Method for preparing catalyst for hydrogenating pyridine compound and application thereof

A compound and catalyst technology, which is applied in the field of preparation of catalysts for hydrogenation of pyridine compounds, can solve problems such as low yield and harsh reaction conditions, and achieve the effects of high product conversion rate, easy availability of raw materials, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

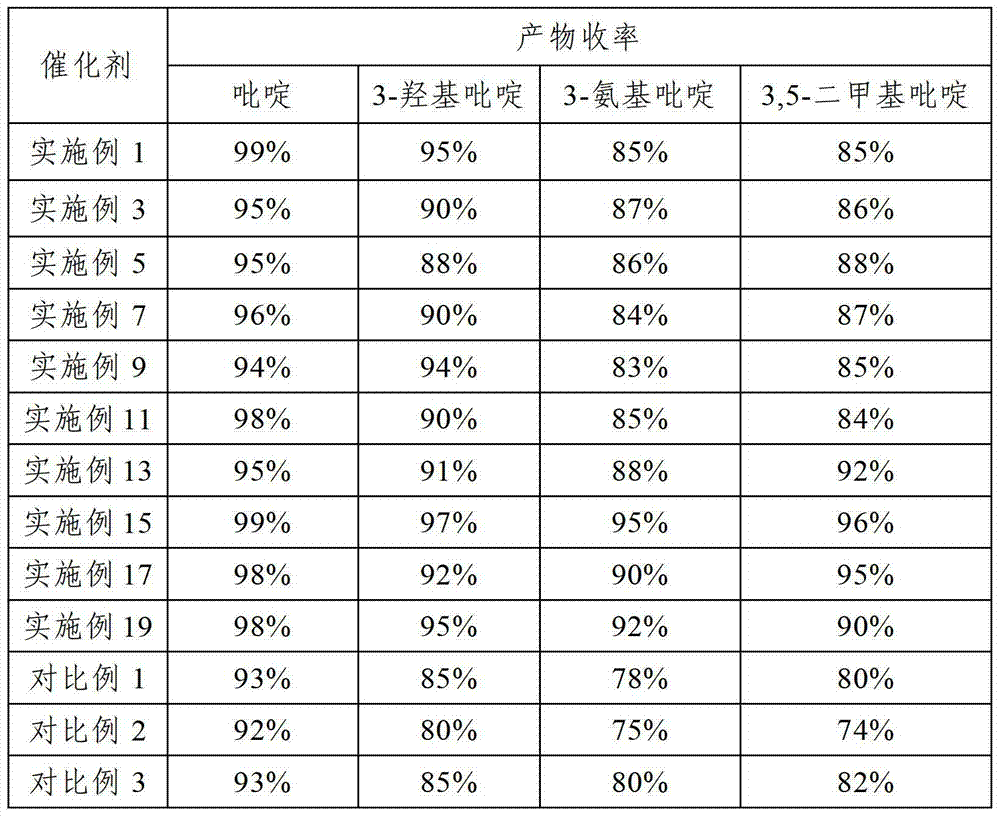

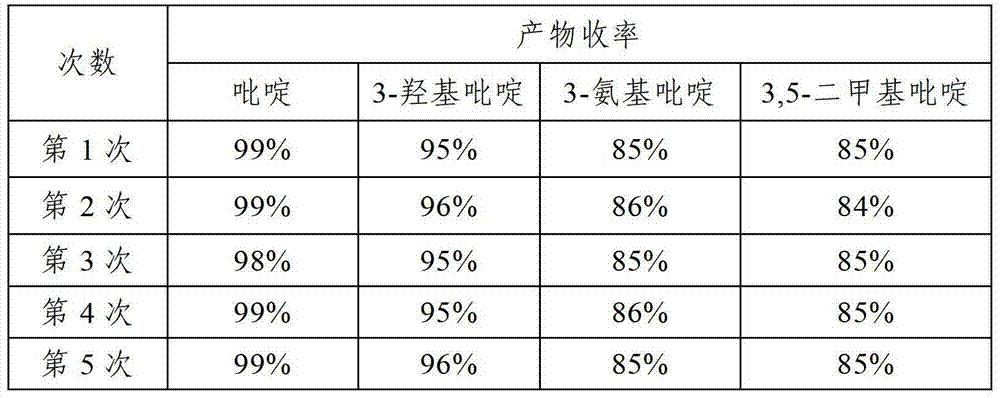

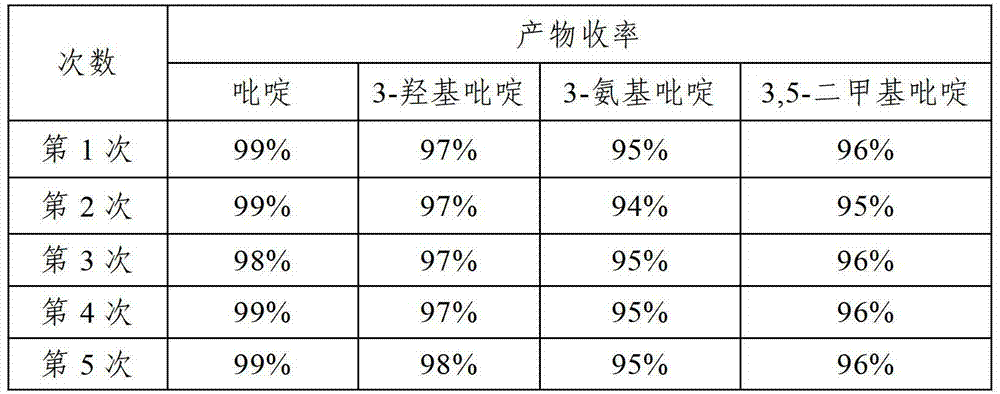

Examples

Embodiment 1

[0034] Step 1. Add 10g of activated carbon to HNO with a concentration of 12mol / L 3 Soak in the solution for 2 hours, then wash the soaked activated carbon with deionized water to neutrality and filter to obtain pretreated activated carbon; the particle size of the activated carbon is 200 mesh to 300 mesh, and the specific surface area of the activated carbon is 1000m 2 / g;

[0035] Step 2, dissolving ruthenium trichloride with a ruthenium content of 0.3 g and palladium chloride with a palladium content of 0.05 g in water, and stirring evenly to obtain 20 mL of a precursor solution;

[0036] Step 3: Weigh 9.65g of the pretreated activated carbon carrier described in step 1 and add it to the precursor solution described in step 2, impregnate for 2 hours under stirring conditions, and then adjust the pH value of the impregnation system to 9 with aqueous potassium hydroxide solution, After continuing to stir for 3h, filter to obtain a filter cake, which is washed with water un...

Embodiment 2

[0039] This embodiment is the same as Embodiment 1, except that the auxiliary agent is platinum, rhodium, cobalt or nickel, or two or more of palladium, platinum, rhodium, cobalt and nickel.

Embodiment 3

[0041] Step 1. Add 10g of activated carbon to HNO with a concentration of 15mol / L 3 Soak in the solution for 1 hour, then wash the soaked activated carbon with deionized water to neutrality and then filter to obtain pretreated activated carbon; the particle size of the activated carbon is 300 mesh to 400 mesh, and the specific surface area of the activated carbon is 1500m 2 / g;

[0042] Step 2, dissolving ruthenium nitrate with a ruthenium content of 0.5 g, cobalt nitrate with a cobalt content of 0.05 g, and platinum chloride with a platinum content of 0.05 g in water, and stirring evenly to obtain 20 mL of a precursor solution;

[0043] Step 3: Weigh 9.4g of the pretreated activated carbon carrier described in step 1 and add it to the precursor solution described in step 2, impregnate for 1 hour under stirring conditions, and then adjust the pH value of the impregnation system to 10 with potassium hydroxide aqueous solution, After continuing to stir for 2h, filter to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap