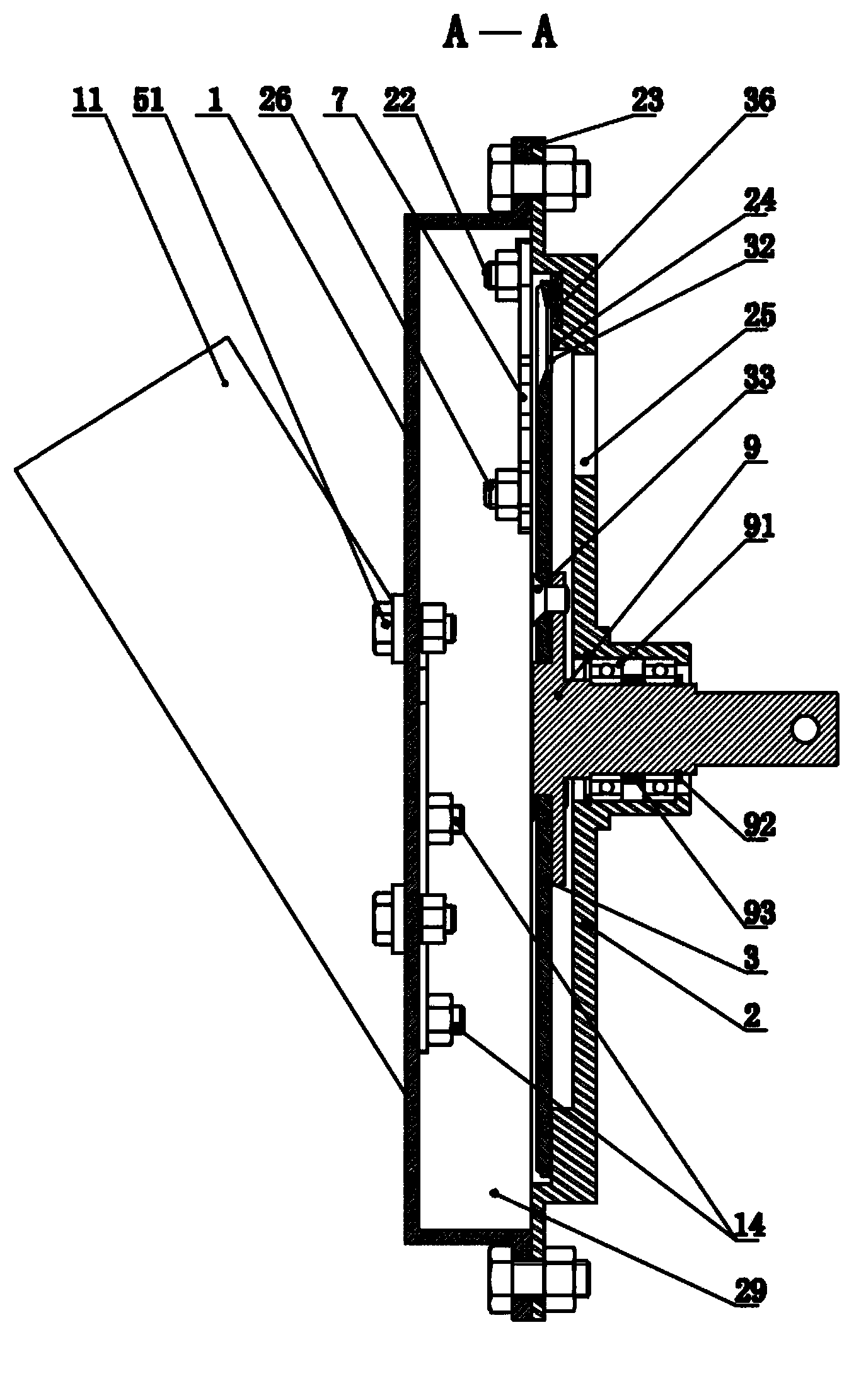

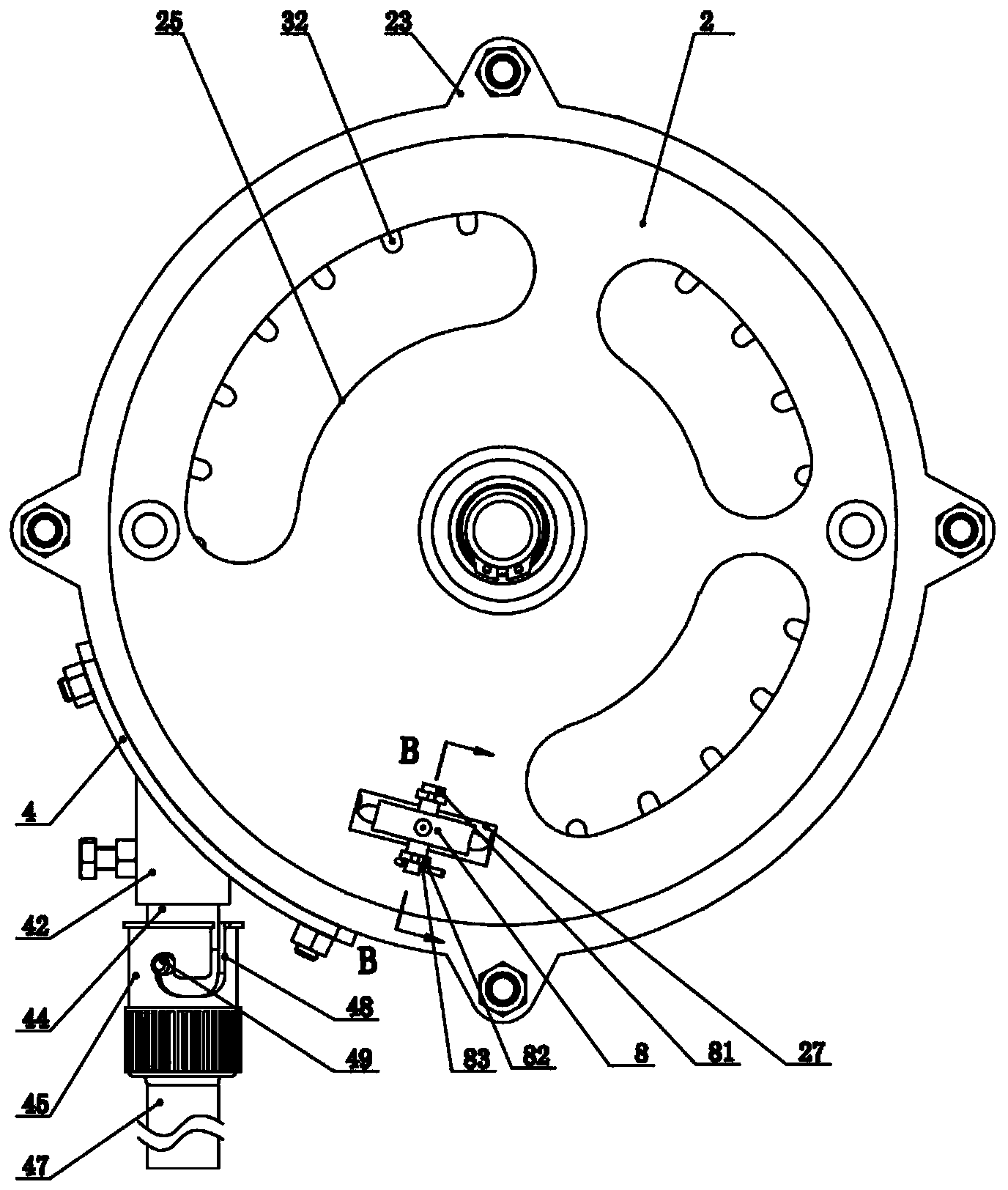

[0019] like Figure 1 ~ 6 Show, the invention includes the shell of the seedlings 1. The shell of the sarcal 2, the seeding disk 3. The type of the type of the type of the type of the gauge 4, the push -breeding board 6, the scraper board 7, the clearingSeed wheel 8 and seeding shaft 9.The housing 1 and the shell of the sarc device 2 are buckled together through a fixed card (16, 23) to form a circular cavity room 29, seed disk 3, pushing board 6, and scraping board 7 set up in theThis circular cavity room is within 29.Input device 4. The gas distribution room 5 and the clearance wheel 8 are installed in the circular chamber 29 outside

[0020] The housing 1 of the gaunting device 1 is a circular opening cavity. There is an inlet port 11 in the upper part, and a section of the curved gap 13 is opened in the lower part of the upper shell 1 of the seeder, which is used to install the transmission device 4.There are four bolts 17 and a semi -circular gap 19 on the side 1 of the shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com