Yarn tension detector

A yarn tension and detector technology, applied in the textile field, can solve the problems of yarn breakage, contamination, yarn knots, etc., and achieve the effects of preventing breakage, preventing damage, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

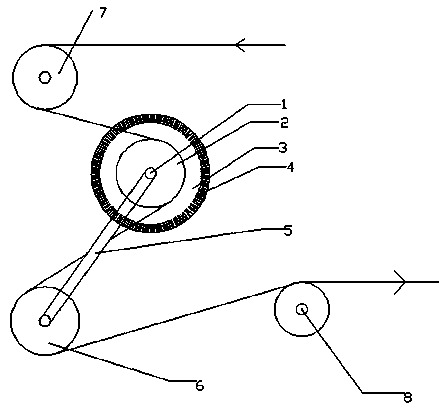

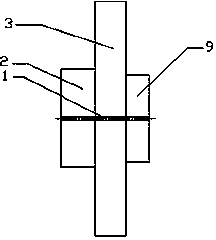

[0017] Such as figure 1 with 3 As shown, the yarn tension detector includes a fixed guide wheel 2, a fixed shaft rod 1, a tension wheel 6, a tension connecting rod 5, a scale wheel 3, and a rotation sensor 9, wherein the fixed guide wheel 2, the scale wheel 3 and the rotation sensor 9 is coaxially installed on the fixed shaft rod 1, wherein the fixed guide wheel 2 can rotate on the fixed shaft rod 1, while the fixed end of the scale wheel 3 and the rotation sensor 9 are fixed on the fixed shaft rod 1, and the tension link 5 is fixedly connected with the rotation sensing end of the rotation sensor 9, the other end of the tension link 5 is provided with a tension wheel 6, and scales 4 are evenly distributed on the scale wheel 3.

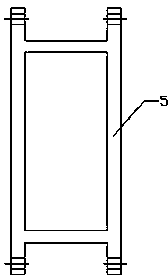

[0018] Such as figure 2 As shown, the tension link is a duplex structure, with holes for connecting with the shaft at both ends, and a rectangular wire slot in the middle.

[0019] When using as figure 1 As shown, the yarn is transmitted to the ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com