Reciprocating piston pumps with flow-through plain bearings

A reciprocating, plunger pump technology, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve problems such as quantitative pump wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

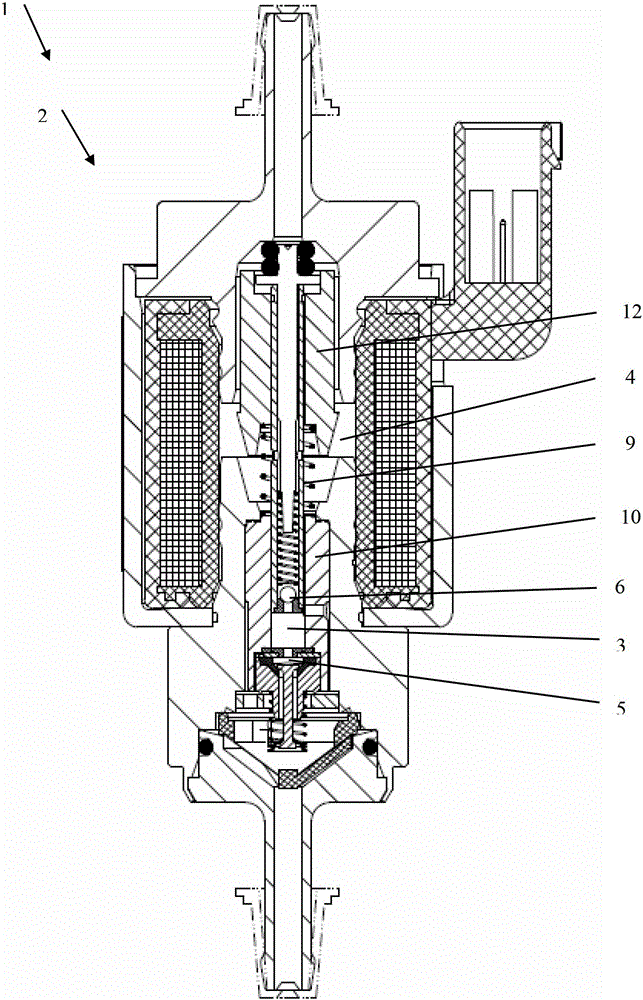

[0049] A reciprocating plunger pump 1 driven by an electromagnet 2 contains two check valves 5 and 6 and also contains a plunger 9 which is hermetically housed in a cylinder 10 and supports the armature post of the electromagnet 2 stuffed.

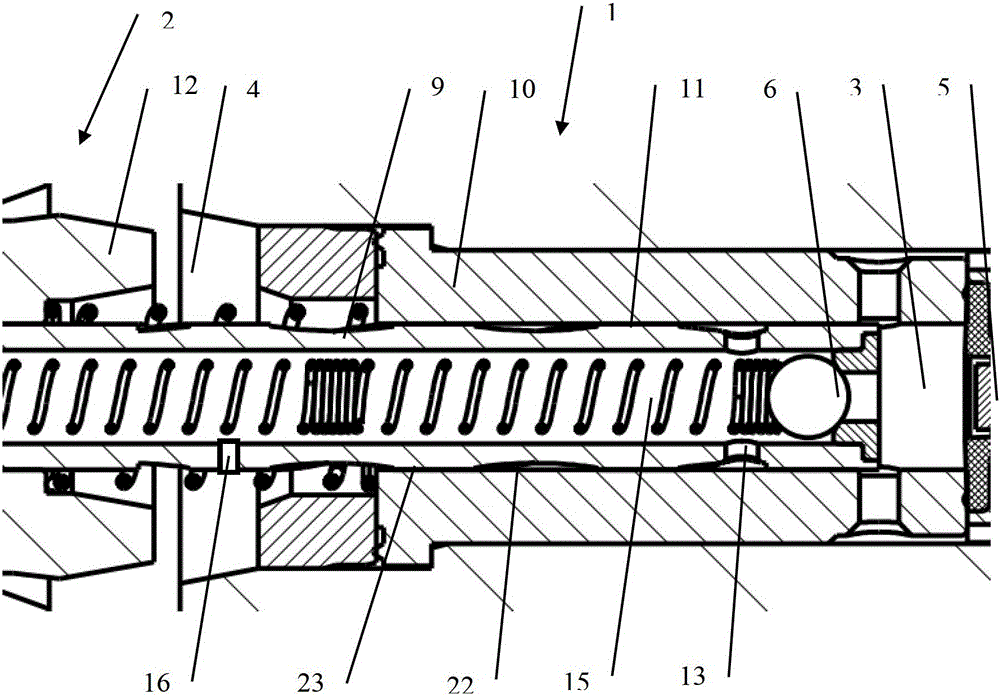

[0050] figure 2 It is shown that an elongated recess is provided in one of the two surfaces of the bearing gap 11 between the plunger 9 and the cylinder 10, through which recess the conveyed liquid flow flows. For this purpose, the transverse bore 13 creates a connection from the valve 6 to the bearing gap 11 .

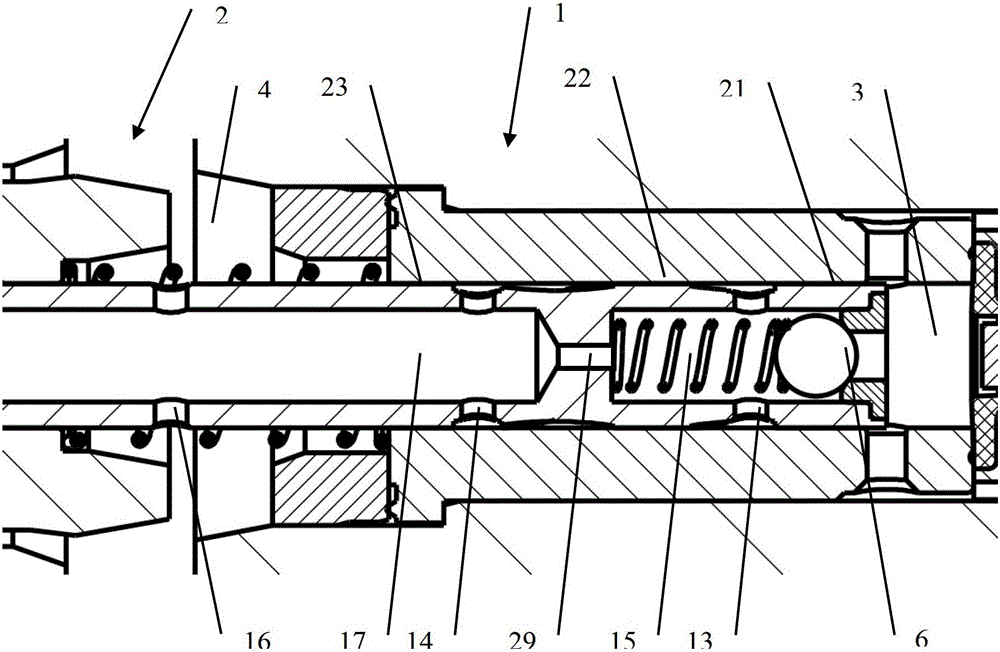

[0051] in accordance with figure 2 In the first and second embodiments of the reciprocating plunger pump 1 the liquid flow from the valve 6 is guided wholly or partly via the transverse hole 13 into a recess in the surface of the plunger 9 or in the surface of the cylinder 10 , and is guided into the armature chamber 4 via the bearing areas 22 and 23 , wherein the recess extends into the armature chamber 4 and does not extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com