Ultrasonic measurement

An ultrasonic and workpiece technology, which is applied in the field of ultrasonic measurement devices, can solve the problems of difficulty in measuring the loss of multiple components at the same time, time lag, and different loss rates under test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

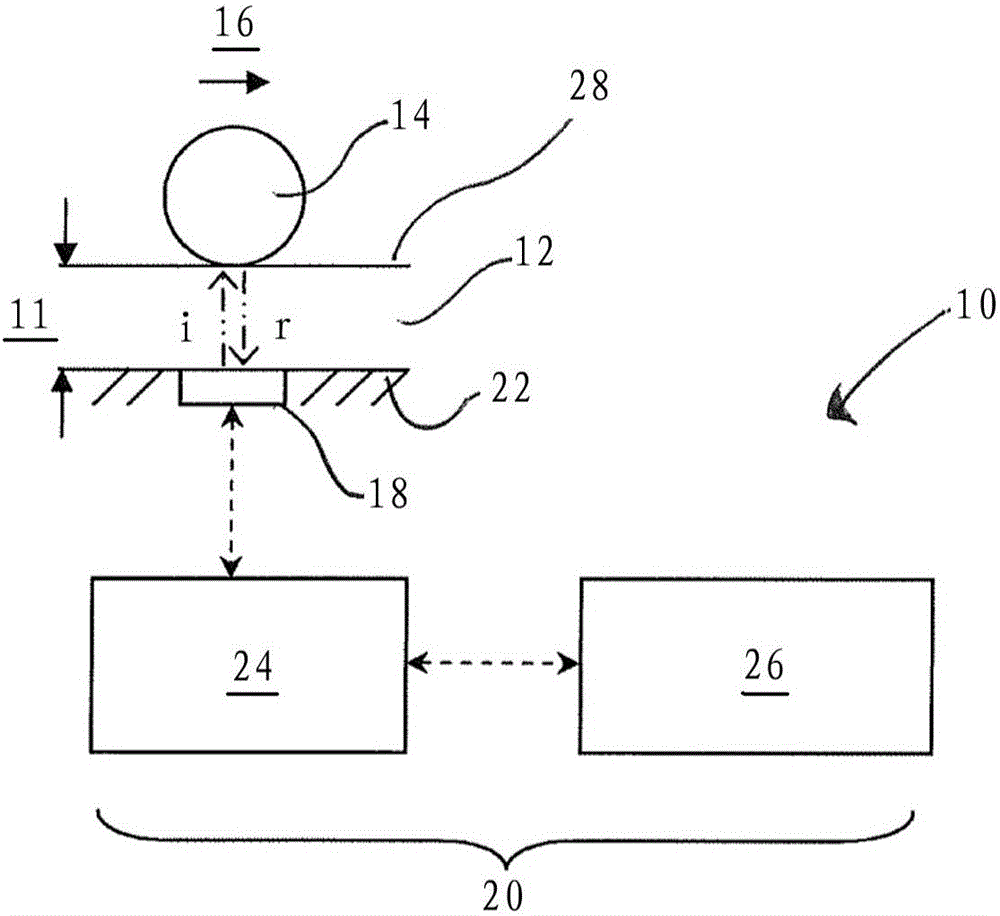

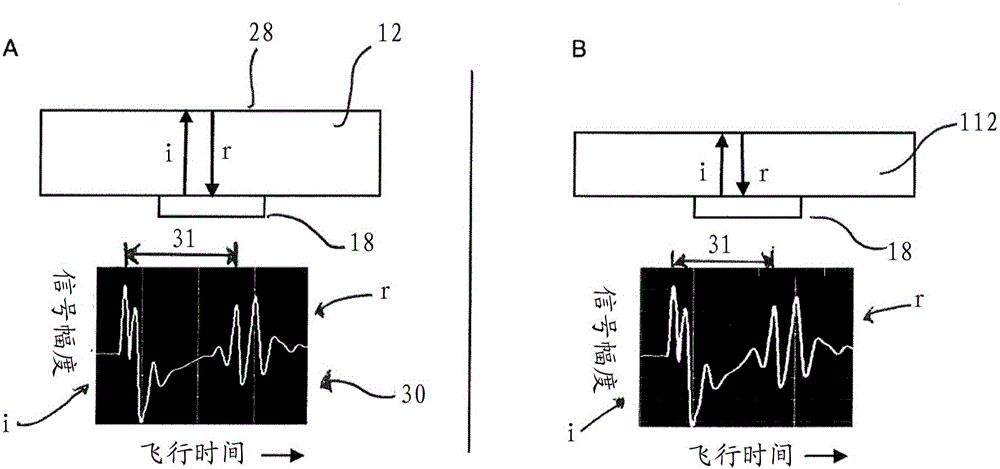

[0045] first reference figure 1 , shows an apparatus for measuring the dimensions of a workpiece 12 using ultrasonic waves.

[0046] Ultrasound refers to the portion of the sound spectrum above human hearing, which is generally considered to include sounds with frequencies in excess of 20 kHz. Ultrasonic pulses pass through the solid at a velocity determined by the solid's material properties. Ultrasonic pulses are usually reflected from interfaces or boundaries when changes in acoustic properties occur.

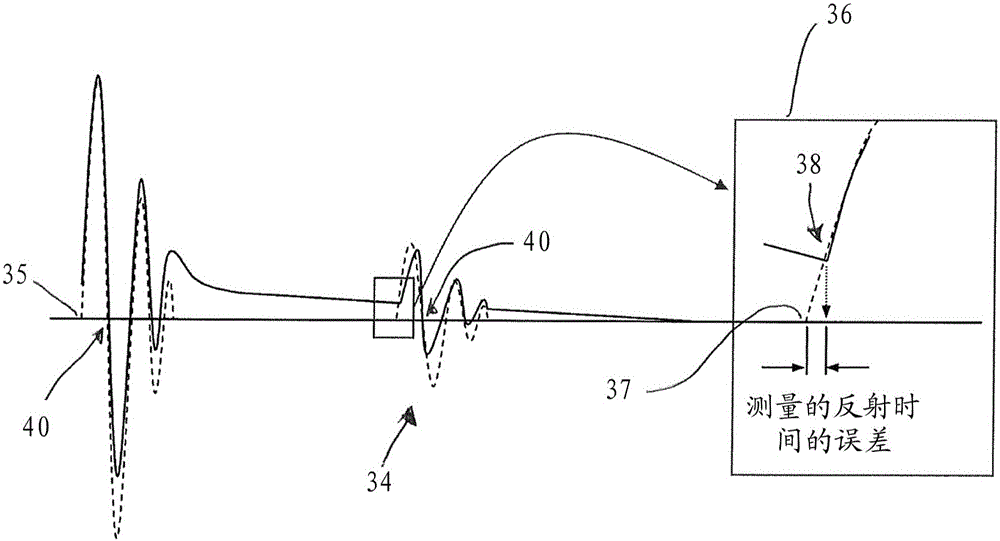

[0047] Ultrasonic signals reflected from a boundary include information about said boundary. For example, by measuring the time it takes for an ultrasonic pulse sent into the workpiece to pass through the workpiece to reach the boundary and return as a reflection, information about the distance to the boundary can be determined. From said measurement time, it is possible (knowing the speed of sound in the material from which the workpiece is made) to calculate the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com