A gel acid system and its preparation for acid fracturing in carbonatite reservoirs

A carbonatite storage and jelly acid technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to effectively reduce the filtration loss of formation conditions, fast reaction speed of acid rock, and limited acid viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] amino acid preparation

[0031] ①Under high-speed stirring, slowly and evenly add the powdered CYY-160 gelling agent into the acid solution. Since the gelling agent is a high-molecular polymer, pay attention to avoid forming lumps (fish eyes), and stir for 2 hours (200ml is a batch);

[0032] ②Let the acid stand for at least 16-24 hours for hydration;

[0033] ③ Add 1% CYY-1 cross-linking agent or first add 1% cross-linking retarder CYY-3 and then add 1% CYY-1 cross-linking agent.

Embodiment 2

[0035] Preparation of finished acid: 20% HCl + 0.8% CYY-160 + 1% CYY-1 cross-linking agent + 1% CYY-3 cross-linking retarder.

[0036] The 6300 reciprocating capillary viscometer of Chandler Company was used to measure the rheological properties of finished acid. The detection principle is: normal temperature -90 ℃ shear rate 40s -1 ;90℃-140℃ shear rate 170s -1 .

[0037] 90℃-140℃, shear rate is 170s -1 test results:

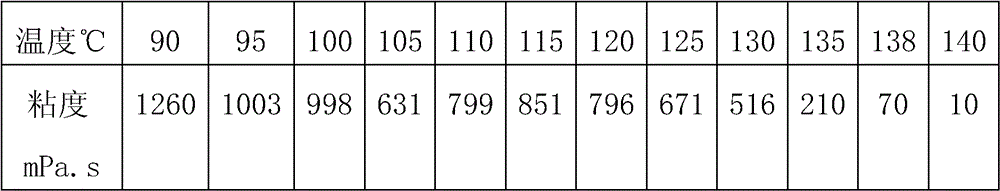

[0038] Table 2-2-9 Viscosity temperature data of formula 190℃-140℃

[0039]

Embodiment 3

[0041] Preparation of finished acid: 20% HCl + 0.8% CYY-160 + 1% CYY-1 cross-linking agent + 1% CYY-3 cross-linking retarder.

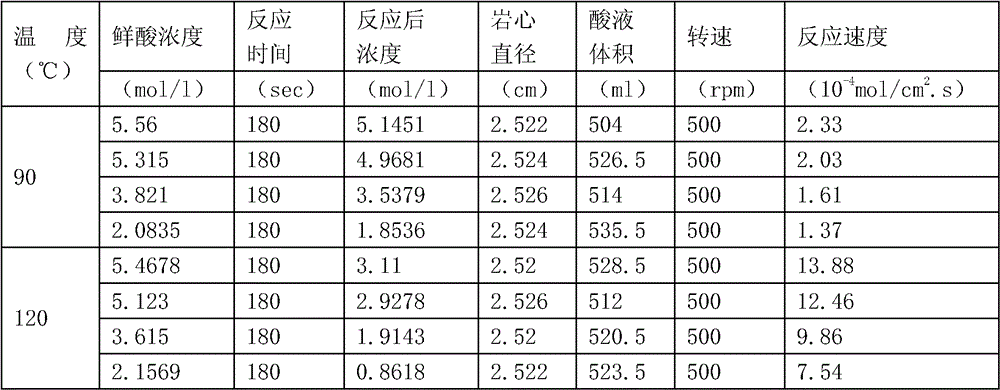

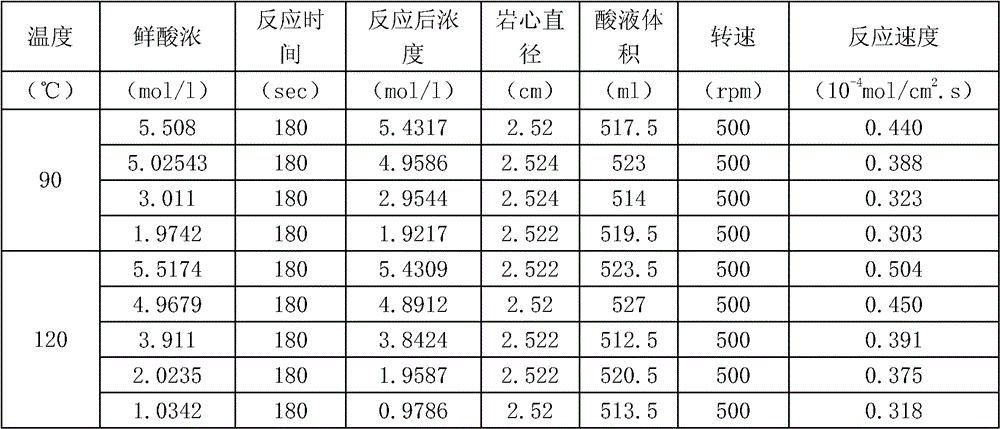

[0042] The reaction rates of common hydrochloric acid and jelly acid were measured with a rotary rock instrument.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com