Manufacturing method of radio-frequency connector

A technology of a radio frequency connector and a manufacturing method, which is applied in the manufacture of contacts, assembly/disassembly of contacts, etc., can solve problems such as the reduction of electrical performance, and achieve the effects of improved electrical performance, unchanged impedance, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

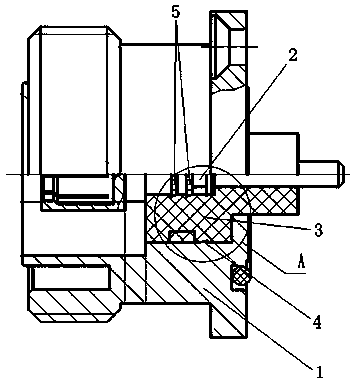

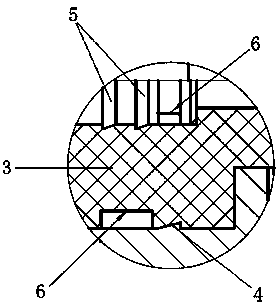

[0019] Such as figure 1 , shown in 2, the manufacture method of radio frequency connector of the present invention, wherein said radio frequency connector comprises outer conductor 1, inner conductor 2 and medium 3; Its steps are:

[0020] (1) Determine the inner protrusion on the inner wall of the outer conductor 1 of the RF connector, that is, the specific position of the inner barb 4;

[0021] (2) Use a machine tool to cut out a groove 6 on the inner conductor that matches the inner barb 4 on the inner wall of the outer conductor 1;

[0022] (3) Determine the outer protrusion on the outer wall of the inner conductor 2 of the RF connector, that is, the specific position of the outer barb 5;

[0023] (4) Use a machine tool to cut out a groove 6 on the medium 3 that matches the outer barb 5 on the outer wall of the inner conductor 2 .

[0024] Using the impedance formula, Z=60 / √εlnD / d, where D represents the inner diameter of the outer conductor 1, d represents the outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com