Heat dispersion disk sheet clearance support system for disk type heat dispersion machine

A technology of heat dispersing machine and supporting system, applied in the direction of fluid pressure actuating device, etc., to achieve the effect of safe system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

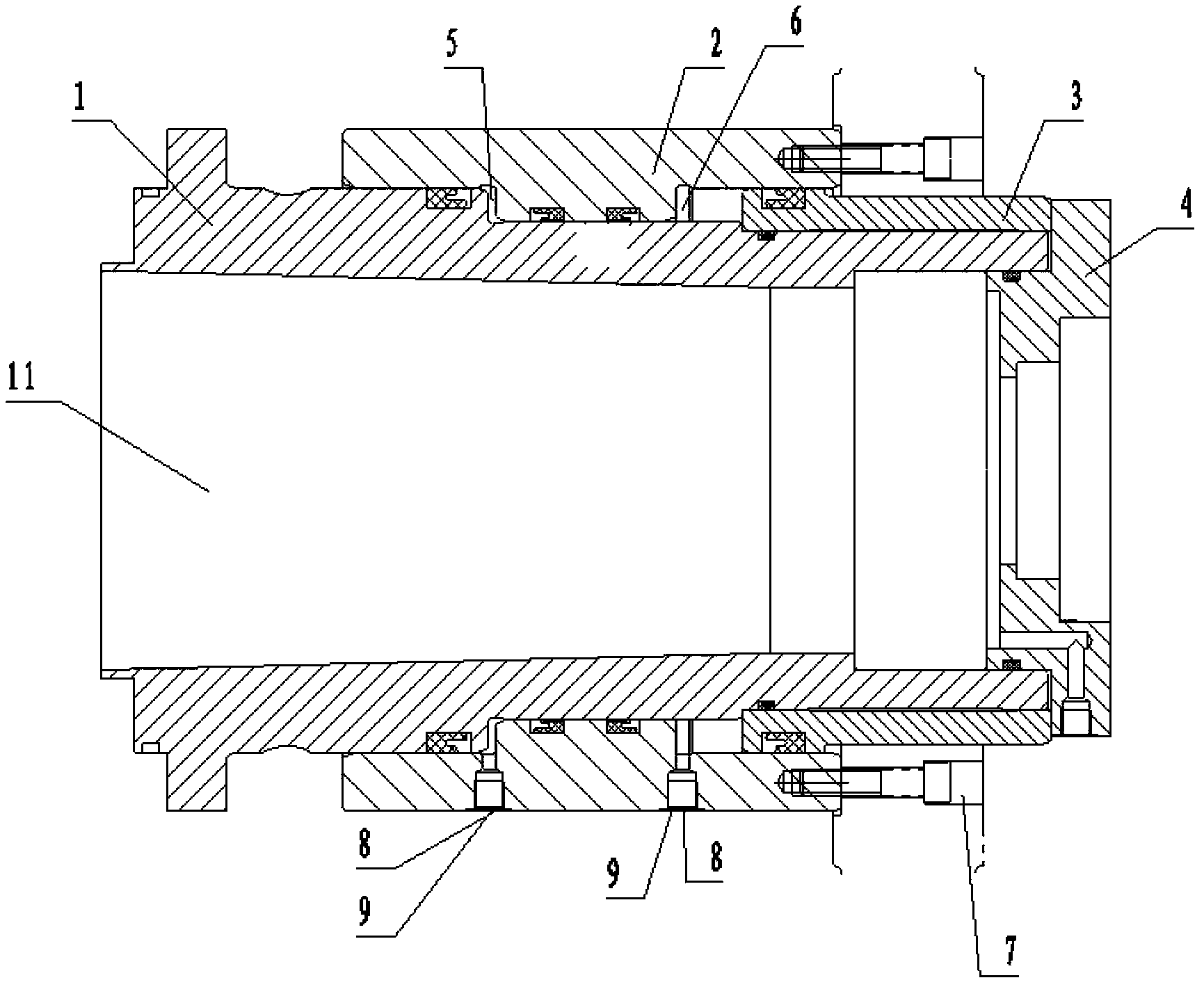

[0018] A heat dispersing disc gap support system of a disc heat dispersing machine includes a single hydraulic cylinder, and the single hydraulic cylinder includes a piston rod 1, a cylinder liner 2, a distance sleeve 3 and a fixed gland 4, The piston rod is a hollow piston rod, the transmission shaft can pass through the inner chamber of the piston rod, and the rear end of the piston rod inner chamber 11 is provided with a bearing mounting position, and the described cylinder liner is an inner convex cylinder liner, and the inner The convex cylinder liner divides the cylinder liner into two working chambers 5 and 6 with the same inner diameter. Working, the length of the inner concave part of the piston rod is longer than the length of the inner convex part of the cylinder liner, and a distance sleeve for positioning the stroke of the piston rod is set between the piston rod and the rear part of the cylinder liner. The diameter is equal to the inner diameter of the rear part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com