Core forming method of non-combustible heat insulation flat plate and manufacturing method of non-combustible heat insulation flat plate

A core material and flat plate technology, applied in chemical instruments and methods, building structures, building components, etc., can solve problems such as difficult handling, increased equipment costs, easy separation of core material blocks, etc., to achieve easy handling and easy transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

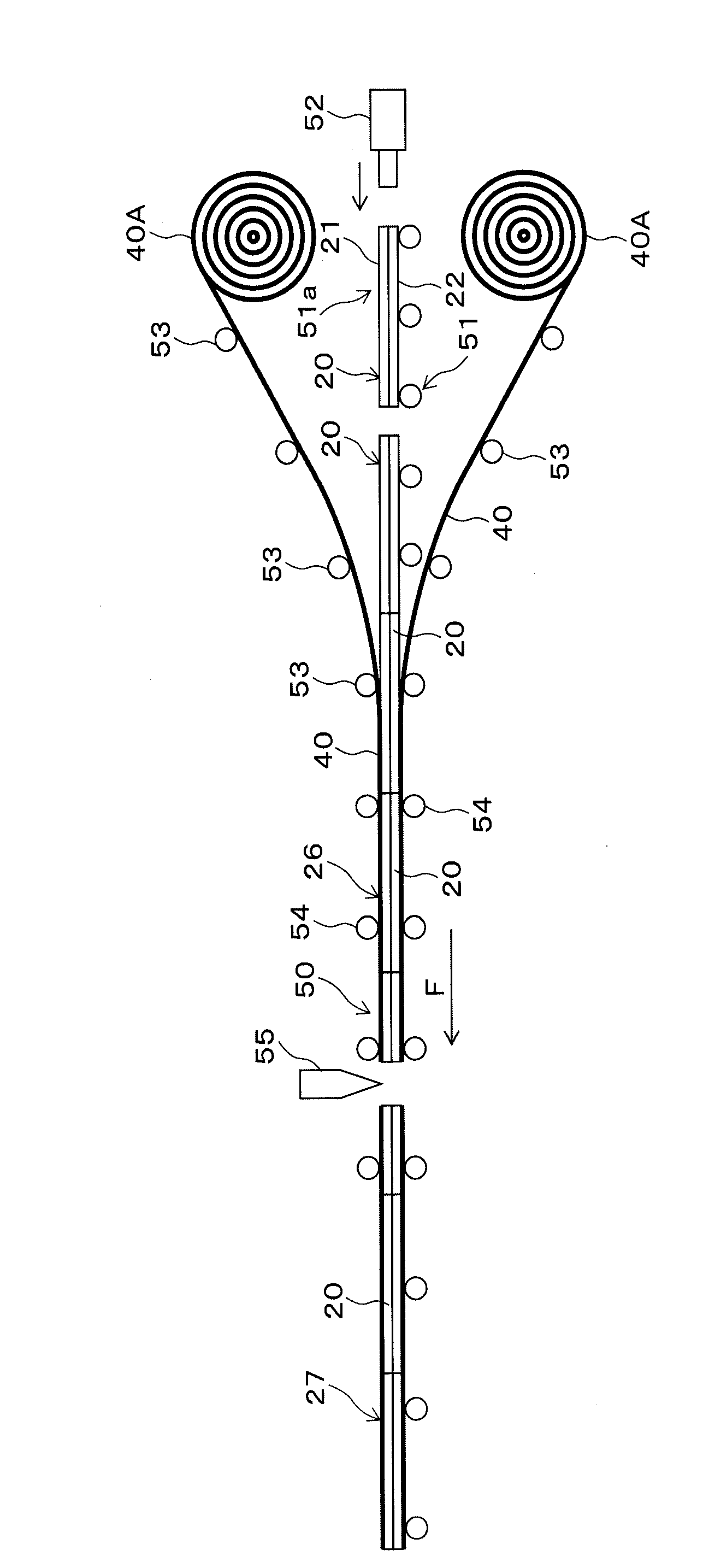

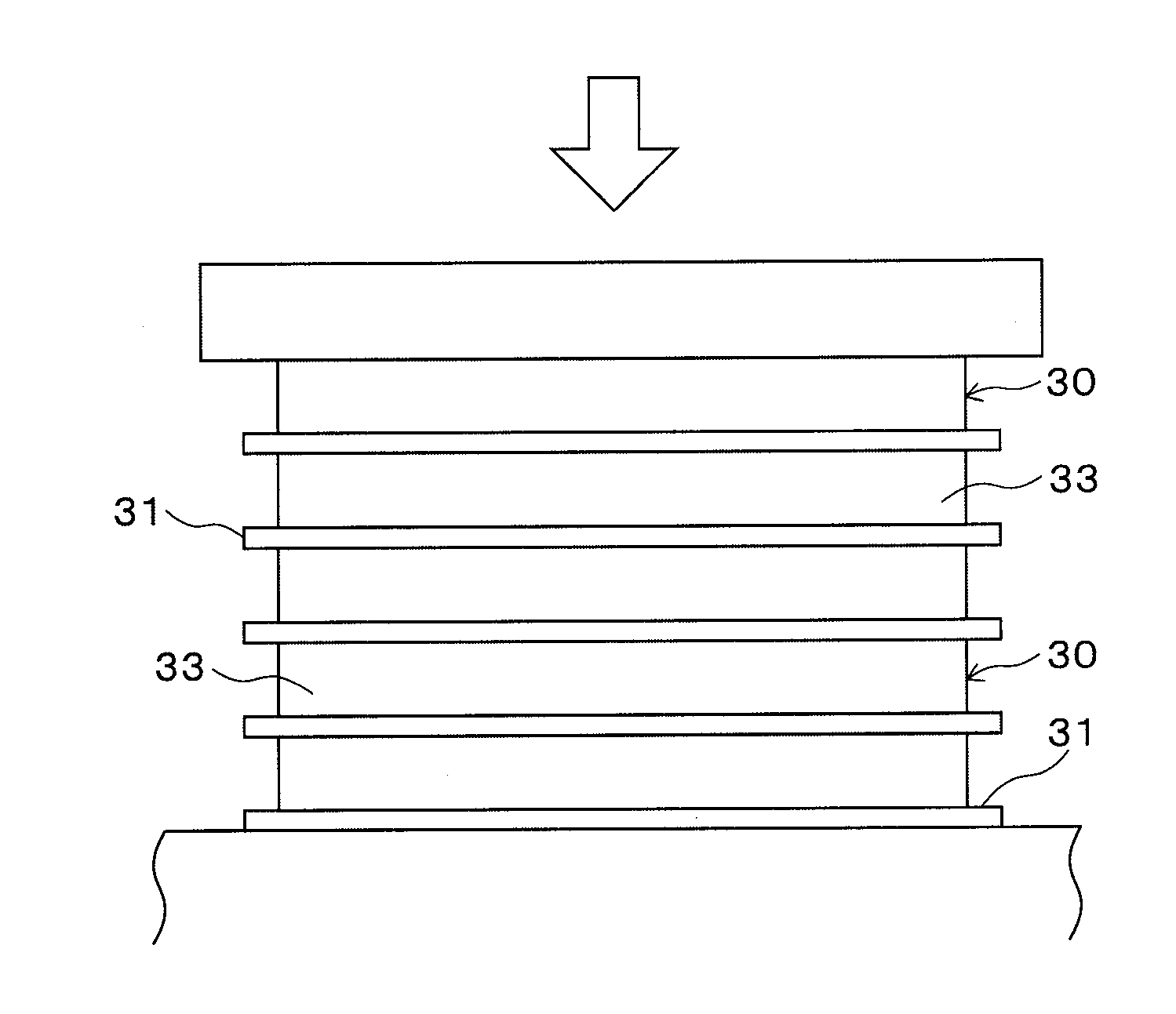

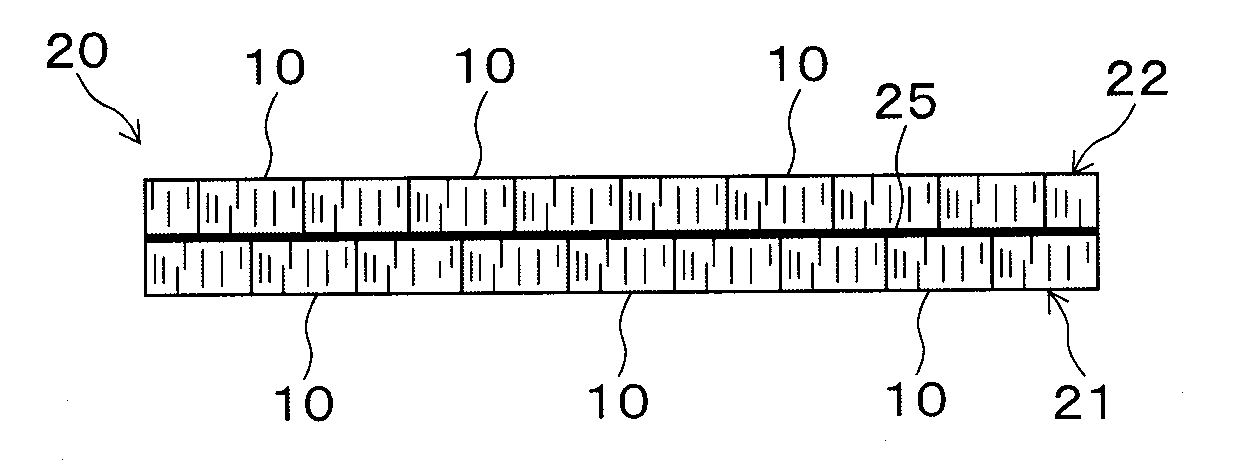

[0037] A method for forming a core material of a non-combustible heat-insulating flat panel and a method for manufacturing a non-combustible heat-insulating flat panel according to an embodiment of the present invention will be described below with reference to the accompanying drawings.

[0038] [1] Core material forming method of non-combustible heat insulating flat panel

[0039] (1) Billet cutting process

[0040] figure 1 Indicates a portion of asbestos blank used as thermal insulation material. The asbestos blank 1 is a strip with a certain width extending along the Y direction. In this case, the fibers 1 mainly extend along the X direction and the Y direction perpendicular to the X direction. In this embodiment, first, a plurality of cutting lines 2 parallel to the X direction are set at equal intervals along the Y direction on the asbestos blank 1 . And the asbestos blank 1 is cut along the cutting line 2 to obtain a plurality of elongated cuboid core blocks 10 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com