Dreg-free beef tallow chafing dish bottom flavoring and preparation method

A hot pot bottom material and slag butter technology, which is applied in the food field, can solve the problems of muddy soup, abnormal flavor, affecting appetite, etc., and achieve the effects of avoiding rancidity, extremely low moisture content, and eliminating adhesion and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

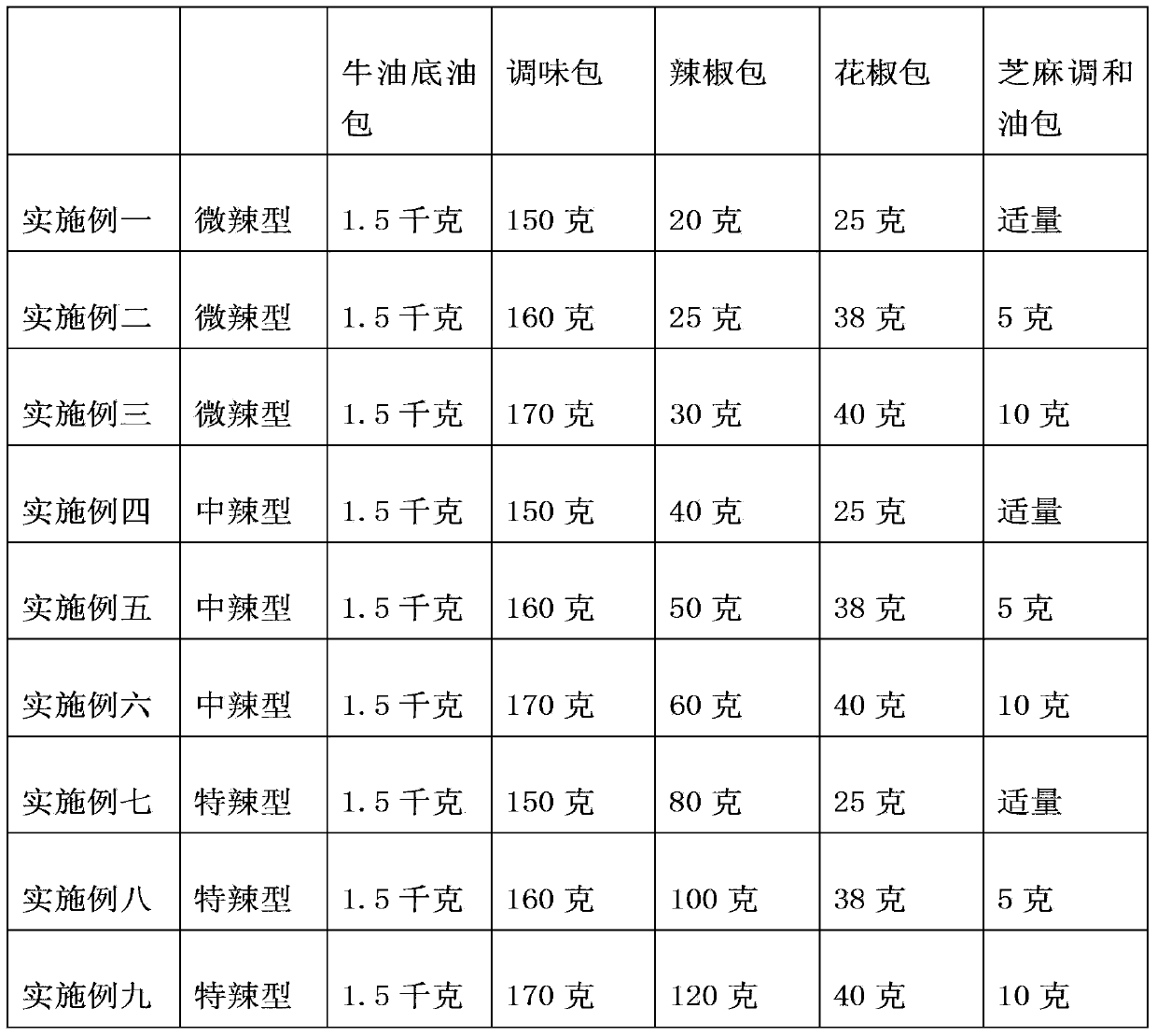

Examples

Embodiment Construction

[0009] The present invention will be further described in detail through specific implementation examples below.

[0010] An embodiment of the present invention provides a residue-free butter hot pot bottom material, comprising: a butter base oil bag;

[0011] The butter base oil package includes one or more of the following raw materials: by mass, 250-275 kg of butter, 35-76 kg of Henan bullet pepper, 4-12 kg of Chaotian pepper, and 5-8 kg of red pepper , green onions 5-9 kg, ginger 5.5-8.5 kg.

[0012] One embodiment of the present invention provides a method for preparing a residue-free butter hot pot bottom material, which includes: weighing various raw materials in the butter base oil package, butter, Henan bullet pepper, Chaotian striped pepper, red pepper, Green onions and ginger; melting the butter at 60-70°C; precooking Henan bullet peppers and Chaotiantiaozi peppers and crushing them to obtain cooked peppers with a water content of 60-70%; soaking red peppercorns to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com