Lubricating oil for high temperature resistant powder metallurgy oil bearing and preparation method thereof

A technology of lubricating oil and powder metallurgy for bearings, applied in the field of lubricating oil, can solve the problems of equipment maintenance, maintenance and service life damage, oxidative discoloration of lubricating oil evaporation loss, affecting the service life of equipment, etc., and achieve excellent anti-rust and anti-corrosion problems. , It is not easy to oxidize and deteriorate, and the effect of reducing the maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

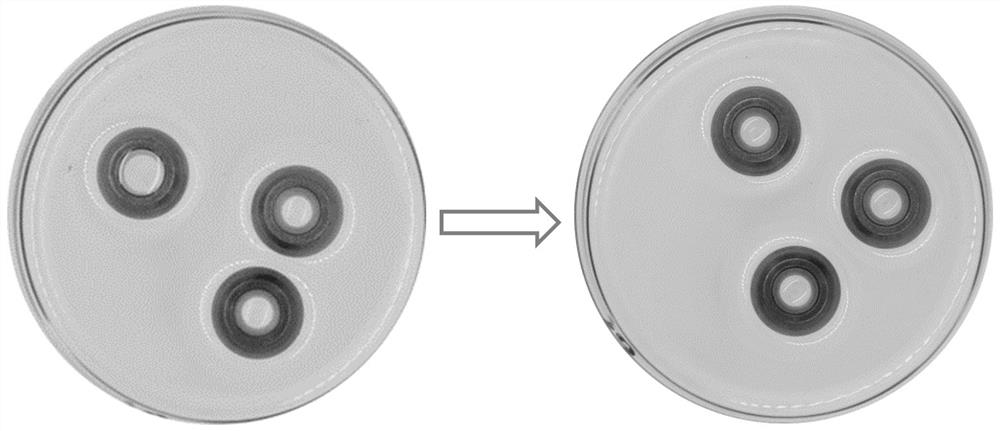

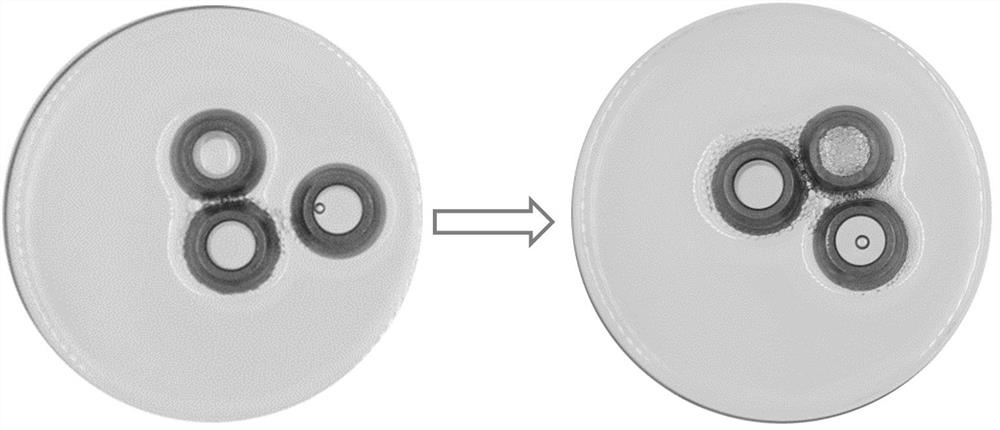

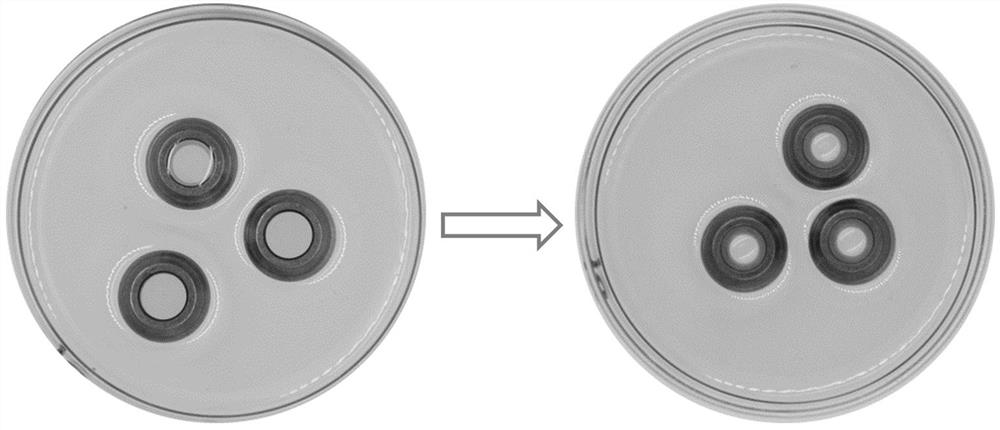

Image

Examples

Embodiment 1

[0051] A lubricating oil for high-temperature-resistant powder metallurgy oil-impregnated bearings, the formula of which is:

[0052] Based on the mass of base oil as 100 parts, where,

[0053] 41 parts of trimethylol propane ester;

[0054] 59 parts of trimellitate;

[0055] 2 parts of polymethacrylate;

[0056] 2 parts of diisooctyl diphenylamine;

[0057] 2 parts of high molecular weight phenol;

[0058] 0.5 part of benzotriazole;

[0059] 0.5 part of triphenyl phosphorothioate;

[0060] 0.01 parts of methyl silicone oil;

[0061] The specific production steps of a high-temperature-resistant powder metallurgy oil-impregnated bearing lubricating oil in this embodiment are as follows:

[0062] Step 1. According to the parts by weight, weigh 41 parts of trimethylolpropane ester and place it in the heating container, control the temperature in the heating container to continuously increase to 90 °C at a heating rate of 8 °C / min, and carry out the process at this temperat...

Embodiment 2

[0068] A lubricating oil for high-temperature-resistant powder metallurgy oil-impregnated bearings, the formula of which is:

[0069] Based on the mass of base oil as 100 parts, where,

[0070] 36 parts of trimethylol propane ester;

[0071] 64 parts of trimellitate;

[0072] 4 parts of polymethacrylate;

[0073] 2 parts of diisooctyl diphenylamine;

[0074] 2 parts of high molecular weight phenol;

[0075] 0.5 part of benzotriazole;

[0076] 0.5 part of triphenyl phosphorothioate;

[0077] 0.01 parts of methyl silicone oil;

[0078] The specific production steps of a high-temperature-resistant powder metallurgy oil-impregnated bearing lubricating oil in this embodiment are as follows:

[0079] Step 1. According to the parts by weight, weigh 36 parts of trimethylolpropane ester and place it in the heating container, control the temperature in the heating container to continuously increase to 80°C at a heating rate of 10°C / min, and carry out the process at this temperatu...

Embodiment 3

[0085] A lubricating oil for high-temperature-resistant powder metallurgy oil-impregnated bearings, the formula of which is:

[0086] Based on the mass of base oil as 100 parts, where,

[0087] 28 parts of trimethylol propane ester;

[0088] 72 parts of trimellitate;

[0089] 8 parts of polymethacrylate;

[0090] 2 parts of diisooctyl diphenylamine;

[0091] 2 parts of high molecular weight phenol;

[0092] 0.5 part of benzotriazole;

[0093] 0.5 part of triphenyl phosphorothioate;

[0094] 0.01 parts of methyl silicone oil;

[0095] The specific production steps of a high-temperature-resistant powder metallurgy oil-impregnated bearing lubricating oil in this embodiment are as follows:

[0096] Step 1. According to the parts by weight, weigh 28 parts of trimethylolpropane ester and place it in a heating container, control the temperature in the heating container to continuously increase to 85°C at a heating rate of 5°C / min, and carry out the process at this temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com