Rotary connection and internal wire bending test device

A bending test and rotary connection technology, applied in the field of testing and testing machines, can solve problems such as increasing work intensity, increasing operation difficulty, and reducing work efficiency, and achieves the effects of reducing labor intensity, reducing operation difficulty, and improving test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

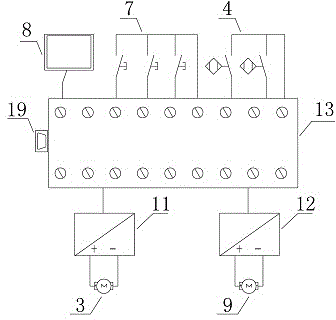

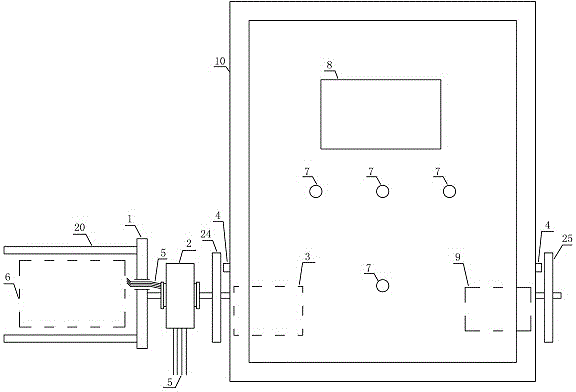

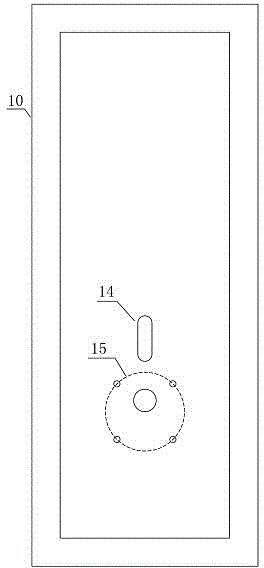

[0020] Accompanying drawing is a kind of specific embodiment of the present invention.

[0021] The rotary connection and internal wire bending test device of the present invention includes a programmable controller 13 and a motor installed in the casing 10, and a fixing fixture 1 that is positioned outside the casing and is installed on the output shaft of the motor to fix the device under test. Requirements, programmable controller 13 is connected to control the speed, rotation angle, and number of rotations of the motor; use the man-machine interface 8 or computer monitoring to realize parameter selection, parameter modification and start and stop control of the device, and the man-machine interface 8 is directly connected to the programmable The controller 13 and the computer are connected to the programmable controller through the serial communication port 19. The specific structure of the experimental device is as follows.

[0022] (1) This device has the detection and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com