Control method based on gravity compensator

A technology of gravity compensation and control method, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., and can solve the problem that the gas path is difficult to adjust and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

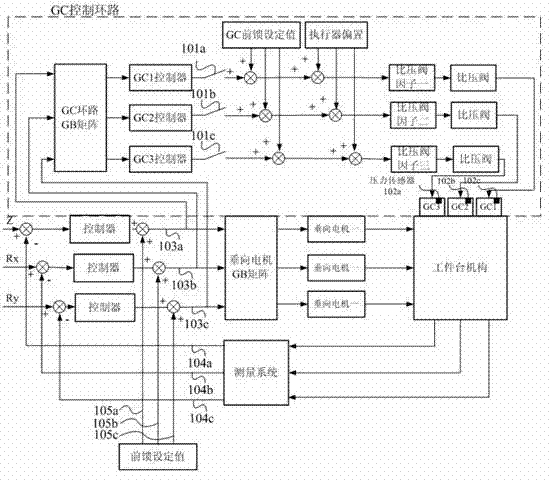

[0043] The invention provides a vertical control method based on a gravity compensator, which can balance the gravity of an object and provide the driving force for the vertical movement of the object in the directions of Z, Rx, and Ry. The gravity compensator is connected with the vertical motor loop Parallel connection, the gravity compensator includes three independent air circuits, the gravity compensator and the vertical motor share three vertical logic axes, the signal is divided into two paths after passing through the logic axes, one path controls the vertical motor, and the other path controls The gravity compensator.

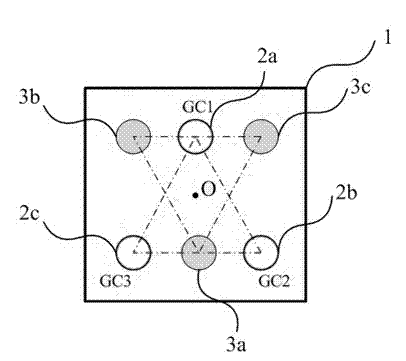

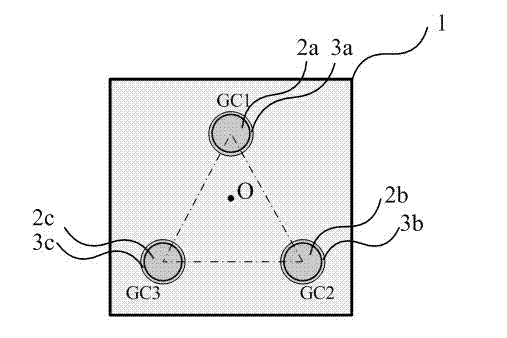

[0044] figure 1 It is a schematic layout diagram of the gravity compensator of the first embodiment of the present invention. Such as figure 1As shown in , the gravity compensator adopts a common air-floating stru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap