Non-setting adhesive injection auxiliary device

An auxiliary device and glue injection technology, which can be applied to devices and coatings that apply liquid to the surface, can solve the problems of high production cost, high scrap rate, high operation difficulty and strength, etc., and achieve a simple structure and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

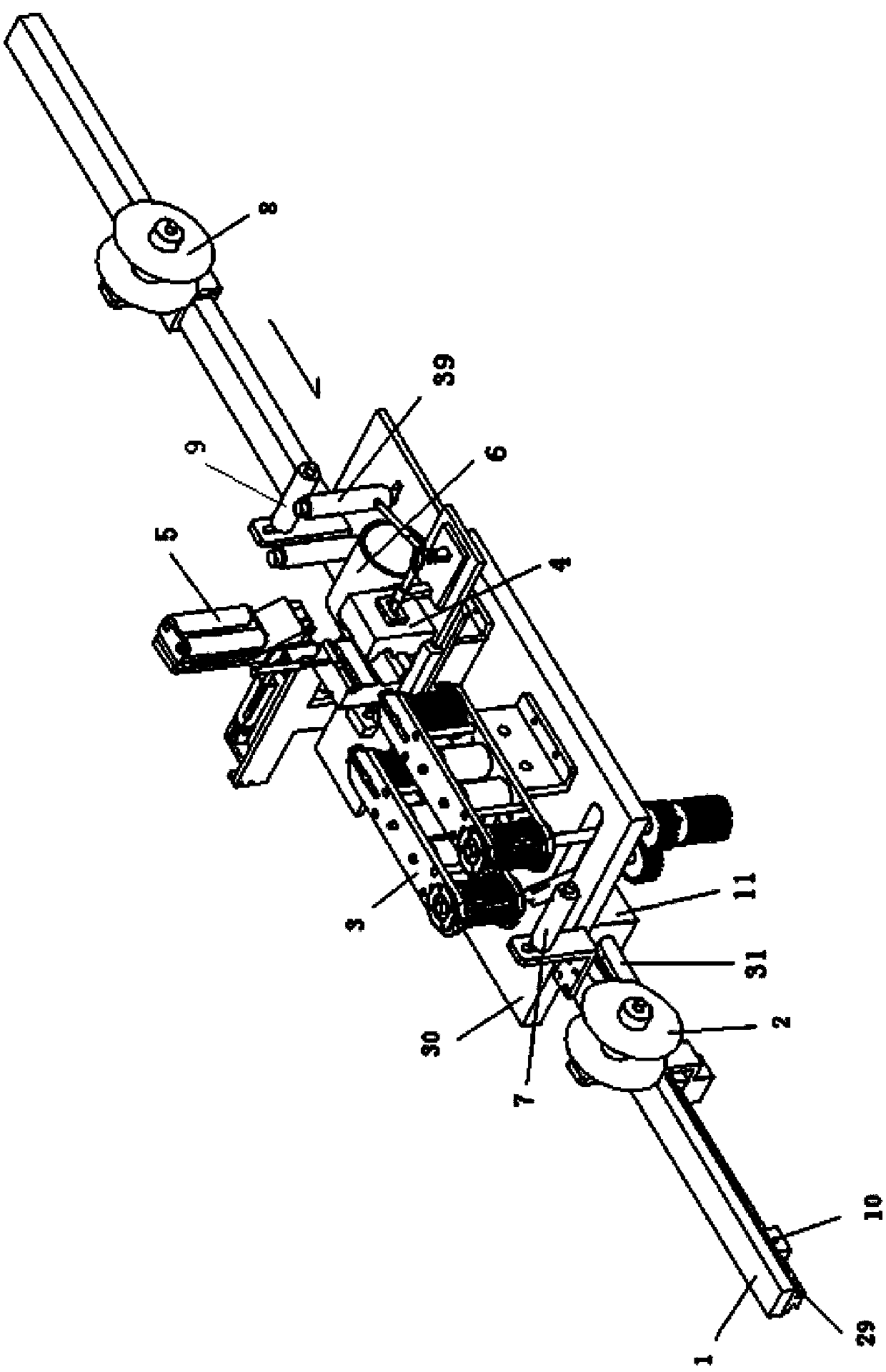

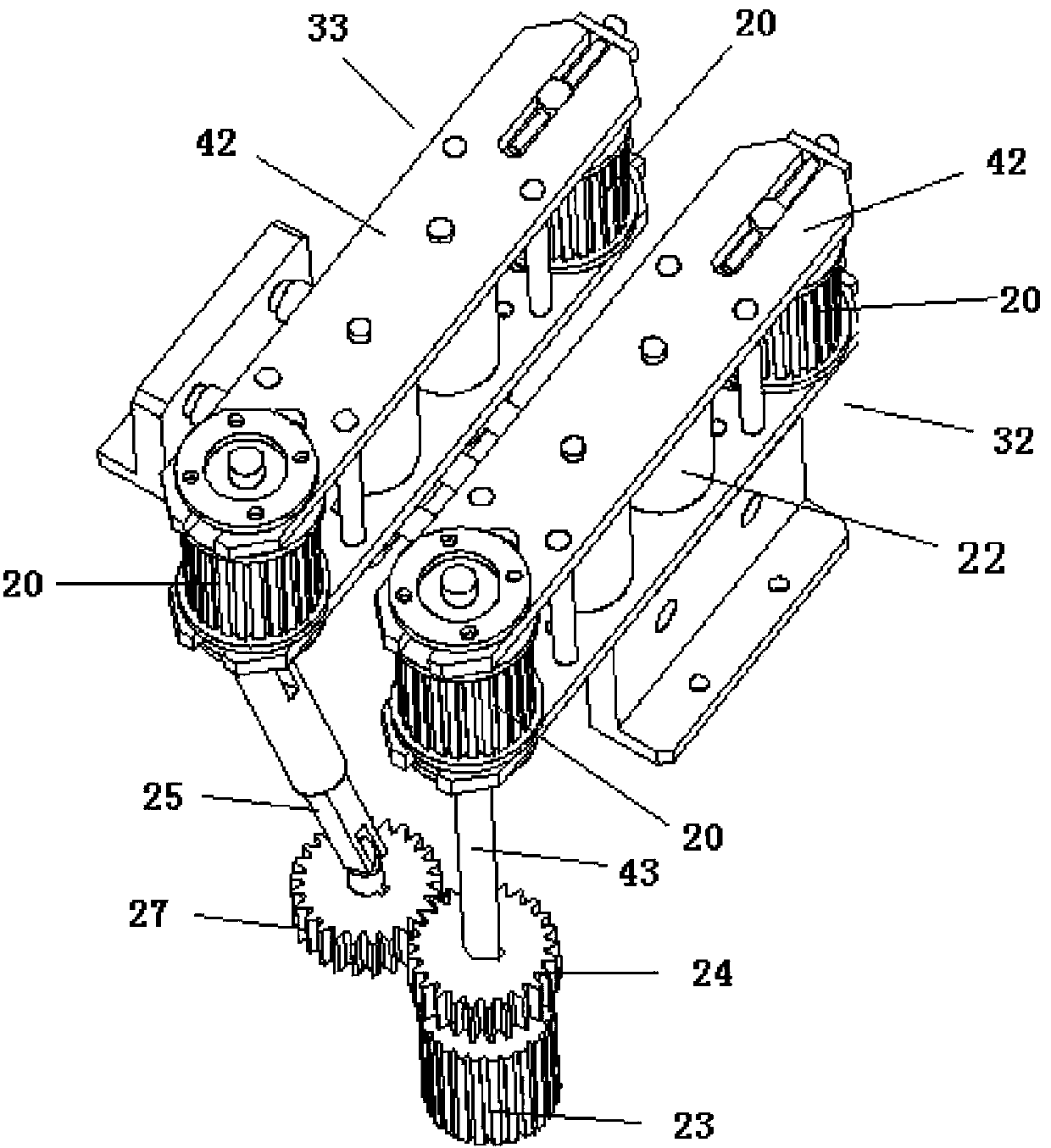

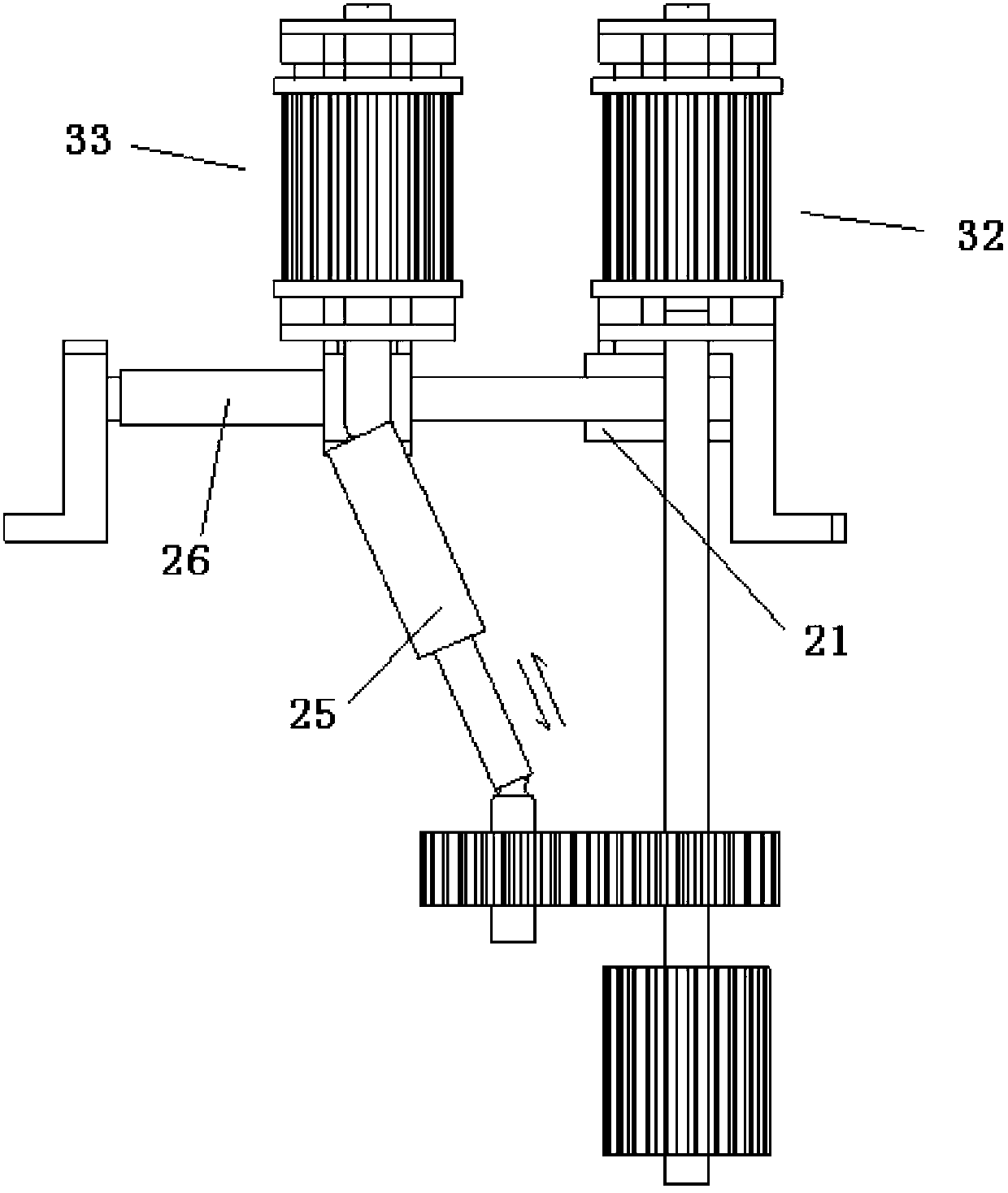

[0016] Referring to the accompanying drawings, it can be seen that the self-adhesive injection auxiliary device of the present invention includes a guide rail 1 with a chute 29 on the lower surface, a limit block 10 is provided on the chute 29, and the upper surface of the guide rail 1 is provided with The movable guide wheel 2, the base plate 30 and the fixed guide wheel 8, the upper surface of the base plate 30 are sequentially provided with a pulley mechanism 3, a product profiling jig 4, a coding sensing device 6 and a second guiding wheel 9, the coding sensing device One side of 6 is provided with a pressing mechanism 5 , and the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com