A device and method for removing bobbin tail

A bobbin and tail yarn technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, can solve the problems of increasing labor intensity, not removing the tail yarn, and reducing work efficiency, so as to reduce labor intensity, The effect of improving feeding efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

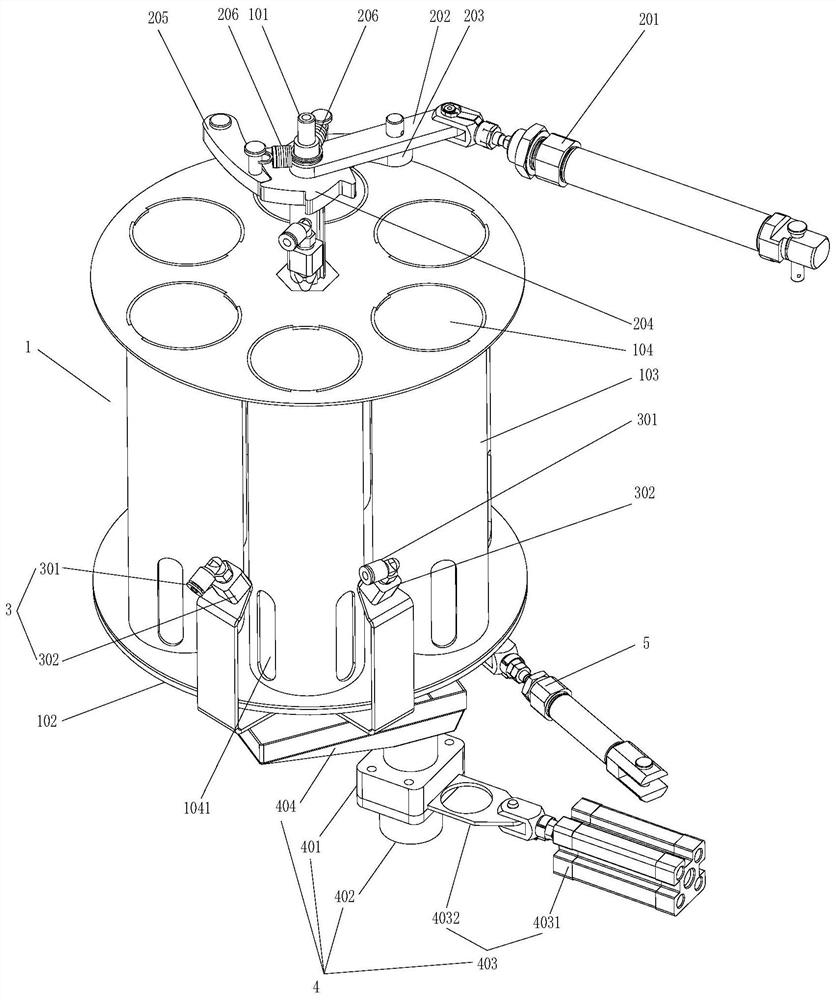

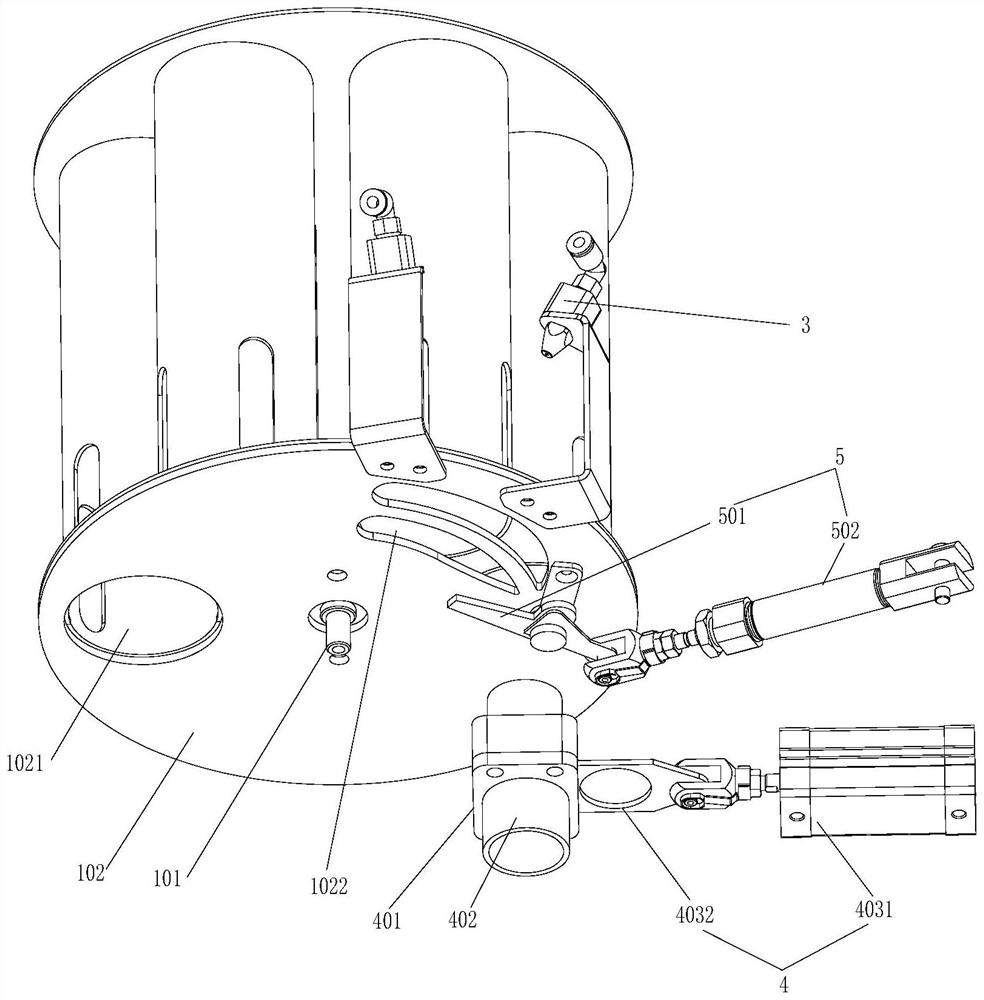

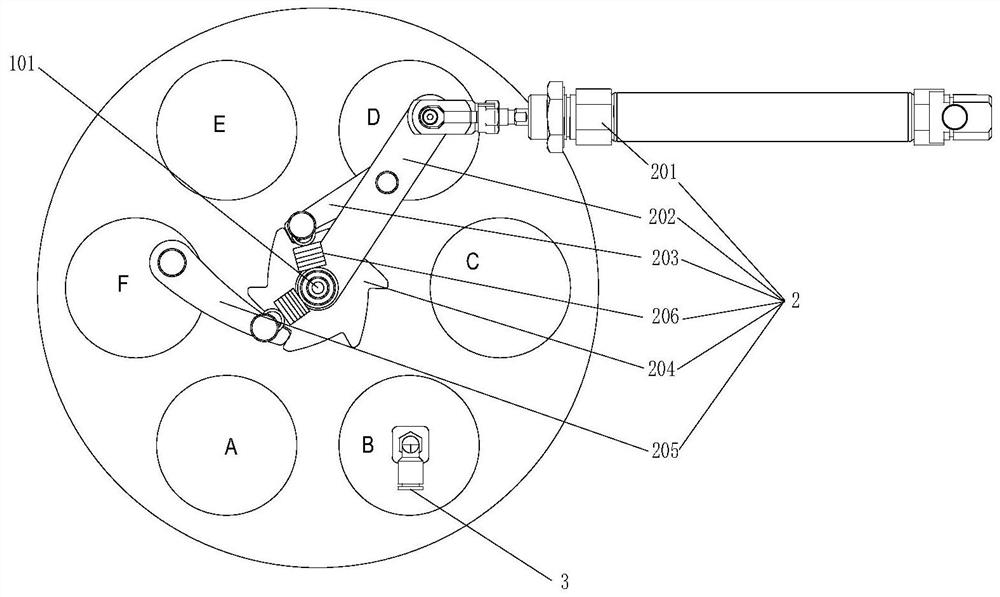

[0034] like figure 1 As shown, a device for removing cop tail yarn according to an embodiment of the present invention includes a base body 1 , a rotating device 2 , an air blowing device 3 , a negative pressure device 4 and a shearing device 5 . The rotating device 2 is connected to the base body 1 . The base body 1 holds the cops. The rotating device 2 is used to drive the base body 1 to rotate. The blowing device 3 is used to blow out the tail yarn of the cop located in the base body 1 . The negative pressure device 4 is used for adsorbing the tail yarn blown out by the air blowing device 3 . The shearing device 5 is used for shearing the tail yarn blown out by the air blowing device 3 .

[0035] In the above-mentioned embodiment, before the cop is put into the empty storage space of the yarn magazine, the tail yarn of the cop is cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com