A cooling fan

A heat dissipation fan and casing technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of large evaporation loss of lubricating grease and high temperature of bearing parts, so as to reduce manpower consumption, prevent evaporation loss, and quickly Divergent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment, technical solution of the present invention is described further in conjunction with accompanying drawing:

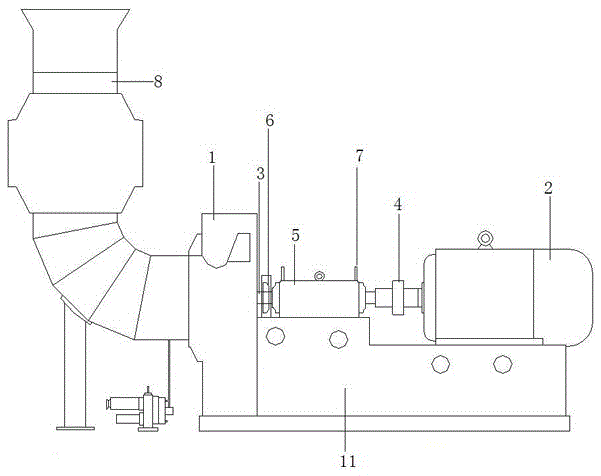

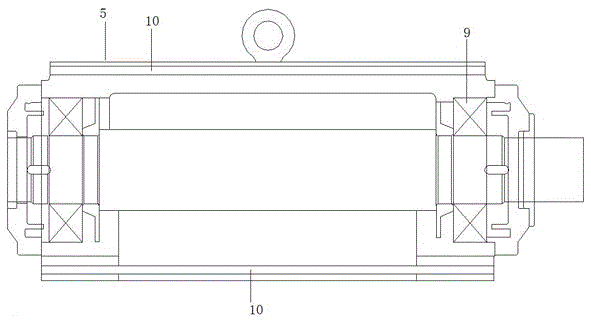

[0017] like figure 1 , figure 2 A kind of sharp cooling fan shown, comprises casing 1, impeller, motor 2, and described impeller is arranged in casing 1, and described casing 1, motor 2 are arranged on base frame 11, and described The casing 1 is provided with an air outlet port and an air inlet port, the impeller is connected with the rotating shaft of the motor 2 through a transmission shaft 3, a bearing 9, and a coupling 4, and the bearing 9 is arranged in a bearing box 5 , the bearing 9 seals the openings at both ends of the bearing box 5 to form a sealed cavity in the bearing box 5, and the sealed cavity is filled with lubricating grease. The impeller is rotated by the mechanical power provided by the motor 2, and the bearing 9 in the transmission part is erected in the bearing box 5, so the vibration of the bearing 9 will be much sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com