High-temperature online sterilizer rolling barrel

A sterilizer and drum technology, applied in the field of machine drums, can solve problems such as machine wear, sharp increase in energy consumption, prone to machine failures, long fuselage and production costs, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

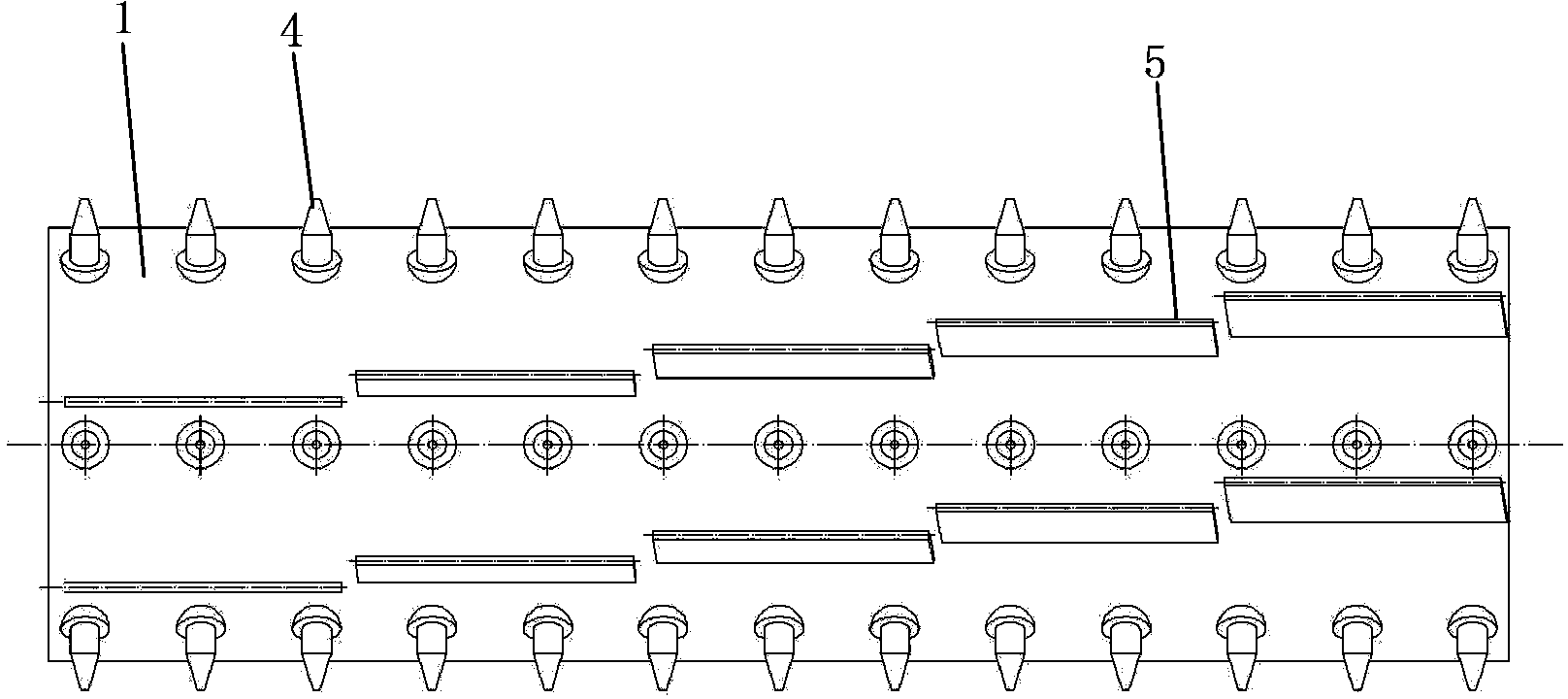

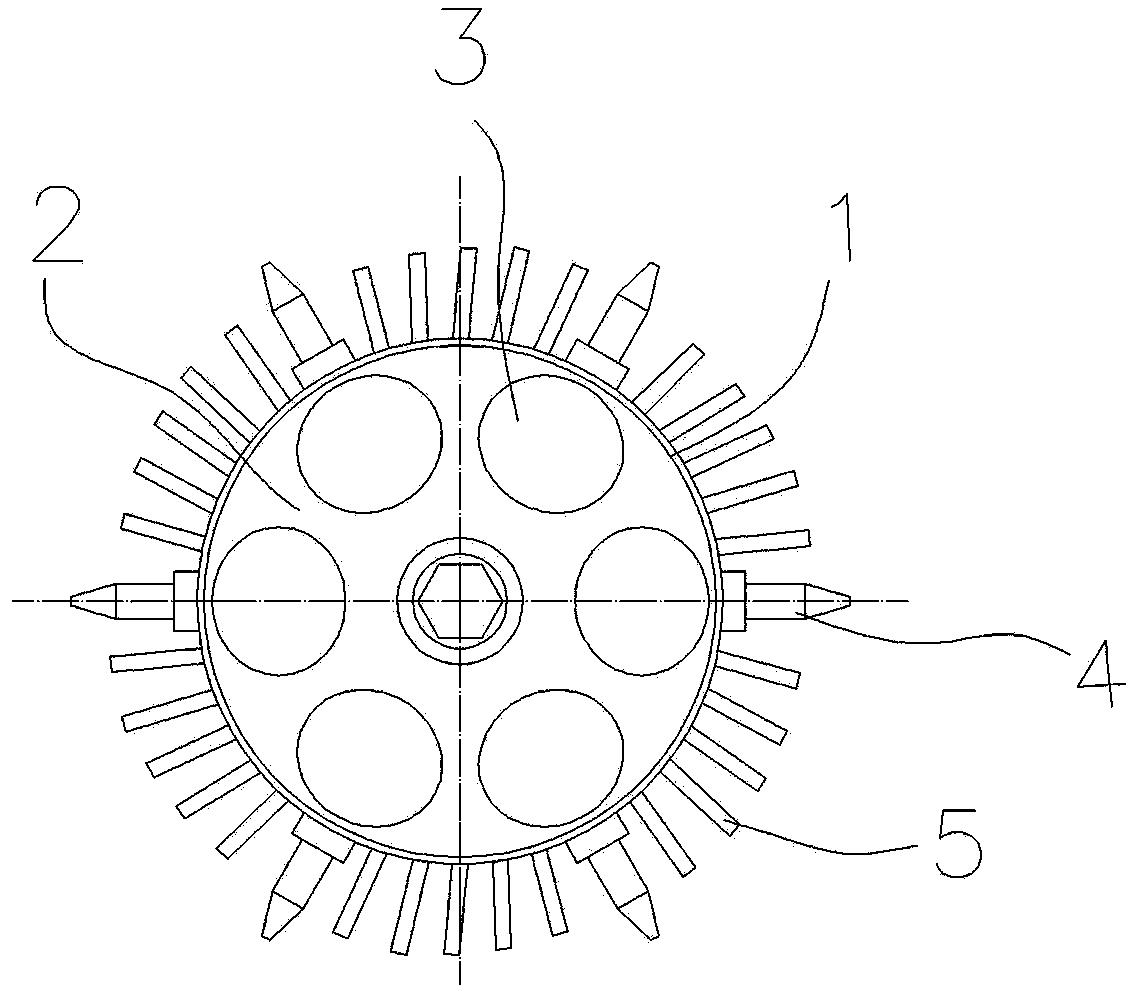

[0013] Such as figure 1 , as shown in Figure 2, a high-temperature online sterilizer drum, which includes a drum 1, the two ends of the drum 1 are respectively provided with a hub 6 and a connected web 2, it is characterized in that: the outer cylindrical surface of the drum 1 is There are crushing nails 4 arranged in rows and rows in the circumferential direction and the axial direction; scrapers 5 arranged in rows and rows are arranged on the outer cylindrical surface of the drum 1 along the circumferential direction and the axial direction.

[0014] This design of setting the crushing nail 4 and the scraper 5 on the outer cylindrical surface of the drum 1 at the same time solves the problem of the long machine body caused by the front and rear arrangement of the crushing nail 4 and the tilling device in the prior art, and realizes The miniaturization of the machine reduces the production cost.

[0015] The crushing nails 4 are evenly arranged in rows and columns on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com