Maximum available power generation torque calculating method and system of hybrid electric vehicle motor

A technology for generating torque and maximum power, applied in the field of calculating the maximum available generating torque of hybrid electric vehicle motors, which can solve problems affecting the safety, durability and economy of hybrid electric vehicles, reduce energy loss and pollutant emissions, and improve economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

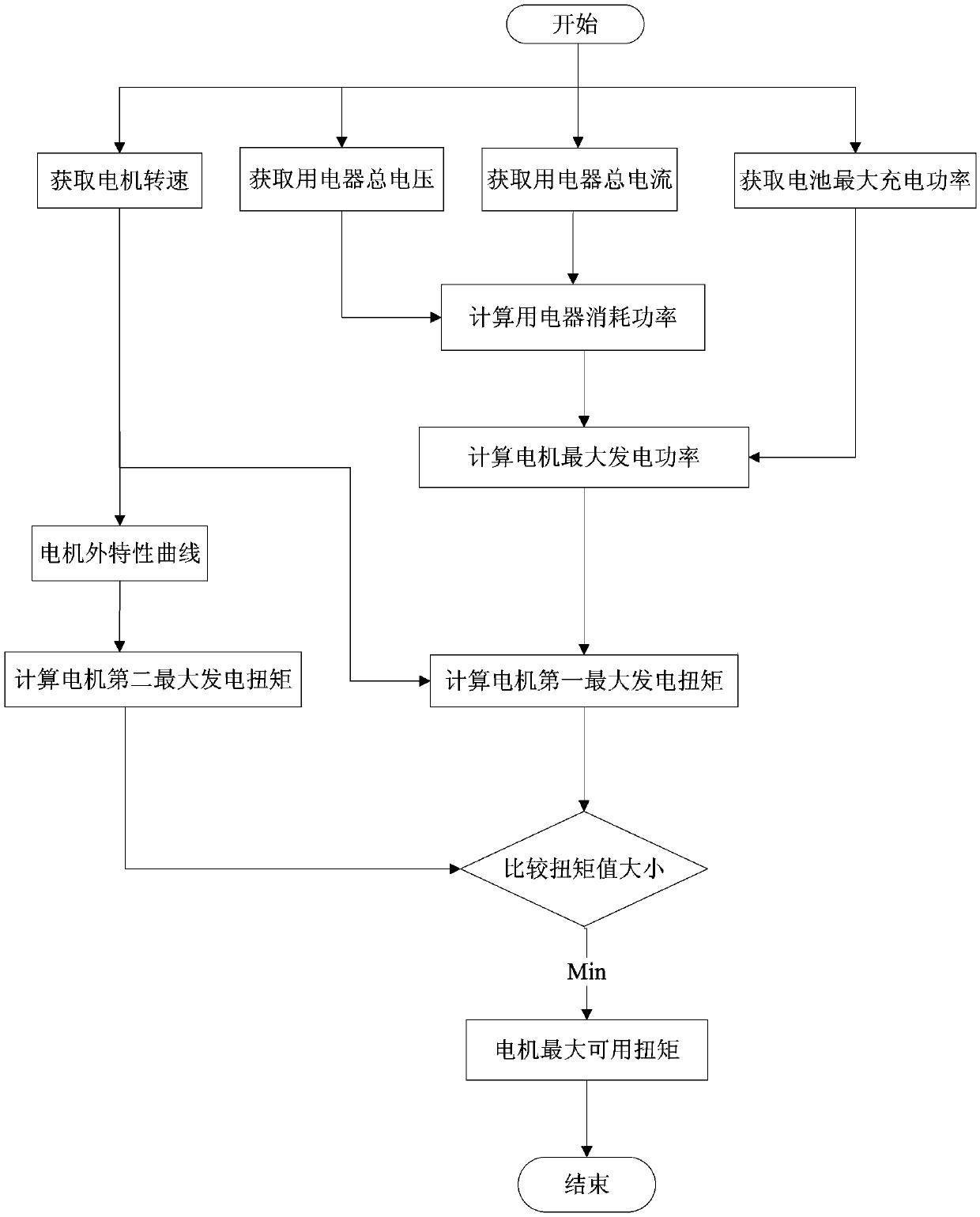

[0021] Such as figure 1 As shown, a calculation method for the maximum available power generation torque of a hybrid electric vehicle motor, including:

[0022] Obtain the total voltage and total current of the high-voltage end of the high-voltage converter, and calculate the current consumption power of the low-voltage electrical appliance through the obtained total voltage and current; obtain the maximum charging power of the power battery, and subtract the current consumption of the low-voltage electrical appliance from the maximum charging power of the power battery. The power consumption of the motor is used to obtain the maximum allowable power generation of the motor; to obtain the motor speed, the allowable maximum power generation of the motor is divided by the current speed of the motor to obtain the first maximum power generation torque of the motor.

[0023] The second maximum power generation torque of the motor is calculated by looking up the motor speed and the ...

Embodiment 2

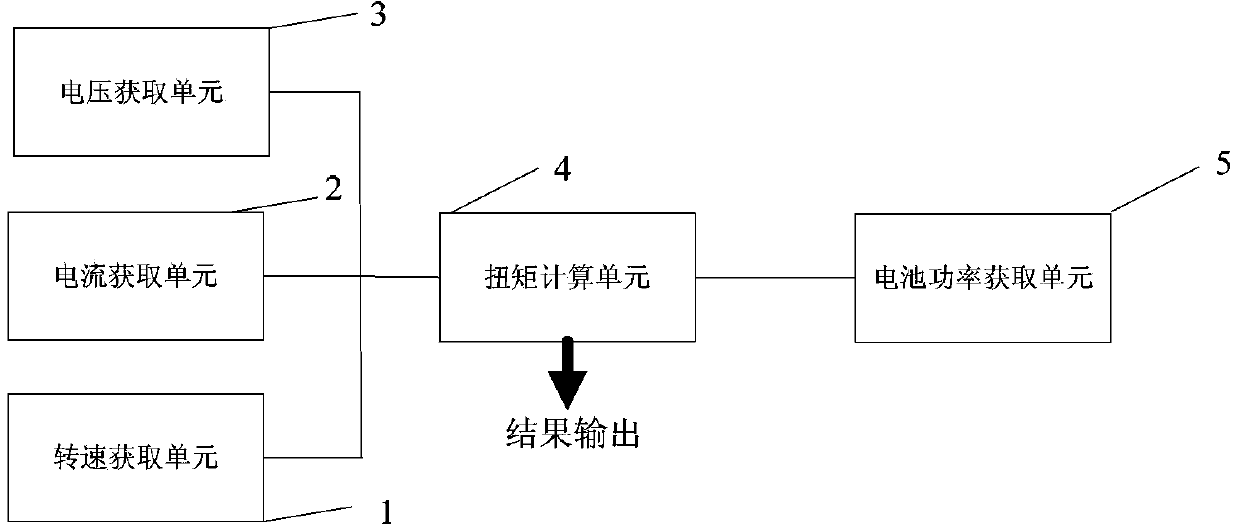

[0026] On the basis of Embodiment 1, this application also provides a calculation and control system for the maximum available generating torque of the motor, such as figure 2 As shown, the system includes a rotational speed acquisition unit 1 , a current acquisition unit 2 , a voltage acquisition unit 3 , a torque calculation unit 4 , and a battery power acquisition unit 5 . The battery power acquisition unit 5 is connected to the torque calculation unit 4 for the interaction of the maximum charging power signal of the power battery; the voltage acquisition unit 3 is connected to the torque calculation unit 4 to provide the total voltage of the high-voltage end of the high-voltage converter; the current acquisition unit 2 and The torque calculation unit 4 is connected to provide the total current at the high-voltage end of the high-low voltage converter; the speed acquisition unit 1 is connected to the torque calculation unit 4 to provide the motor speed.

[0027] The batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com