Diamond pen microscale feed mechanism for bearing grinder interpolation and finishing

A bearing grinding machine and micro-feeding technology, which is applied to the parts of grinding machine tools, grinding drive devices, metal processing equipment, etc., can solve the problem of inability to eliminate the fit gap of the screw rod, the mechanical stroke is not easy to control, and there is no pre-tightening force, etc. Problems, to achieve the effect of easy and convenient design and processing, simple structure, and easy parts production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

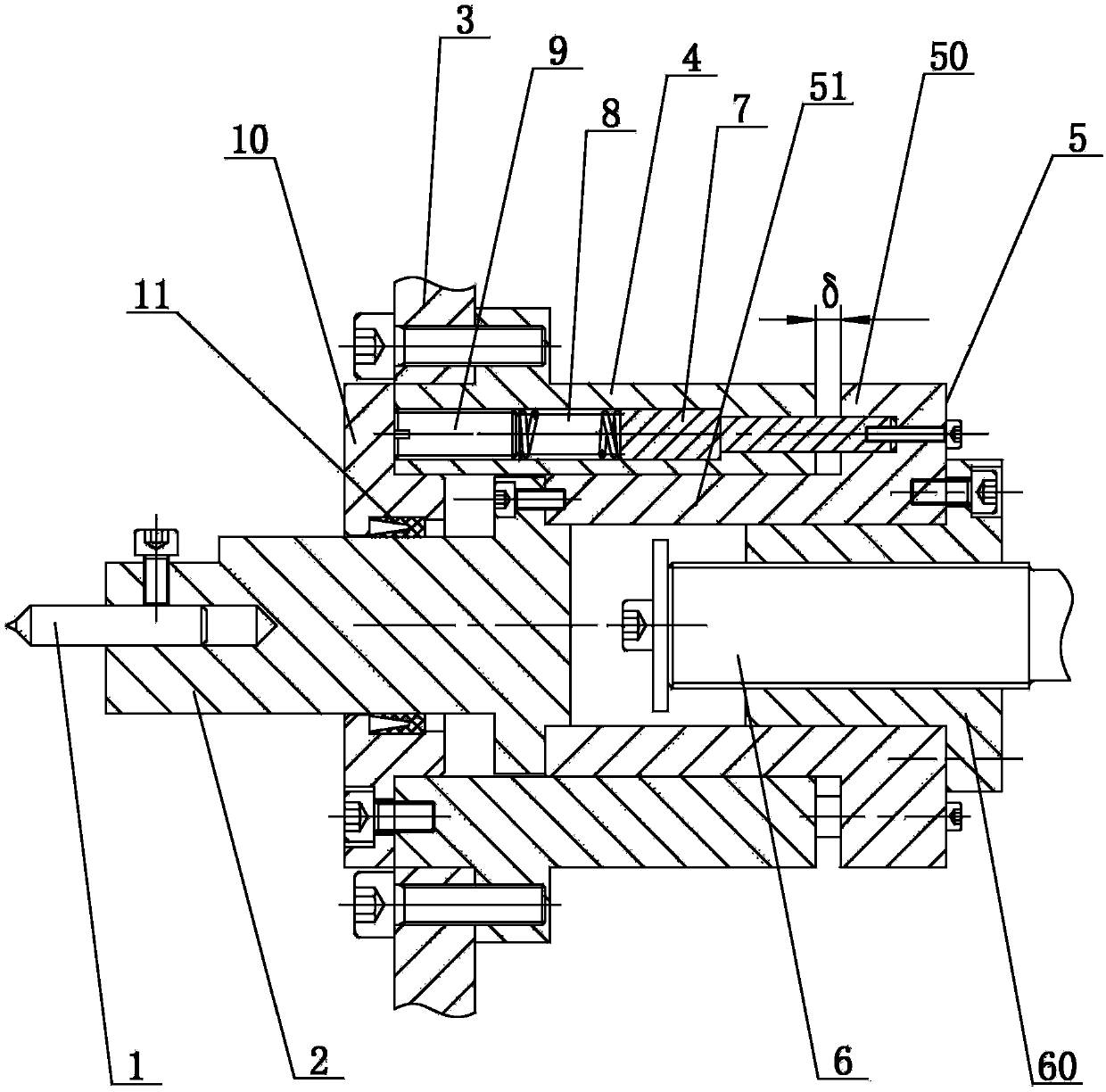

[0018] see figure 1 as shown, figure 1 It is a structural schematic diagram of a micro-feeding mechanism of a diamond pen used for interpolation and repairing of a bearing grinder provided in Embodiment 1 of the present invention.

[0019] In this embodiment, a diamond pen micro-feed mechanism for interpolation and repairing of bearing grinders includes a diamond pen 1, a diamond pen holder 2, a fixing seat 3, a large gland 4, a connecting sleeve 5 and a ball screw 6, the The diamond pen 1 is fixed on one end of the diamond pen holder 2, and the connecting sleeve 5 includes a connecting portion 50 and a cylindrical lead portion 51, and the connecting portion 50 is connected to the nut seat 60 of the ball screw 6 by connecting a fixing bolt, so that The end of the guide part 51 is connected to the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap