Four-dimensional ultrasonic probe drive method and device

A technology of ultrasonic probe and driving device, which is applied in the fields of ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, organ movement/change detection, etc., and can solve problems such as different drive motors and obstacles , to achieve the effect of simple control mode and convenient subdivision setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

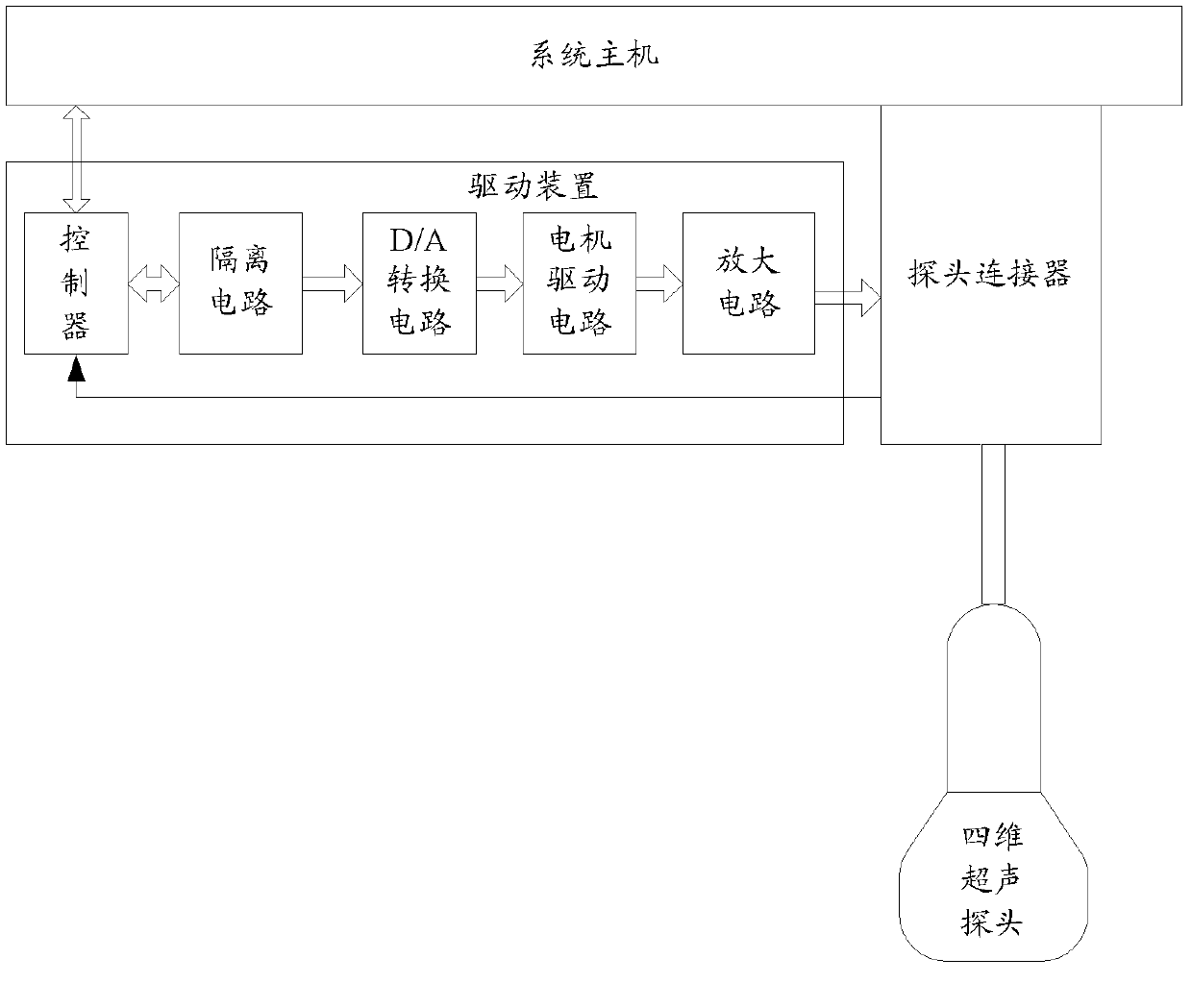

[0025] In order to be applicable to four-dimensional probes from different manufacturers, the present invention proposes a driving method and device for a four-dimensional ultrasonic probe (hereinafter also referred to as a four-dimensional probe). According to different types of four-dimensional ultrasonic probe hosts, the initial value D1 of the counter in the controller is sent through the bus. (the initial value D1 of the counter determines the speed of the motor, changing the initial value D1 of the counter can achieve the variable speed requirement, which will be described in detail below), the number of pulses in the variable speed zone, the number of pulses in the constant speed zone, and output power can be used for different manufacturers. the goal of. Wherein, the initial value D1 of the counter in the controller is determined according to the internal gear ratio GR and the rotational speed of different probes.

[0026] Such as figure 1 As shown, the four-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com