Integrated riveting device and integrated riveting method of large-scale cylinder section component

A riveting device and large-scale cylinder technology, applied in the field of advanced aerospace manufacturing, can solve the problems of weak rigidity of the workpiece, prolong production cycle, long processing cycle, etc., achieve the effect of reducing rotation torsion deformation, ensuring shape accuracy, and realizing noise processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

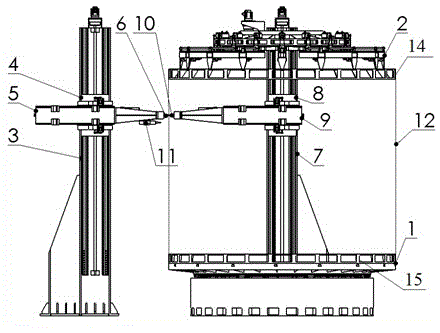

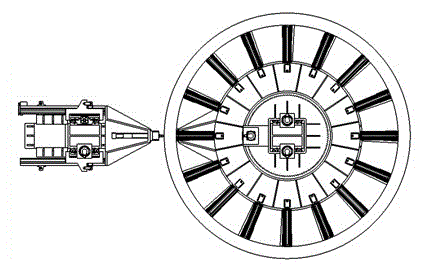

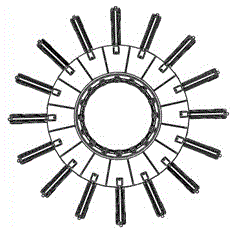

[0028] like Figure 1 to Figure 5 As shown, the overall riveting device of the large-scale cylindrical member of the present invention mainly includes a rotary table 1, a flexible top liftable clamping system 2, a numerically controlled servo flexible support system 13, a nail feeding device 6, a drilling system 11, and a riveting device 10 , left column 3, left sliding saddle 4, left sliding plate 5, right column 7, right sliding saddle 8, right sliding plate 9, upper positioning tooling part 14, lower positioning tooling part 15; the upper end of at least one workpiece 12 passes through an upper positioning tooling Part 14 is installed on the top liftable flexible clamping system 2; the lower end of the workpiece 12 is installed on the rotary table 1 through a lower positioning too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com