Plastic steering oil tank assembly

A technology of assembly and oil tank, which is applied in the field of plastic steering oil tank assembly, can solve the problems of unfavorable production line vacuum filling, cab cannot be turned over, and oil filling process is inconvenient, so as to improve the convenience of filling, The effect of superior performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

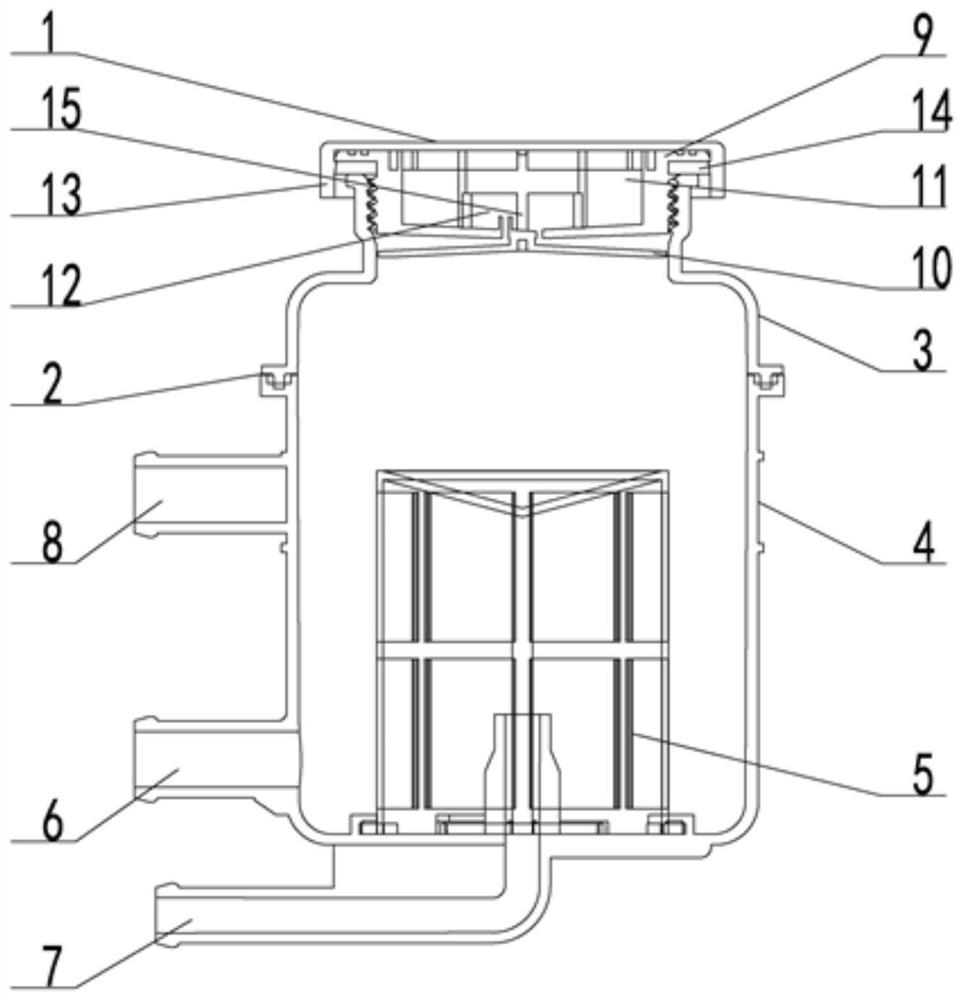

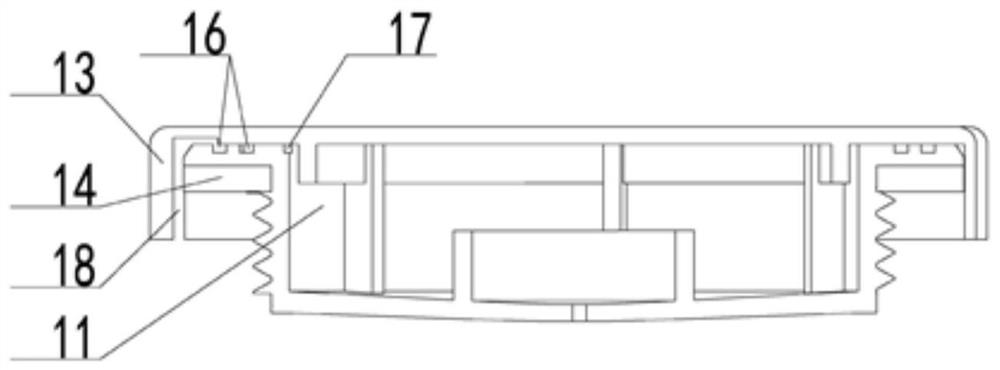

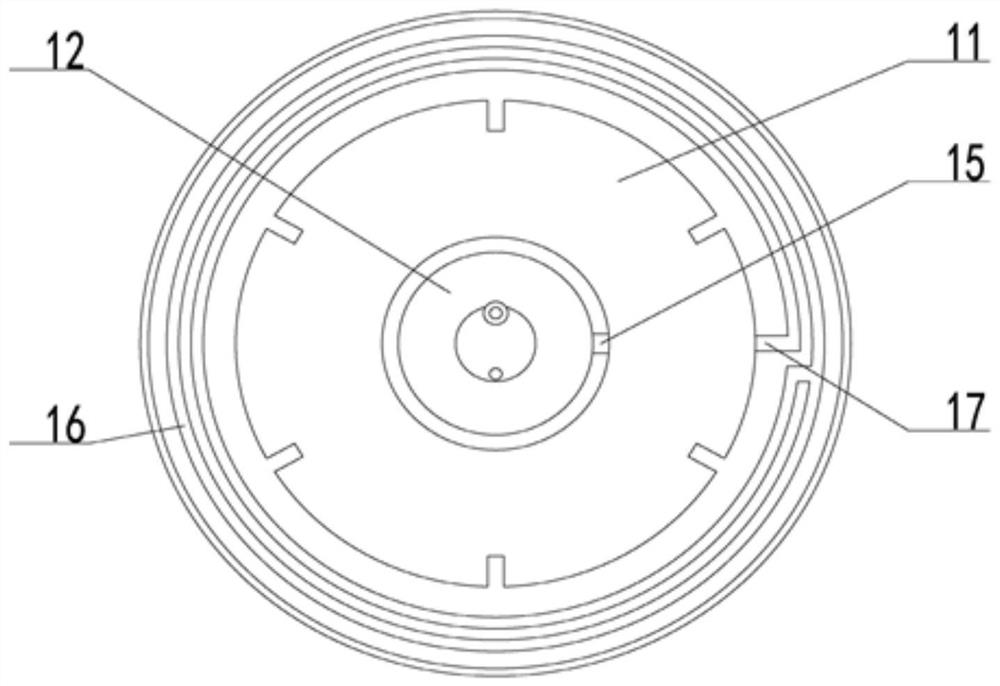

[0016] Such as Figure 1-Figure 3 As shown, the present invention provides a plastic steering oil tank assembly, comprising a tank cover assembly 1, a tank body 2 and a filter screen 5, the tank cover assembly 1 is composed of a tank cover 13, an oil-gas separation chamber 9 and a gasket 14, the oil-gas separation chamber 9 has a two-stage oil-gas separation structure, the first-stage separation chamber 11 and the second-stage separation chamber 12, the bottom of the first-stage oil-gas separation chamber has a slope, and the lowest point is provided with an oil return hole to ensure that the oil in the chamber The liquid returns to the tank body: the tank body 2 is composed of an upper tank body 3 and a lower tank body 4, and the lower tank body 4 is reserved for a filling nozzle 8, an oil outlet nozzle 6 and an oil return nozzle 7 to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com