Production method of hollow metal jewelry

A production method and jewelry technology, applied in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve problems such as inability to achieve one-time molding, inability to adapt to large-scale production, and inability to vary in variety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] The present invention is a method for making hollow metal jewelry. In this embodiment, a method for making a hollow ring is adopted, and the method includes the following steps:

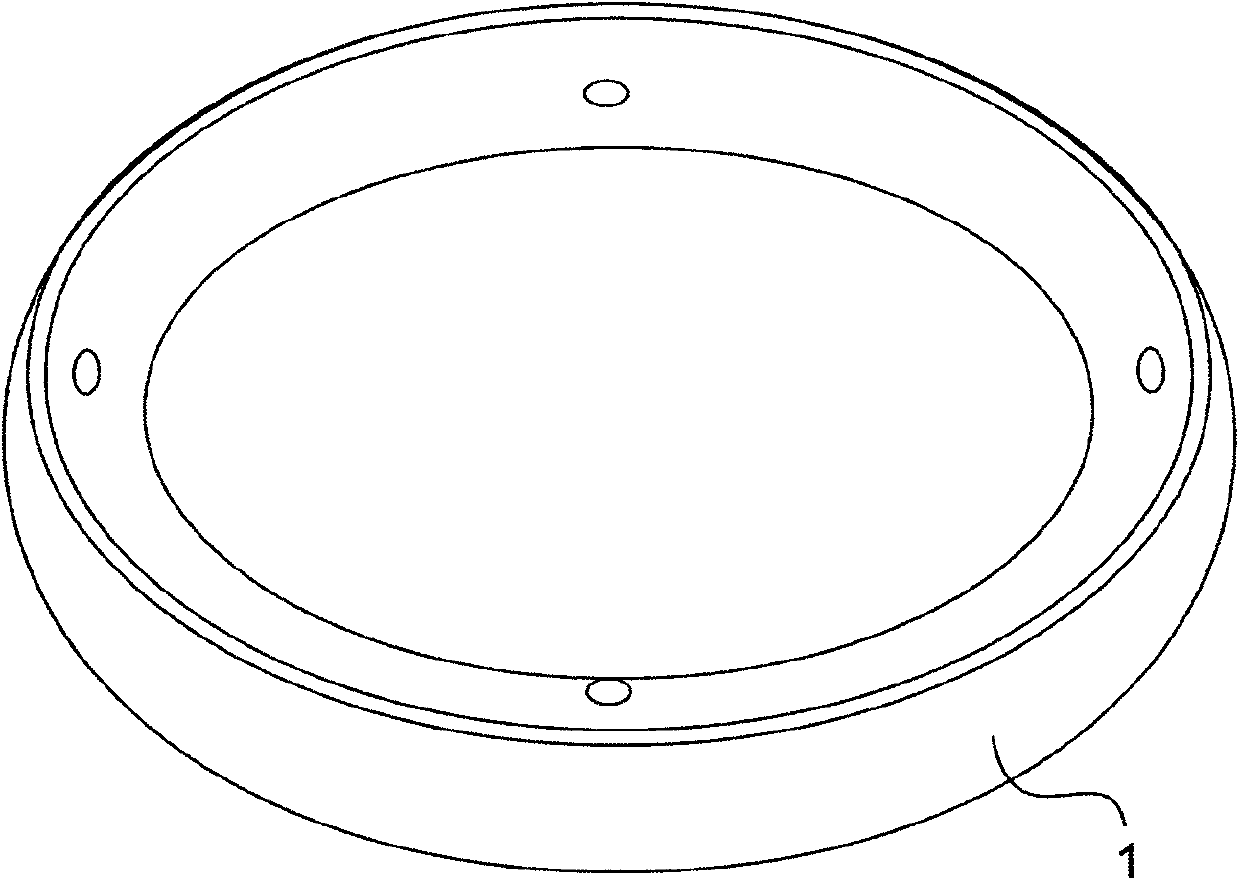

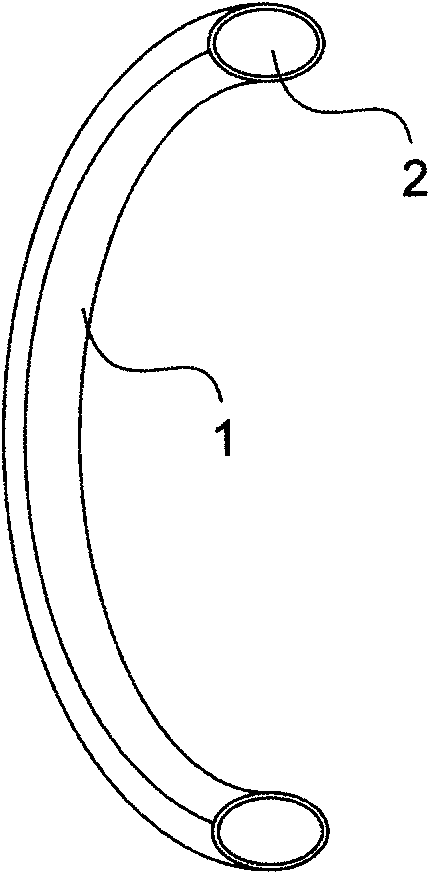

[0017] Pre-design and manufacture wax injection molds. The wax injection molds are made of steel molds. The wax injection molds include a shape wax injection mold and a hollow wax injection mold. Ring shape grooves are made on the shape wax injection molds. Ring shape grooves can be designed for various rings Shape, making ring hollow die groove on hollow wax injection mould, the diameter of ring hollow die groove is smaller than the diameter of ring shape die groove.

[0018] The water-soluble wax is injected into the hollow mold cavity of the ring on the hollow wax injection mold to obtain the water-soluble wax mold of the hollow part....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap