Lithium battery electrode sheet cleaning device and method

A technology of cleaning device and surface cleaning device, which is applied to cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. The effect of reducing self-discharge rate, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

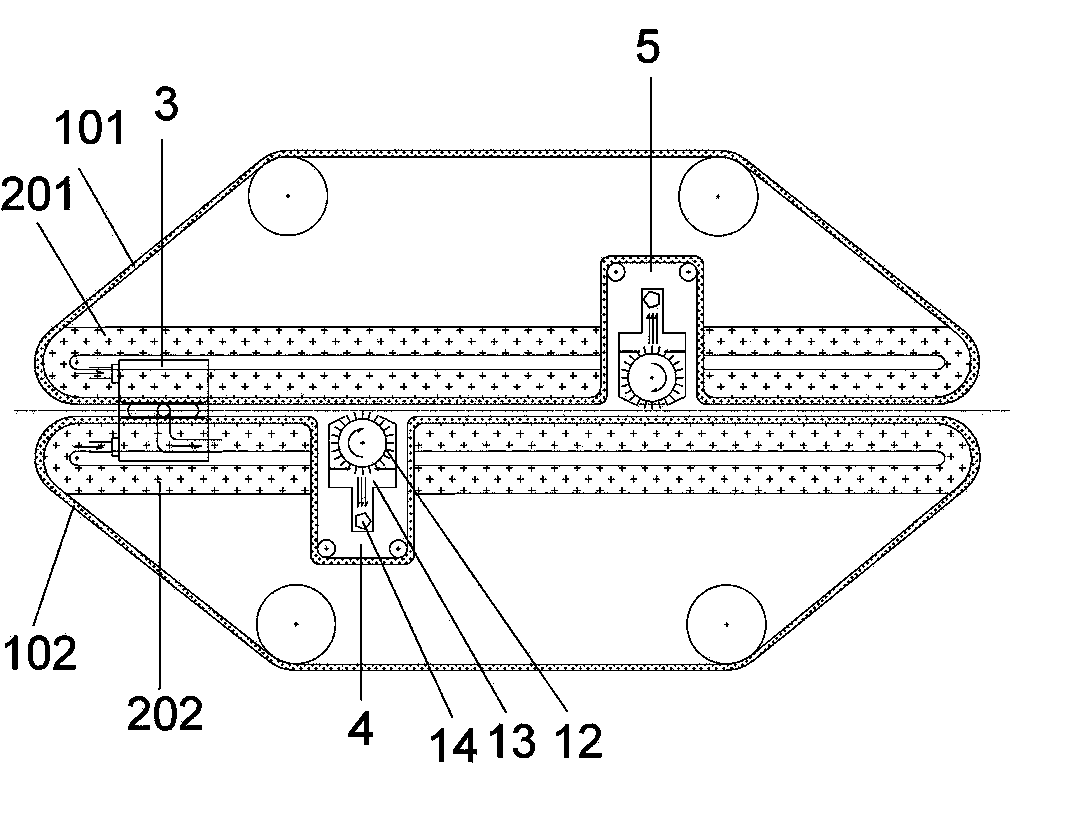

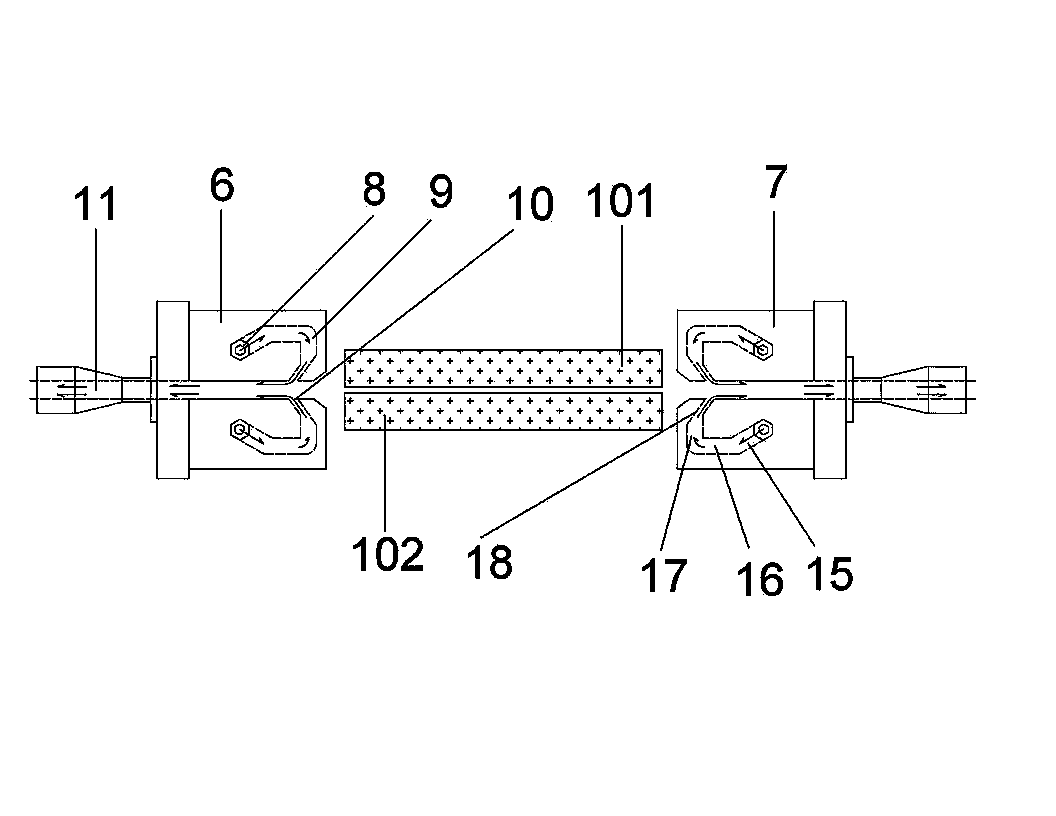

[0023] Embodiment one: iffigure 1 As shown, a lithium battery electrode sheet cleaning device includes an upper adsorption conveyor belt 101, a lower adsorption conveyor belt 102, an upper vacuum adsorption plate 201, a lower vacuum adsorption plate 202, an edge cleaning device 3, a lower surface cleaning device 4 and an upper surface cleaning device. Device 5, the edge cleaning device 3 is symmetrical up and down, the upper part of the edge cleaning device 3 is placed on the upper adsorption conveyor belt 101, the lower part of the edge cleaning device 3 is placed on the lower adsorption conveyor belt 102, and the lower surface cleaning device 4 is placed on the lower adsorption conveyor belt 102, the upper surface cleaning device 5 is placed on the upper adsorption conveyor belt 101, and the upper vacuum adsorption plate 201 and the lower vacuum adsorption plate 202 are respectively installed inside the upper adsorption conveyor belt 101 and the lower adsorption conveyor belt ...

Embodiment 2

[0025] Embodiment two: if figure 1 As shown, a lithium battery electrode sheet cleaning device includes an upper adsorption conveyor belt 101, a lower adsorption conveyor belt 102, an upper vacuum adsorption plate 201, a lower vacuum adsorption plate 202, an edge cleaning device 3, a lower surface cleaning device 4 and an upper surface cleaning device. Device 5, the edge cleaning device 3 is symmetrical up and down, the upper part of the edge cleaning device 3 is placed on the upper adsorption conveyor belt 101, the lower part of the edge cleaning device 3 is placed on the lower adsorption conveyor belt 102, and the lower surface cleaning device 4 is placed on the lower adsorption conveyor belt 102, the upper surface cleaning device 5 is placed on the upper adsorption conveyor belt 101, and the upper vacuum adsorption plate 201 and the lower vacuum adsorption plate 202 are respectively installed inside the upper adsorption conveyor belt 101 and the lower adsorption conveyor bel...

Embodiment 3

[0027] Embodiment three: as figure 1 As shown, a lithium battery electrode sheet cleaning device includes an upper adsorption conveyor belt 101, a lower adsorption conveyor belt 102, an upper vacuum adsorption plate 201, a lower vacuum adsorption plate 202, an edge cleaning device 3, a lower surface cleaning device 4 and an upper surface cleaning device. Device 5, the edge cleaning device 3 is symmetrical up and down, the upper part of the edge cleaning device 3 is placed on the upper adsorption conveyor belt 101, the lower part of the edge cleaning device 3 is placed on the lower adsorption conveyor belt 102, and the lower surface cleaning device 4 is placed on the lower adsorption conveyor belt 102, the upper surface cleaning device 5 is placed on the upper adsorption conveyor belt 101, and the upper vacuum adsorption plate 201 and the lower vacuum adsorption plate 202 are respectively installed inside the upper adsorption conveyor belt 101 and the lower adsorption conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com