Bamboo fiber textile product with high wet strength and preparation method thereof

A textile product and bamboo fiber technology, applied in the field of bamboo fiber textile products and its preparation, can solve the problems of bamboo fiber flowing, antibacterial, breathable discount, low bamboo fiber content, etc., and achieve good wrinkle resistance, high wet strength, and comfortable wearing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

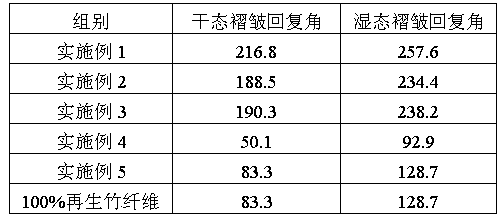

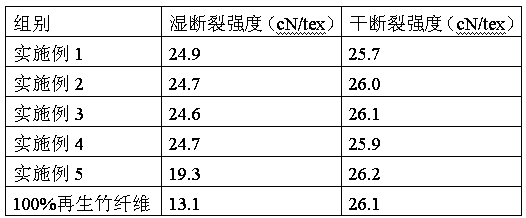

Examples

Embodiment 1

[0026] Embodiment 1: a kind of high bamboo fiber textile product of wet strength is obtained by the raw material blending of following weight ratio:

[0027] Regenerated Bamboo Fiber 88%

[0028] Apocynum fiber 5.9 %

[0029] Jute fiber 2.0 %

[0030] Polyester fiber 1.8 %

[0031] Pineapple Leaf Fiber 2.3 %

[0032] The preparation method of the present invention is as follows: blending regenerated bamboo fiber, apocynum fiber, jute fiber, polyester fiber and pineapple leaf fiber according to the ratio in the formula to obtain a blended product, and then after finishing, that is, the blended product is prepared in nano TiO 2 Immerse in the finishing agent for 50 minutes, then dry it, and then finish it with a compound enzyme. The dosage of the compound enzyme is 1.6% of the weight of the blended product, the pH is 4.4, and the bath ratio is 1:12. After 55 minutes of treatment, take out the blended product. For finished products, heat up to 80°C, keep warm for 10 minut...

Embodiment 2

[0037] Embodiment 2: a kind of bamboo fiber textile product with high wet strength, its preparation method is: carry out blending with regenerated bamboo fiber, apocynum fiber, jute fiber, polyester fiber and pineapple leaf fiber by the ratio in the formula, obtain blended product, Then carry out post-finishing, that is, blending products in nano-TiO 2 Immerse in the finishing agent for 45 minutes, then dry it, and then finish it with a compound enzyme. The dosage of the compound enzyme is 1.1% of the weight of the blended product, the pH is 4.1, and the bath ratio is 1:10. After 50 minutes of treatment, take out the blended product. For finished products, heat up to 80°C, keep warm for 10 minutes to inactivate the enzyme, rinse, neutralize, and cool to obtain the finished blended product;

[0038] The nano-TiO 2 The preparation method of the finishing agent is: sodium dodecylbenzenesulfonate, nano-TiO 2 Mixed with water, their mass ratio is sodium dodecylbenzenesulfonate: ...

Embodiment 3

[0041] Embodiment 3: a kind of bamboo fiber textile product with high wet strength, its preparation method is: carry out blending with regenerated bamboo fiber, apocynum fiber, jute fiber, polyester fiber and pineapple leaf fiber by the ratio in the formula, obtain blended product, Then carry out post-finishing, that is, blending products in nano-TiO 2 Immerse in the finishing agent for 60 minutes, then dry it, and then finish it with a compound enzyme. The dosage of the compound enzyme is 2.0% of the weight of the blended product, the pH is 4.7, and the bath ratio is 1:14. After 60 minutes of treatment, take out the blended product. For finished products, heat up to 80°C, keep warm for 10 minutes to inactivate the enzyme, rinse, neutralize, and cool to obtain the finished blended product;

[0042] The nano-TiO 2 The preparation method of the finishing agent is: sodium dodecylbenzenesulfonate, nano-TiO 2 Mixed with water, their mass ratio is sodium dodecylbenzenesulfonate: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com