Counter-pull type working platen device for milling machine

A worktable, reverse-pull technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing the number of working steps, complex processing technology, restricting processing continuity, etc., to simplify the fixing method. , optimize the path, improve the effect of processing quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

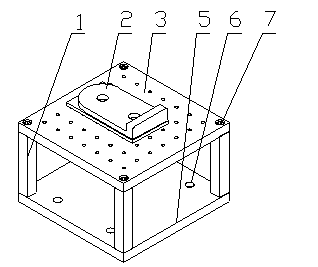

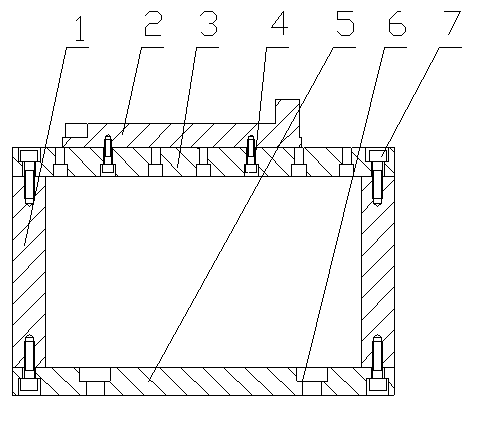

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] Referring to the accompanying drawings, a reverse pull-type workbench device for a milling machine includes a column 1, a reverse pull-type bottom plate 5, and a screw A, and is characterized in that: the four corners of the reverse pull-type bottom plate 5 are provided with screws B7 Four columns 1 are fixedly arranged, and the top of the column 1 is fixedly provided with a pull-back table top 3 , a workpiece 2 is arranged on the pull-back table top 3 , and a threaded blind hole for process is arranged on the reverse side of the workpiece 2 . The anti-pull bottom plate 5 is provided with a counterbore 6 matching the workbench of the milling machine. During specific implementation, the height of the column 1 will ensure that there is enough space to operate the fastening wrench below the reverse-pull table top 3, and the reverse-pull table 3 has a certain thickness, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com