Bearing cavity ventilation design method of aero-engine

An aero-engine and design method technology, applied in calculation, special data processing applications, instruments, etc., can solve the problem of calculation, control of engine lubrication system, design and verification of main bearing cavity seal, and failure to obtain engine shaft seal. Questions such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

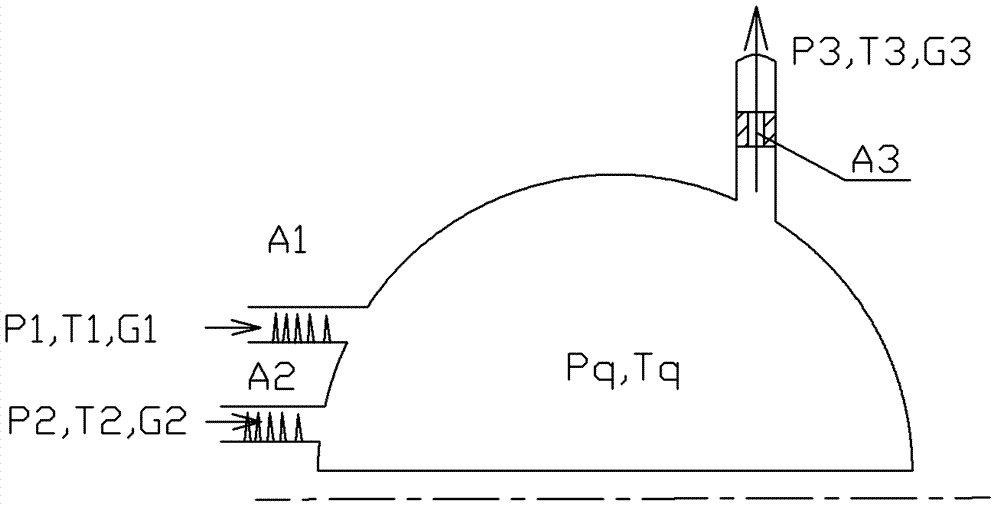

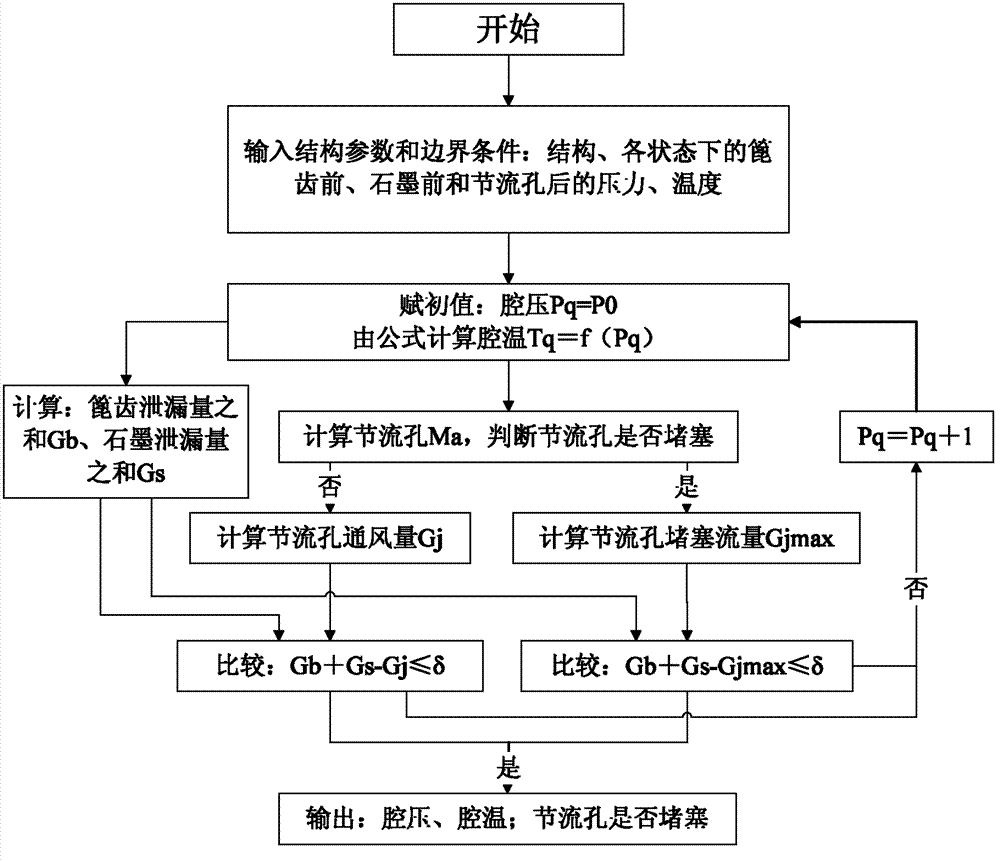

[0093] The invention provides a ventilation design method for an aero-engine bearing cavity, which is characterized in that: the aero-engine bearing cavity ventilation design method involves the basic assumption of throttling ventilation aero-engine bearing cavity, the calculation of the pressure and flow of the throttle hole Method, cavity pressure calculation process.

[0094] Firstly, the boundary parameters of the bearing cavity are obtained. The calculation of the bearing cavity pressure is obtained through multiple iterative joint calculations of the air system and the accessory casing cavity pressure. In each state of the engine corresponding to the flight altitude, calculate the pressure, temperature, and flow rate before sealing of the air system, and use the local atmospheric pressure, high-altitude valve, centrifugal ventilator, etc. to reverse the cavity pressure and cavity temperature of the accessory casing, respectively as the bearing Boundary parameters for cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com