Three-position five-path valve

A technology for three-position five-way valves and spools, applied in multi-way valves, valve devices, engine components, etc., can solve problems such as damage to spools and valve sleeves, and achieve the effects of saving material costs and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

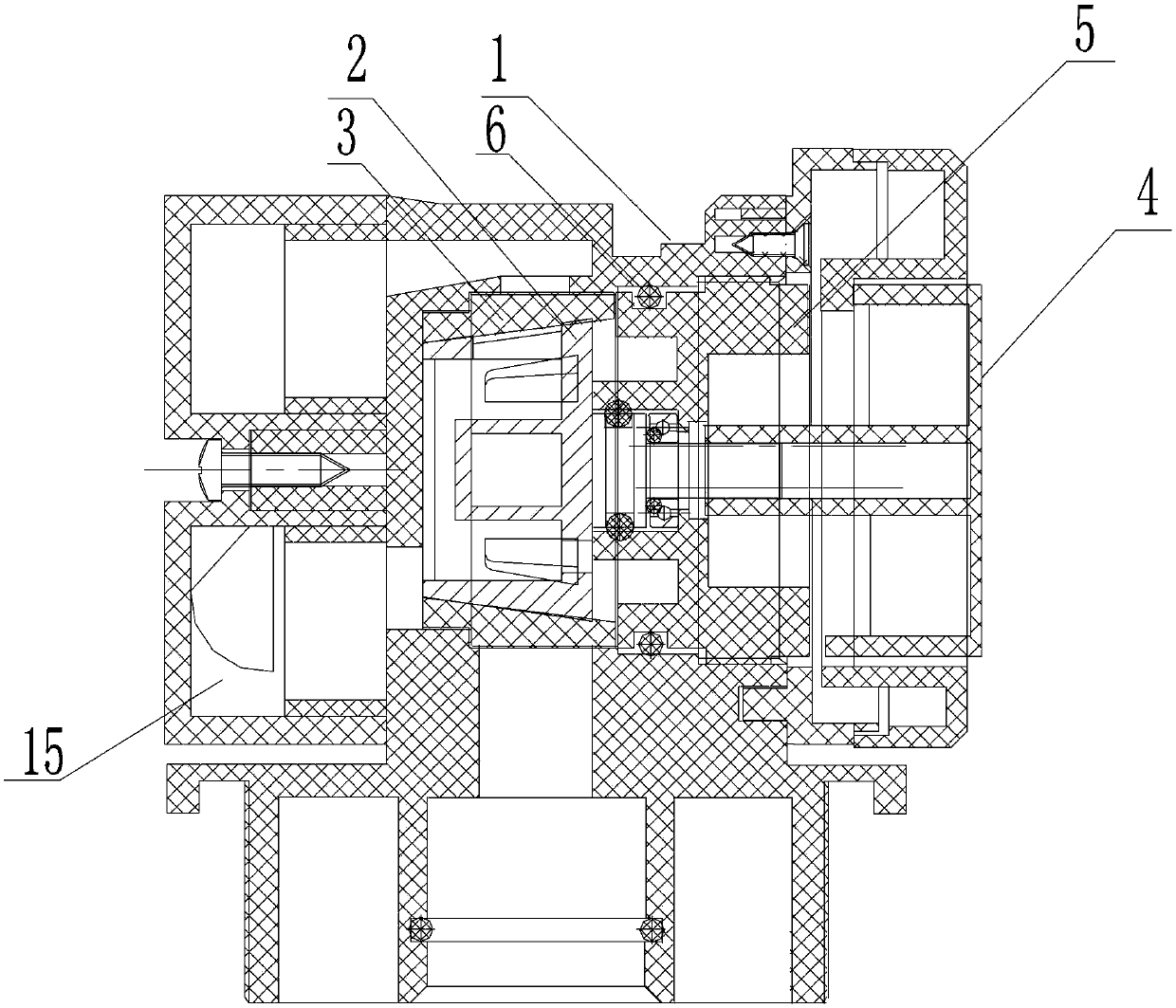

[0024] like figure 1 As shown, a three-position five-way valve includes a valve body 1, a cavity is provided in the valve body, a valve core 2 and a valve sleeve 3 are arranged in the cavity, and the valve core 2 and the valve sleeve 3 are slidingly fitted;

[0025] One end of the rotating shaft of the valve core 2 is fixedly connected with a knob 4, and a bonnet 5 is set on the rotating shaft of the spool, and the bonnet 5 is tightly connected with the cavity on the valve body 1;

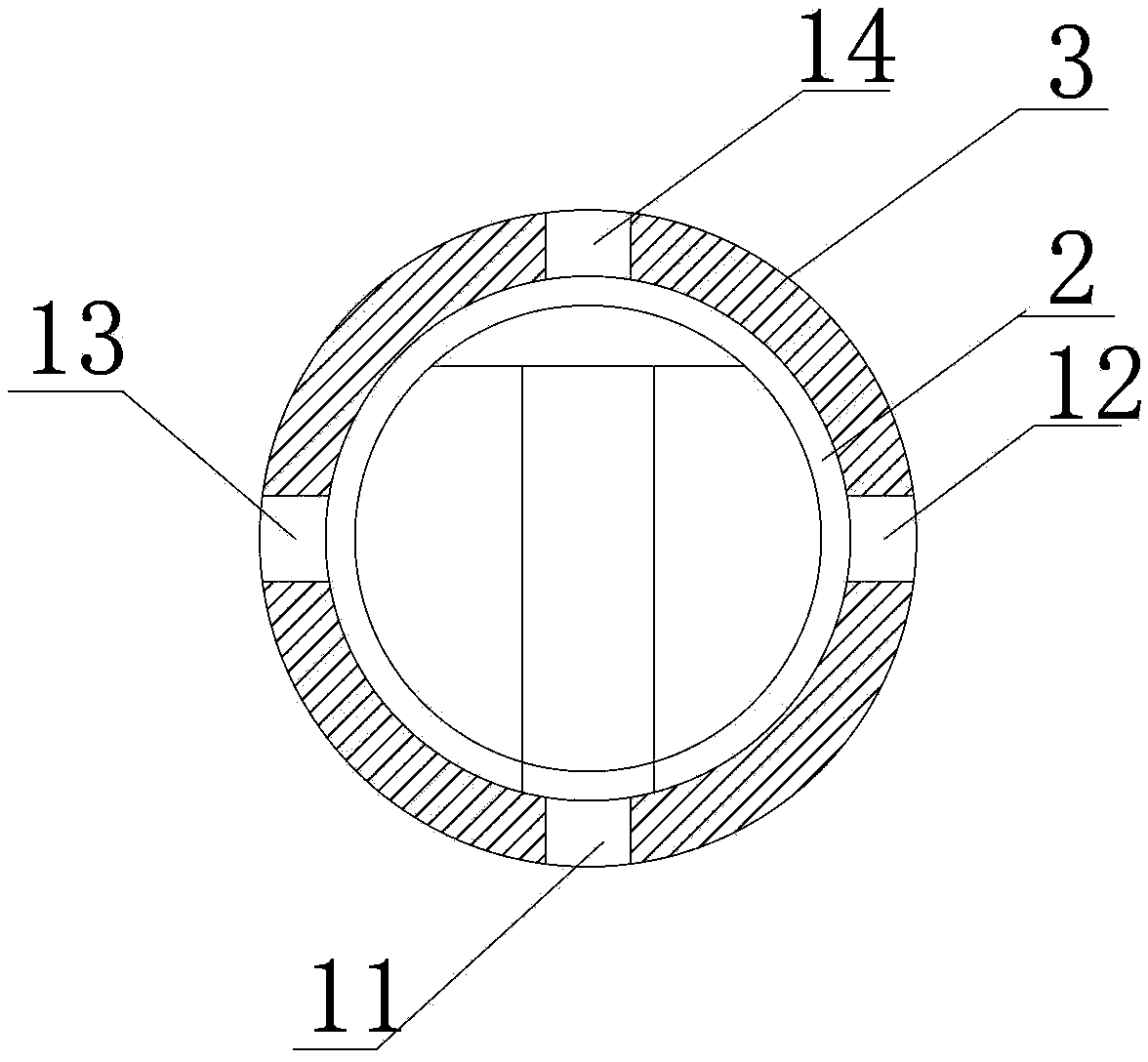

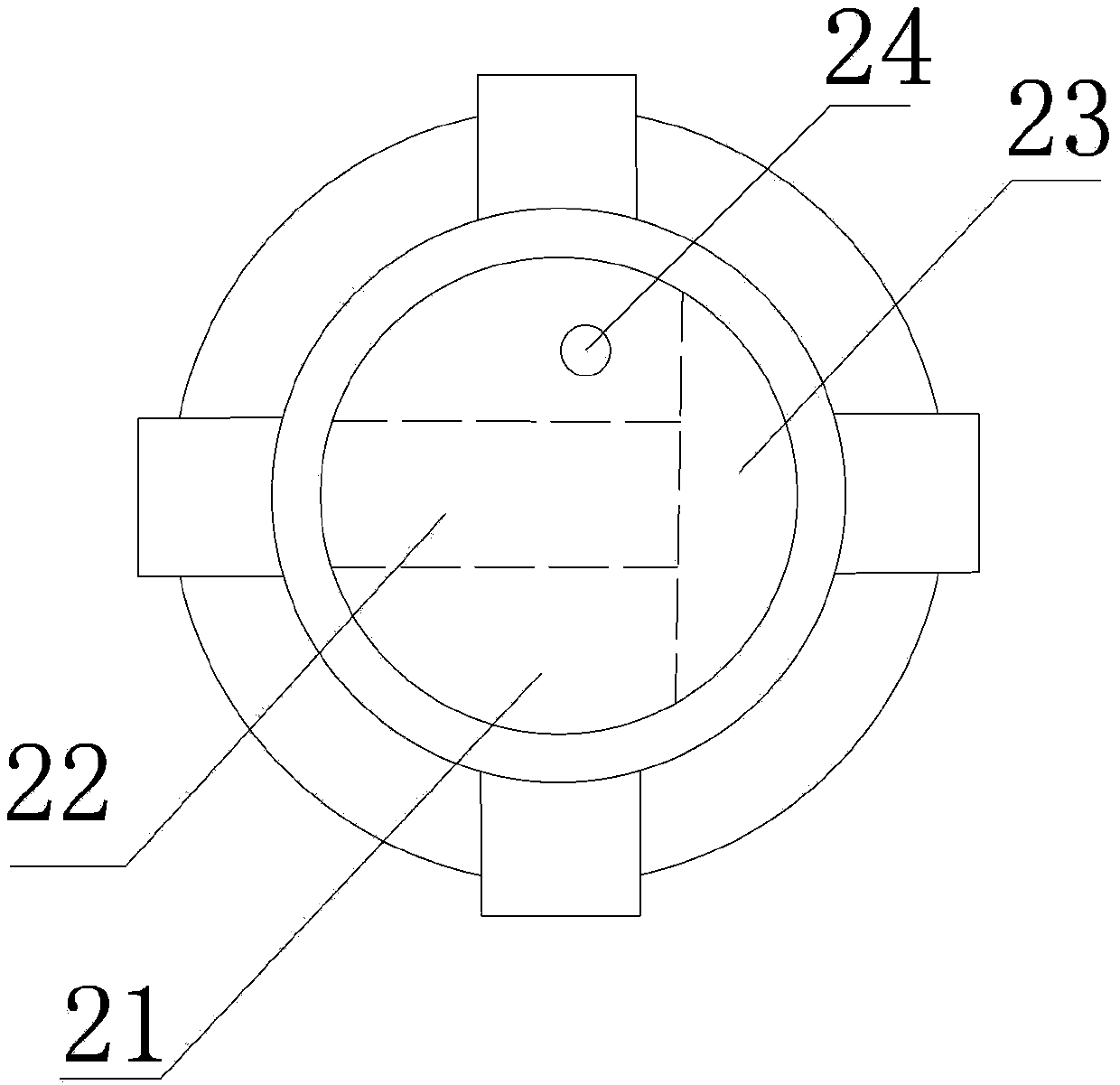

[0026] like figure 2 , image 3 As shown, the valve core 2 is provided with a running water connecting channel 21, a filtering water connecting channel 22, and a drain connecting channel 23. As an improvement of the present invention, a decompressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com