Trolley sweeper

A cleaning machine and cleaning mechanism technology, applied in the direction of dust removal, cleaning methods and tools, cleaning methods using tools, etc., can solve the problems that affect the health of workers in the environment, the labor intensity of workers, and poor industrial and mining conditions, etc., to improve the quality of workers The effect of working environment, saving labor costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

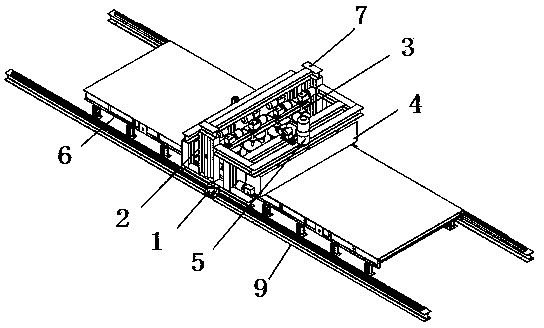

[0021] see figure 1 — Figure 5 , the trolley cleaning machine of the present invention is made up of walking system 1, push shovel mechanism 2, grinding and brushing mechanism 3, cleaning mechanism 4, dust removal system 5 and garbage collection box 6, and walking drive is installed on the frame 7 of walking system 1 The motor, the walking drive motor is connected to drive the traveling wheels, and the traveling wheels slide on the ground track 9; the frame 7 is equipped with a hydraulic lifting device, a brushing mechanism 3, a cleaning mechanism 4 and a dust removal system 5, and the garbage collection box 6 is installed on the frame Below the 7, the hydraulic elevating device is connected and installed with the push blade mechanism 2.

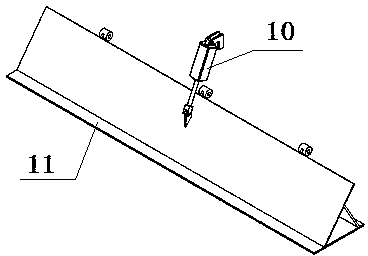

[0022] The above-mentioned push-shovel mechanism 2 is that the lower end of the hydraulic lift cylinder 10 is connected with a fixed triangular push-shovel 11 .

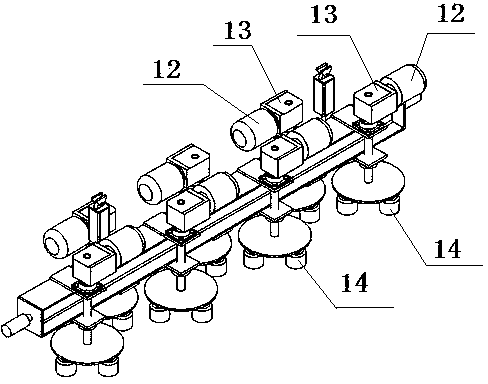

[0023] The above-mentioned brushing mechanism 3 is a plurality of motors 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com