Processing method of chemical centrifugal pump shaft

A processing method and centrifugal pump technology are applied in the processing field of industrial pump accessories, which can solve the problems of low production efficiency, difficult to guarantee the precision of dimensional, geometric and position tolerances, and low processing precision, and achieve convenient processing, improve production efficiency, and ensure processing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

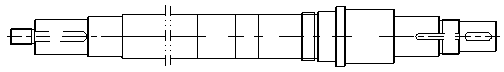

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

[0015] Referring to the accompanying drawings, the processing method of the chemical centrifugal pump shaft is characterized in that it includes the following steps: 1) Drilling the center hole: clamp the outer circle of the blank with a three-jaw chuck, and drill the center holes at both ends of the shaft with a center drill; 2) ), Rough turning: Use the chuck of the machine core to top the shaft, leave a machining allowance of 0.2mm for each outer circle of the rough turning, and keep a machining allowance of 1mm for the length of each step of the rough turning; 3), quenching and tempering treatment; 4), Finish turning: use the movement chuck to jack the shaft well, the largest outer circle on the finish turning shaft meets the requirements of the drawing, the various threads of the finish turning meet the requirements of the drawing, the length of each step of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com