Bidirectional guardrail cleaning vehicle

A guardrail cleaning vehicle, two-way technology, applied in the field of sanitation vehicles, can solve the problems of increasing the failure rate of the guardrail cleaning vehicle, halving the utilization rate of the guardrail cleaning vehicle equipment, and occupying a large space for the guardrail cleaning device, so as to extend the mileage of a single operation , Improve work reliability, improve the effect of vehicle operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

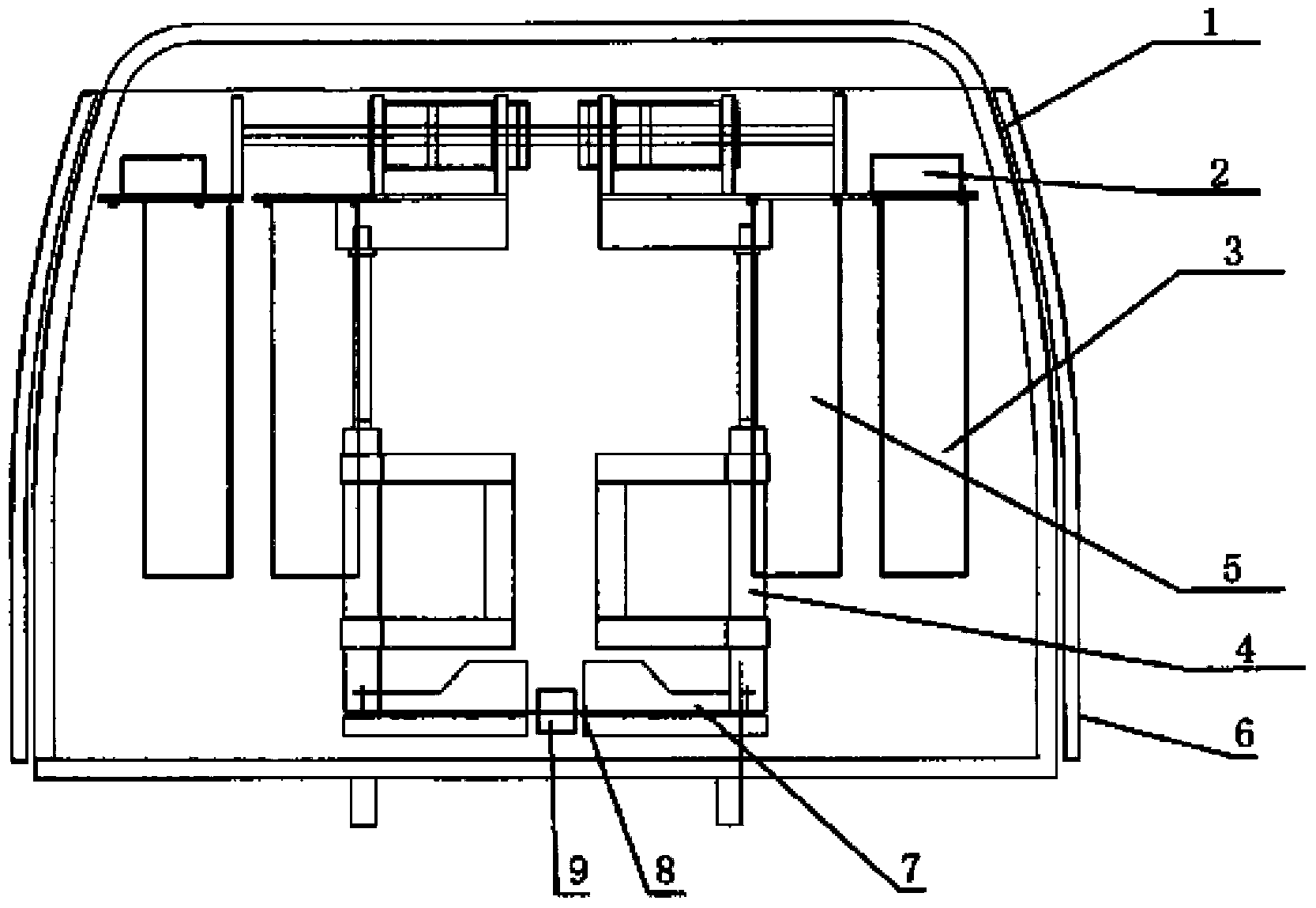

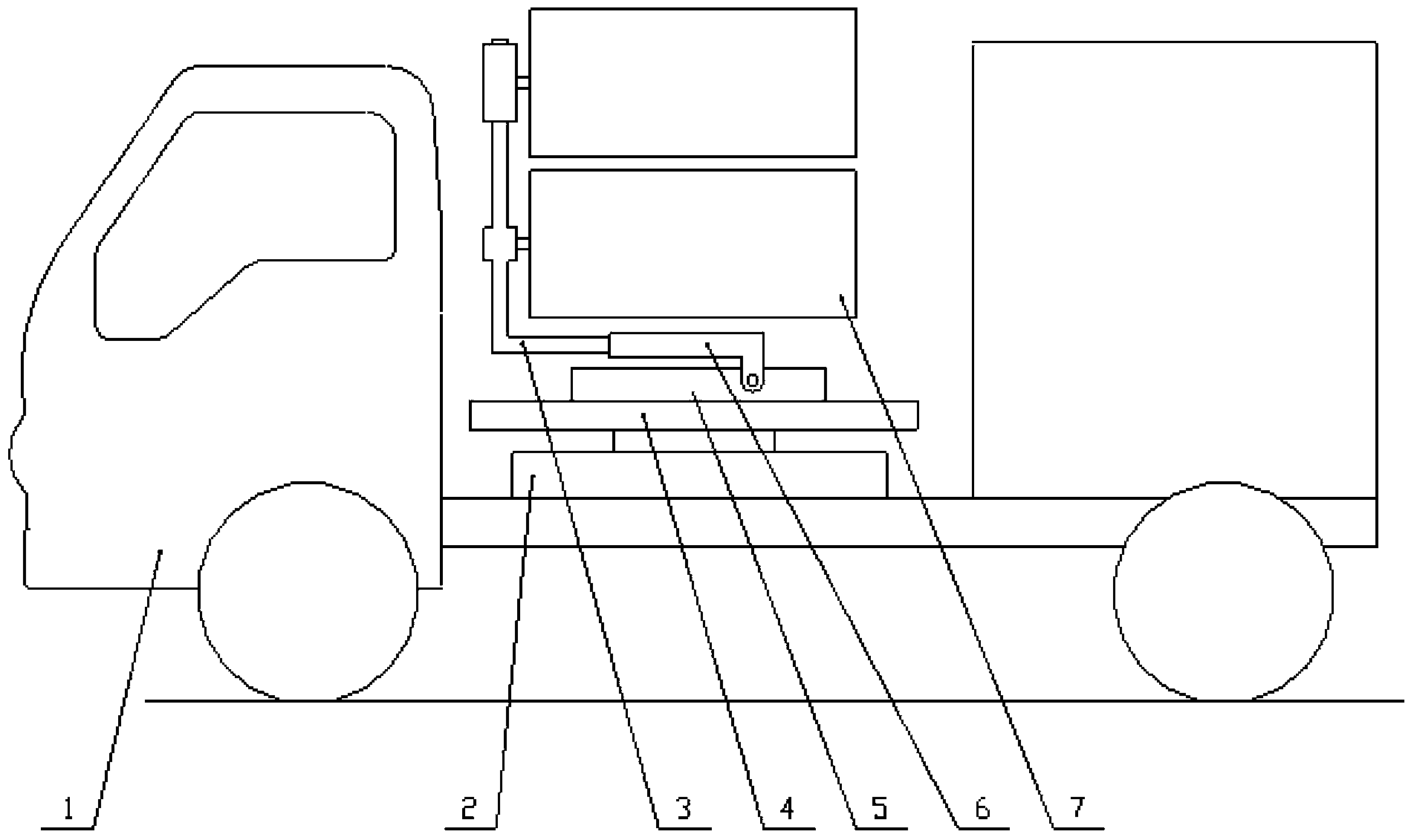

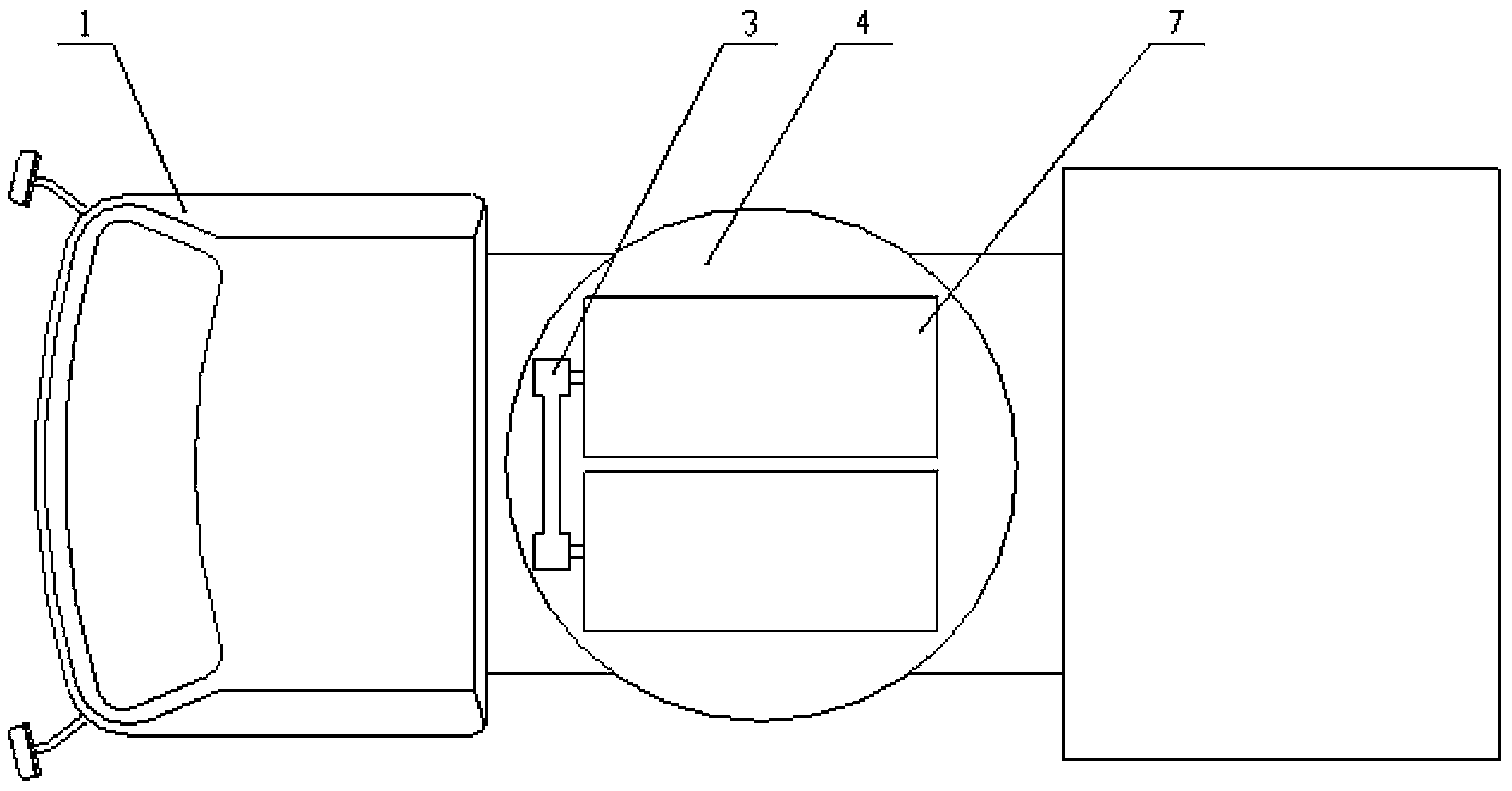

[0040] More preferably, see Figure 2 to Figure 7 As shown, the guardrail cleaning device is installed on the rotary device through a hinged structure, so that the guardrail cleaning device can be rotated around the hinged axis of the hinged structure, and selectively flipped from the position above the turntable to the working ready state position or Return from the position of the working preparation state to the position above the turntable, wherein at the position above the turntable, the guardrail cleaning device is above the turning device, and at the position of the working preparation state at least the guardrail cleaning device The guardrail cleaning parts are outside the side surface of the turntable 4, so as to be able to perform guardrail cleaning operations. Apparently, the guardrail cleaning part of the guardrail cleaning device can generally be a widely used guardrail cleaning brush 7, such as a disc roller brush or a vertical roller brush. In this preferred em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com